Electro-mechanical Scissor Lifts for Automotive Industry

Overview Handling Specialty ‘s custom engineered scissor lifts for the automotive industry were built to lift personnel during the inspection of vehicles in the manufacturer’s paint shop. These two units run electro-mechanically, compete 1200 cycles per day, 364 days a year and are lagged to the purchaser’s facility floor. Features Control panel PLC with HMI […]

Assembly Platform for Energy Industry

Overview Handling Specialty custom-engineered and manufactured this pit-mounted, vertical assembly platform to operate intermittently. This vertical platform rises around the energy turbine as it is assembled, and can accommodate several sizes of turbine. It raises and lowers on three scissor lifts via the motor starter panel mounted on HPU. Controls for up/down, start, and E-stop […]

Overhead Belt Lift for Material Handling

Overview These four overhead belt lifts will perform 3 cycles per hour, 24 hours per day, 300 days per year, and be used in a shuttle application at the assembly site, attached to the existing overhead conveyor structure that will raise and lower trailers during the painting process. These lifts raise and lower to precise […]

Multi Stage Scissor Lift For Aerospace

Overview The multi-stage lift performs intermittent operation of 10 full cycles per day. Features Two (2) spiralift actuators ILR250 (double pitch). Two (2) servo-motors. One limit switch for Up travel. One limit switch for Down travel. One limit switch for Up/Down overtravel. One limit switch for each spiralift.

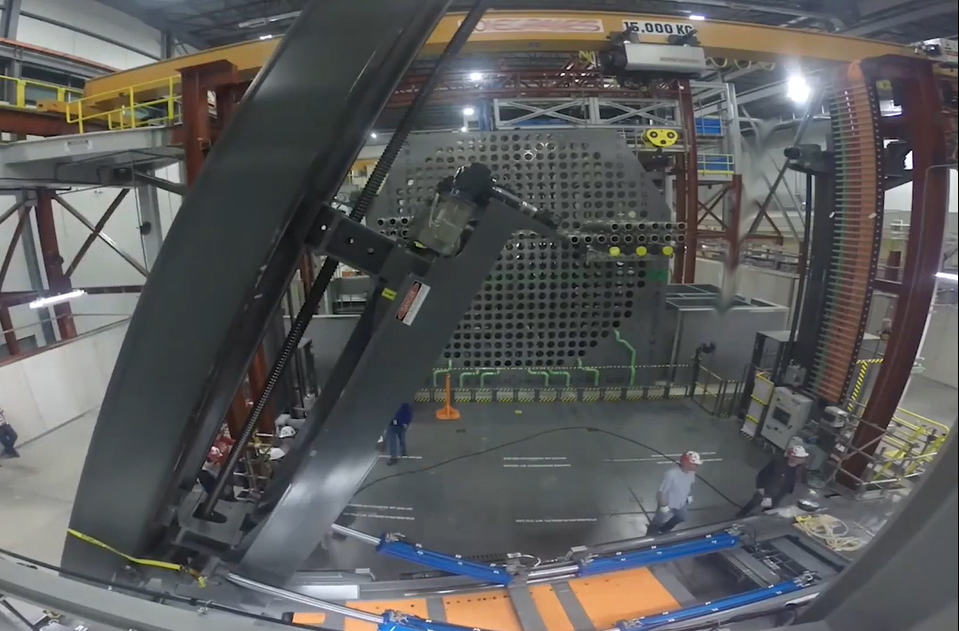

Retubing Tool Platform-Column Handler

Overview Retubing tool platform-column handler Secured to a four-post lift, the retubing tooling platform-column handler performs the removal and replacement of reactor components. Otherwise known as the re-tube and feeder replacement phase. It accomplishes this task in part by utilizing its hydraulic tilt feature. The tooling platform and column handler are operated remotely from the […]

Overhead Belt Lift for Material Handling

Overview Working 48 cycles/hour, 16 hours/day, 280 days/year, these 12 electro-mechanical overhead belt lifts were designed to be integrated into an automotive manufacturer’s overhead conveyor system to move car and truck bodies through the assembly line. This belt lifts lower around the vehicle body, and custom tooling secures the underside, then the belt lifts raise […]