Locomotive Nosecone Access Platform

Overview These nose cone maintenance platforms were custom engineered to meet the customer’s specific application requirements and are used by maintenance personnel to access the windshield area to inspect, clean, repair and replace components. The nose cone platforms travel on the shop’s running rail and are positioned manually or via fork truck. The lift and […]

Rail Bogie Assembly Work Platform

Overview This rail bogie assembly work platform was custom-engineered for strength and structural rigidity to perform flawlessly in the harsh environment of a rail assembly plant. Features The Bogie Assembly Work Platform includes: Four screw jacks with gear motors and brakes. Four bellows covering the screws. Pull down bar for cylinder rod attachment. Fixed rotation […]

Rail Truck Inspection-Testing Workstation

Overview This free-standing 4-post electro-mechanical screw lift was custom-designed to lift and support rail trucks for a specific client’s truck measurements and application. Each lifting jack is powered by its own motor and synchronized to each other to ensure level lifting. Lifting frames for the trucks are included on each jack allowing the wheels to […]

Industrial Electric Jacks

Overview An order of 3 pairs (6 Jacks) of Industrial Jacks were delivered to our customer. Pairs are designed to work in tandem with one another, allowing for lifting capacities of up to 7 Tons. An electrical panel and master control unit are installed on one of each two Jack sets, which synchronizes the movements […]

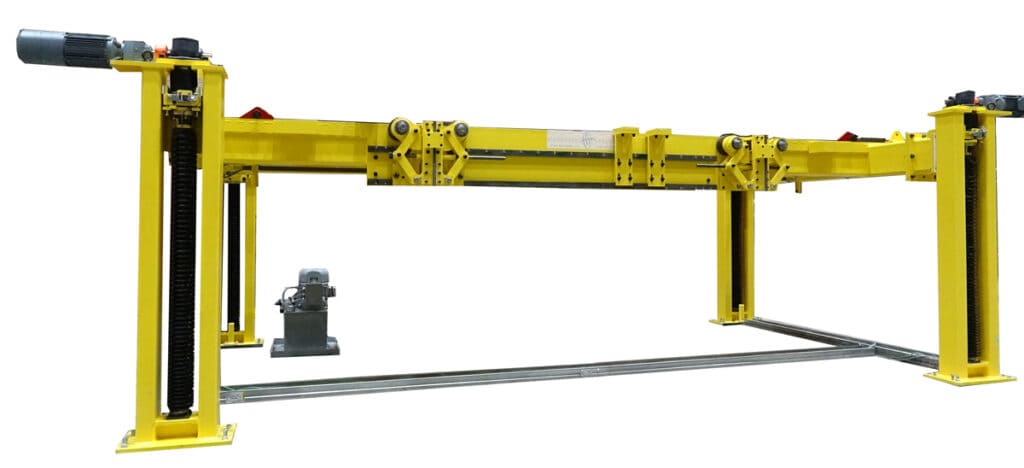

Rail Cable Fixture Rotator

Overview This custom cable fixture rotator designed and built for a rail industry client is used to manufacture cable trays for locomotives and coaches. It is used during the assembly of cable carrier trays for locomotives and other rail vehicles. If you are manufacturing equipment for LRT, Monorail or Heavy rail, the Handling Specialty cable […]

Lifting Frames for Rail car Assembly

Overview When in application, the lifting frames are used for lifting rail vehicles in the customer’s assembly building by lowering the frames via an overhead crane around the train car or locomotive, then securing the undercarriage with the frame’s manually cranked steel support arms. Once secure, the two frames are lifted again by the crane […]