Overview

The steel industry presented Handling Specialty with the challenge of designing a solution that meets the unique technical and environmental demands of steel companies with blast furnace operations.

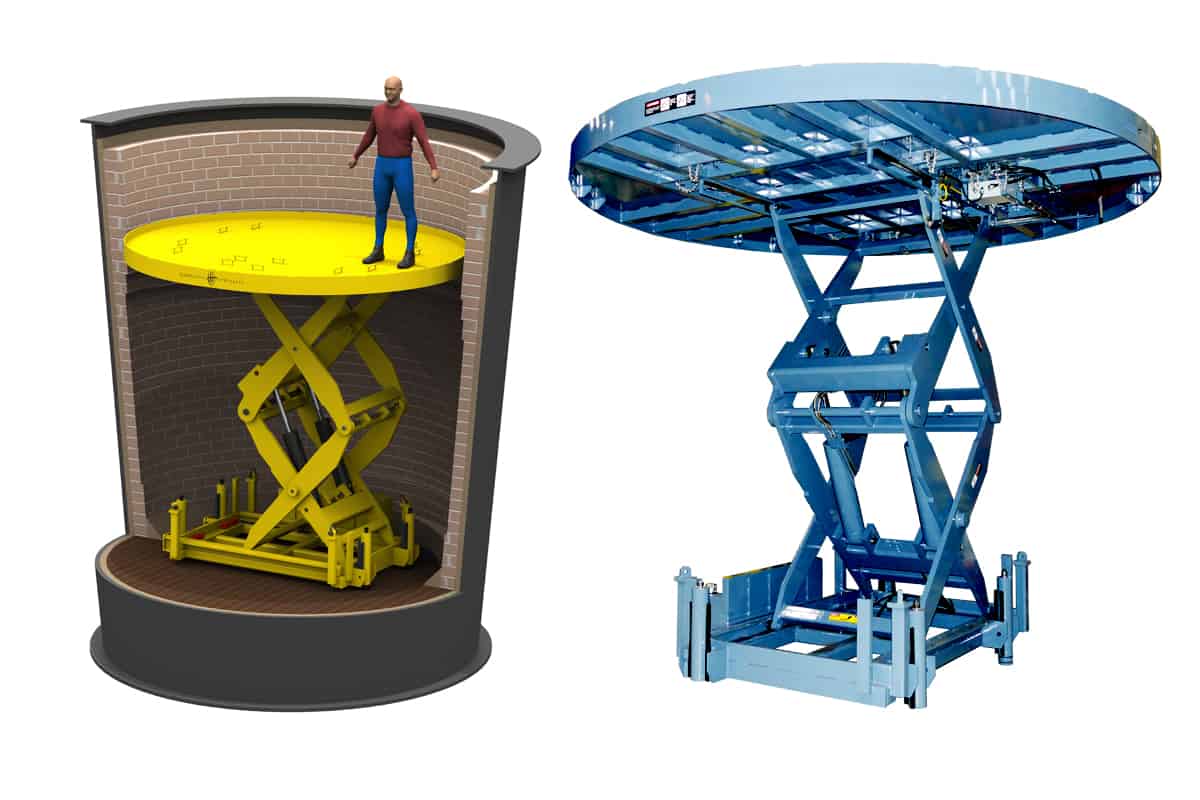

Since refractory firebrick in pour ladles requires continual replacement, a safe and efficient method for replacing the brick was needed. Handling Specialty’s ladle lifts replaced traditional scaffolding used in the re-bricking job. The lift is loaded into the ladle using a crane and can be moved to the next ladle requiring re-bricking. These two-stage scissor lifts are designed to withstand harsh melt shop environments. Since developing this solution in the early 80s, Handling Specialty has provided over 80 ladle lifts to steel factories across North America, with many of them still operating today.

These robust, heavy-duty, high-rise tables can be designed in capacities of up to 11,000 lbs. Due to the irregular shape of the ladles, the lift’s base and platform are customized to fit the client’s ladles precisely.

Features

- Heavy-duty high-rise table with custom profile top.

- Provides a safer and more efficient working environment.

- Special controls and protection for harsh environments.

- Lifting platform available flat or with optional perimeter kick plate.

Standard options include:

- Hardened fluid runs.

- Reinforced platform.

- Manual lowering valve.

- “Armored” HPU.

- Shackles for four-point lifting by overhead or jib crane.

Optional features include:

- Unique levelling legs.

- Flat or clip-on platform extensions.