Streamline Your Processes with Vertical Assembly Solutions

Assembly, MRO, and manufacturing organizations are constantly seeking ways to streamline their processes and improve safety and efficiency. One solution that has gained significant traction is vertical assembly. Vertical assembly is the process of integrating various stages of manufacturing vertically, thereby providing a seamless and efficient workflow. Explore the benefits and key components of vertical […]

Expert Tips for 4-Post Electromechanical Lifting Systems

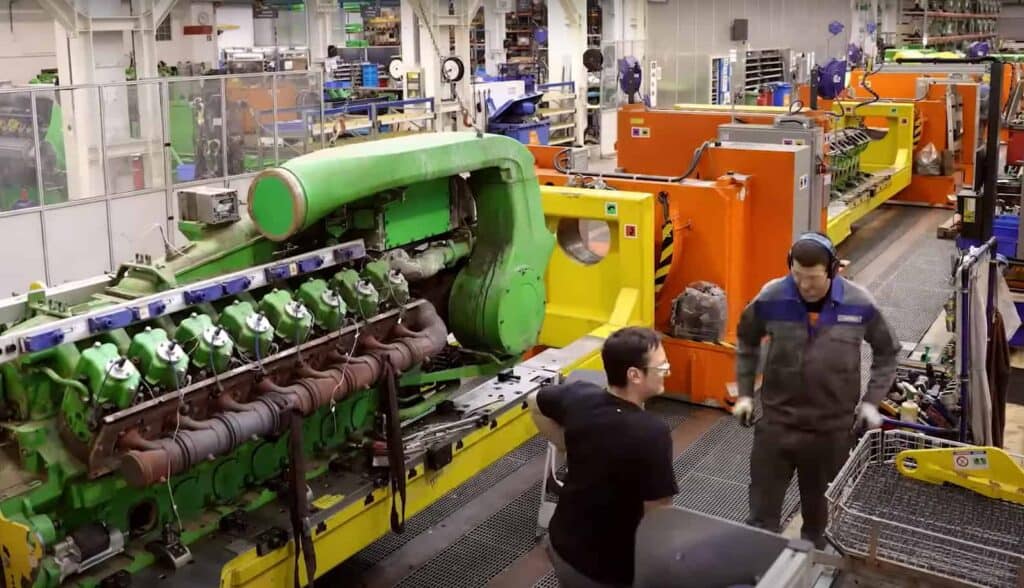

What are the advantages of using 4-post electromechanical lifting systems? 4-Post electromechanical lifting systems offer superior stability, versatility, and ease of use. They provide secure lifting for heavy loads, precise positioning control, adaptability for various industries like automotive, power generation, and aerospace, and increased safety features compared to traditional lifting systems. Introduction in an assembly, […]

Streamline Operations with Custom Work Positioners

Key Highlights Custom work positioners offer ergonomic material handling solutions that can be customized to meet specific needs They play a crucial role in modern facilities, improving efficiency and reducing the risk of work-related injuries Different types of work positioners are available, including adjustable work positioners and inverted work positioners Implementing custom work positioners can […]

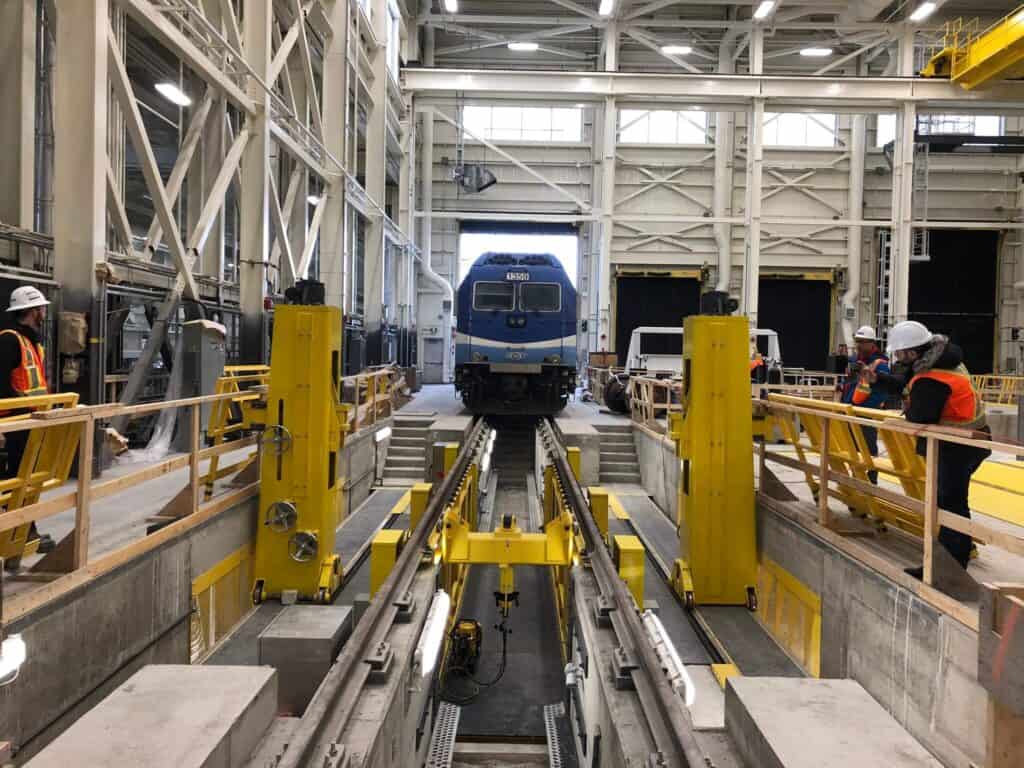

Railcar Maintenance Equipment Explained

Key Highlights Railcar maintenance equipment is essential for ensuring the longevity and proper functioning of rail vehicles. Different types of maintenance equipment are used in railcar maintenance, including lifting equipment, traversing equipment, turntables, rotators, and more. Safety and compliance with industry standards are crucial when operating railcar maintenance equipment. Effective maintenance planning and scheduling can […]

Maximizing Manufacturing Efficiency: The Benefits of Automated Guided Vehicles (AGVs)

Efficiency, productivity, safety, and sustainability are paramount concerns for businesses aiming to stay competitive. One technological innovation that addresses these challenges head-on is the integration of Automated Guided Vehicles (AGVs) into manufacturing processes. The benefits of Using Automated Guided Vehicles in Manufacturing, with their ability to navigate autonomously and perform various tasks, can significantly enhance […]

Navigating the Future: Innovations and Challenges in Automated Guided Vehicles

The future of Automated Guided Vehicles (AGVs) seems secure. AGVs have long been at the forefront of industrial automation, and the innovations and challenges in automated guided vehicles are revolutionizing assembly and manufacturing processes. However, as technology continues to evolve rapidly, the future of AGVs is poised for even more remarkable transformation. From advancements in […]