90 Ton Heavy Duty Rail MRO Drop Table

Overview Once the rail car has driven on to this 90 ton heavy duty rail MRO drop table and the wheelsets have been disengaged, it rises and lowers the rail wheelsets and bogies on four mechanical ball screw posts. This unit also traverses the service rails moving forward and backward to assist in removing the […]

25 Ton Drop Table and Traction Motor Dolly

Overview Our rail equipment dealer received a purchase order for one 25-ton Drop Table including a traction motor dolly, locking bar pockets, packaging and freight, installation, commissioning, and training. This Drop Table system will be used to remove and re-install wheelsets on freight cars. Drop Table: The main drop table trolly uses an HPU to […]

10 Ton Drop Tables for Rail Maintenance

Overview These 10-ton Drop Tables for rail maintenance travel below the railcars to remove and replace wheelsets. The body supports lift the train car at its lifting pads, allowing technicians to loosen the wheelsets while the bogies rest on the drop table service top. Then the drop table lowers the wheelsets and moves them along […]

Heavy Duty Drop Tables for Rail Maintenance

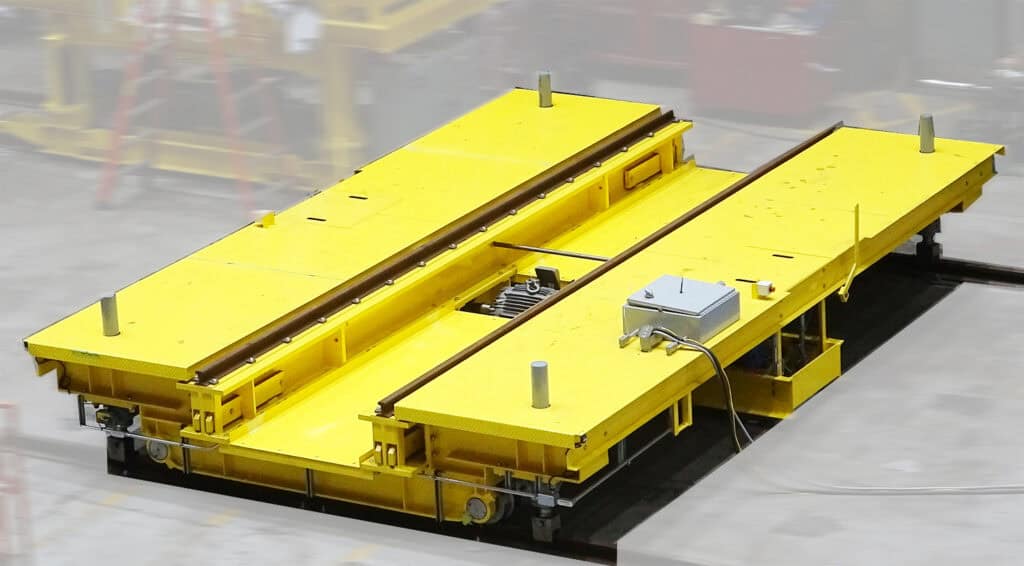

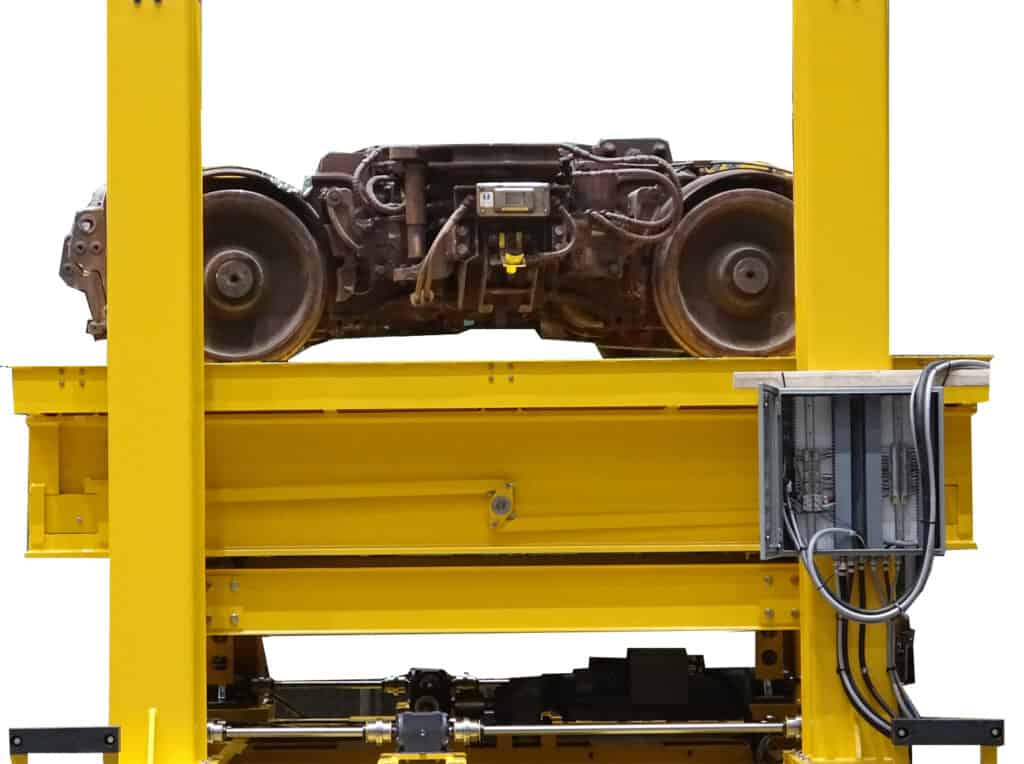

Overview The Double Drop Table is a fully engineered mobile hoist system that will facilitate the replacement of an existing rail car wheelset with a new wheelset. The Double Drop Tables traverse on a set of rails laid perpendicularly and below the elevation of the rail car service tracks in a trench of prescribed depth. […]

50 Ton Drop Table

Overview A large railroad maintenance facility in the United States required a 50-ton drop table to facilitate the changeout of traction motors on its locomotives. Handling Specialty custom engineered and designed a 50-ton drop table based on an original heavy-duty Whiting Corporation design. Whiting pioneered the development of the drop table concept. Wheelset changeouts are […]