Carrier Assembly with Hydraulic Lift

Overview The Carrier Assembly with Hydraulic Scissor Lift was designed specifically for our client. It is mounted to an overhead tugger arm and pulled through the assembly process, running intermittent operations – 35 cycles per day. The integrated scissor lift allows for precise positioning of the product at technician’s height. Features Scissor lift assembly

Assembly Line AGV

Overview The Assembly line AGV was designed and manufactured by Handling Specialty to move product through the assembly line process while parts are affixed at several cells. The scissor lift assists in creating an efficient, safe and ergonomic solution to the assembly line. Features Hydraulic scissor lift. Lift operating foot pedals on two sides. Polyurethane […]

Guided Vehicle Assembly Line Carrier

Overview This guided vehicle assembly line carrier was designed/built for intermittent Operation (16 hours per day operation), 40 per day (lift), 480 per day (traverse – approximate 14’ between stations), 16 hours between charges, and five days per week operation. These manually Guided Vehicles carry and lift product during assembly operations. Features Two (2) Limit […]

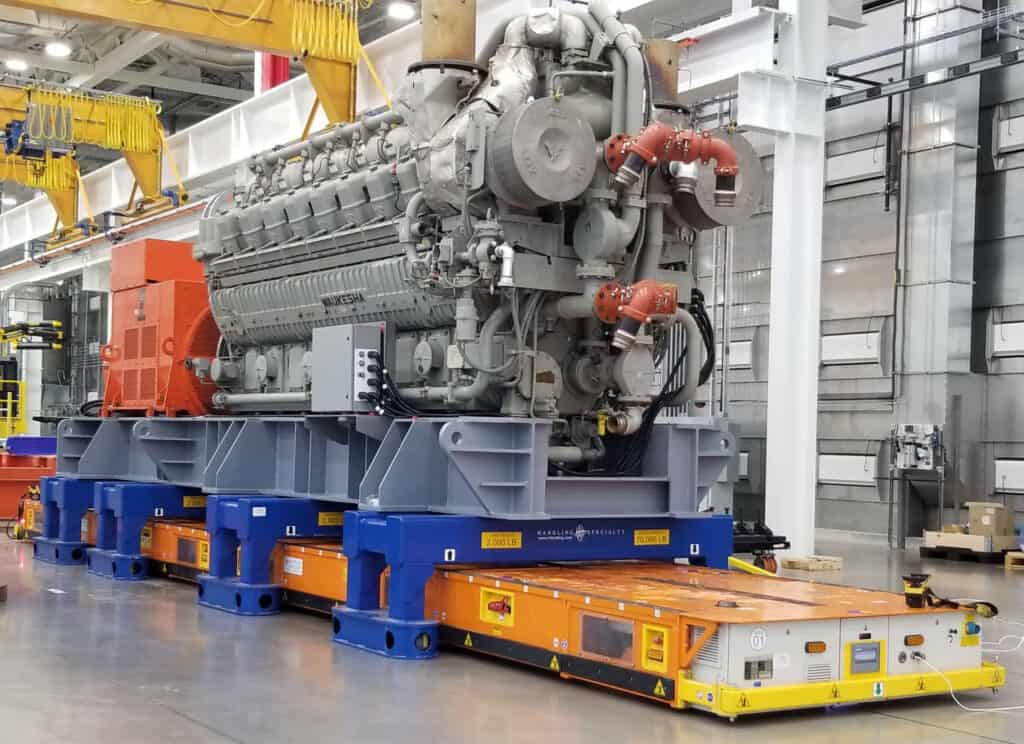

200,000 lb. AGV

Overview Using two 100,000 lb. AGVs in tandem, a customer can place up to 200,000 lbs. on the unit to be moved through the assembly line. Engineered and manufactured to lift and precisely position engines for assembly and maintenance purposes, Handling Specialty’s 200,000 lb. Manually Guided Vehicles employ modular traction/steering drives that are bolted to […]

100,000 lb AGV

Overview Engineered and manufactured to lift and precisely position engines for assembly and maintenance purposes, Handling Specialty’s 100,000 lb. Manually Guided Vehicles employ modular traction/steering drives that are bolted to a fabricated steel frame. The traction/steering modules simplifies the operation and maintenance of the engine transporters. The Traction/Steering modules provide the force to move the MGV. Each […]

Lifting Beam for Nuclear

Overview Typically, more than 200 fuel rods are bundled together to form a fuel assembly in a nuclear facility. These rods need to be removed to make room for new rods with a full complement of nuclear fuel. In order to remove the rods, custom material handling equipment has been designed and built by Handling […]