Carrier Assembly with Hydraulic Lift

Overview The Carrier Assembly with Hydraulic Scissor Lift was designed specifically for our client. It is mounted to an overhead tugger arm and pulled through the assembly process, running intermittent operations – 35 cycles per day. The integrated scissor lift allows for precise positioning of the product at technician’s height. Features Scissor lift assembly

Self Propelling Lift for Steel Industry

Overview Handling Specialty was presented with a material handling challenge by steel giant Allegheny Ludlum to move steel coils through an existing narrow pit system. Fitting within 3/4” of the pit walls, the 50,000 lbs capacity lift measures only 64” wide and 84” long. Download the AGV Buyer’s Guide Features 50,000 lb capacity lift. Self-propelling […]

Tow Line Carrier for Farm Equipment

Overview Fifteen of these robust, indexing towline carriers were designed and built to tow the line of the lower main frames of combines as they are assembled at the farm equipment manufacturer’s facility. Each unit is capable of carrying up to 50,000 lbs. These carriers will travel at 6 MPH and are designed for strength […]

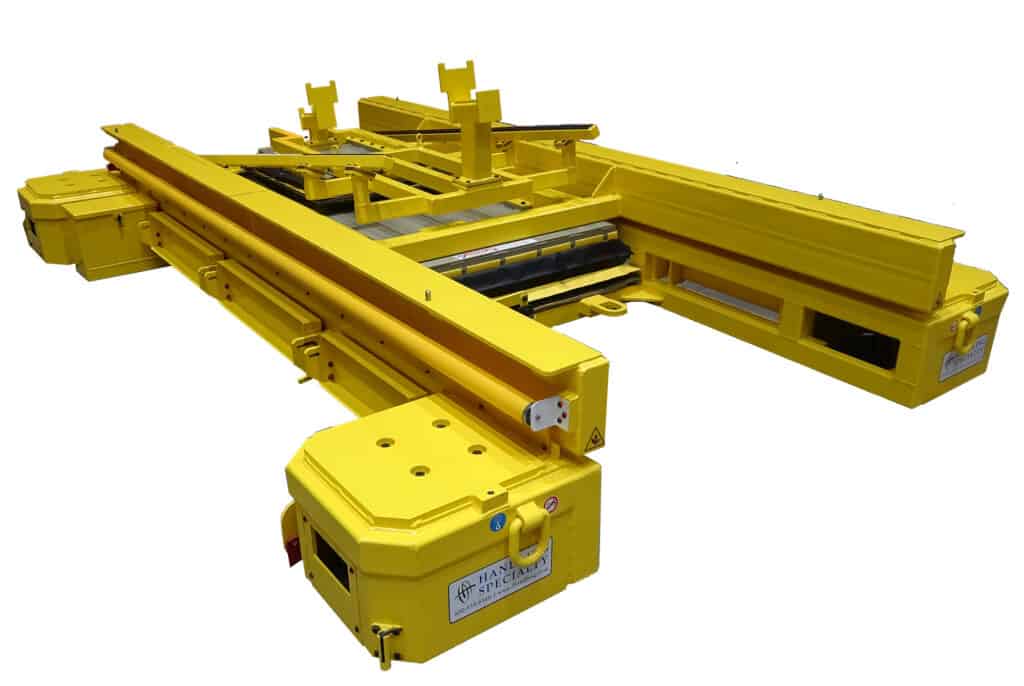

Modern Towline Carrier

Overview These eight towline carriers are equipped with two battery-powered hydraulic scissor lifts, one atop the other, to perform one lift per day, 10 hours a day, 240 days per year. They will be used in the assembly of heavy-duty farm equipment and come with two types of tooling. The towline carriers include fixtures to […]

Blank Handling Carts for Automotive

Overview These Blank Handling Carts for the automotive industry receive a stack of steel or aluminium blanks from a fork truck and then index along tracks into the destacking cell. Blanks are removed from the cart until the stack is depleted. The empty cart returns to the load position. The customer will install a servo […]

Towline Carts for Automotive Assembly

Overview Handling Specialty engineered and manufactured custom towveyor carts that move both horizontally (by towline) and vertically (with two electromechanical lifts) to meet the ergonomic and assembly needs of an automotive production line. The front lift is used to hoist the front axle and engine assembly into the vehicle body, while the back lift inserts […]