Scissor Lift for Robotic Paint Cell

Overview A “Big Three” automaker approached Handling Specialty to custom engineer, design, and manufacture explosion-proof, high-precision scissor lifts for one of their robotic automotive paint facilities. In this solution, the fully-assembled car body enters an offline inspection booth by way of a power roller conveyor. The body is transferred onto the paint station’s tandem scissor […]

Custom Scissor Lift for Robotic Welding Cell

Overview At an automotive assembly plant in Vance, Alabama, Handling Specialty custom engineered and manufactured scissor lifts that were integrated into the production line for welding structural components to automotive bodies. The transfer process in and out of the workstation dictated a change in elevation along with a high degree of accuracy and speed. Using […]

Manually Guided Vehicles for Assembly

Overview A manually guided vehicle for assembly processes creates a safe and efficient workspace while moving products through work cells. This order was for seven (7) manually guided vehicles (MGVs) to be used in the assembly of military-style side-by-side. A military side-by-side is an ATV deployed by military forces responding to missions where heavier equipment […]

Custom Scissor Lift for Theme Park

Overview Handling Specialty was called upon to deliver a unique three-stage, high-rise custom scissor lift for a giant monster special effect. The pit-mounted scissor lift moves upward to propel the monster up, out, and down over pedestrians on a 5-foot rotor bearing, with the head spitting fire and saliva during its travel. The hydraulic lift […]

6,000 lb Lift for Die Positioning

Overview Handling Specialty was approached by a Tier 1 supplier to the automotive industry to custom engineer and manufacture a 6,000 lb capacity lift to be used by technicians to ergonomically position dies for maintenance. Features Synchronized level lifting via the electro-mechanical driveline. Zero creep at any elevation for sustained positioning. The design incorporates die-set […]

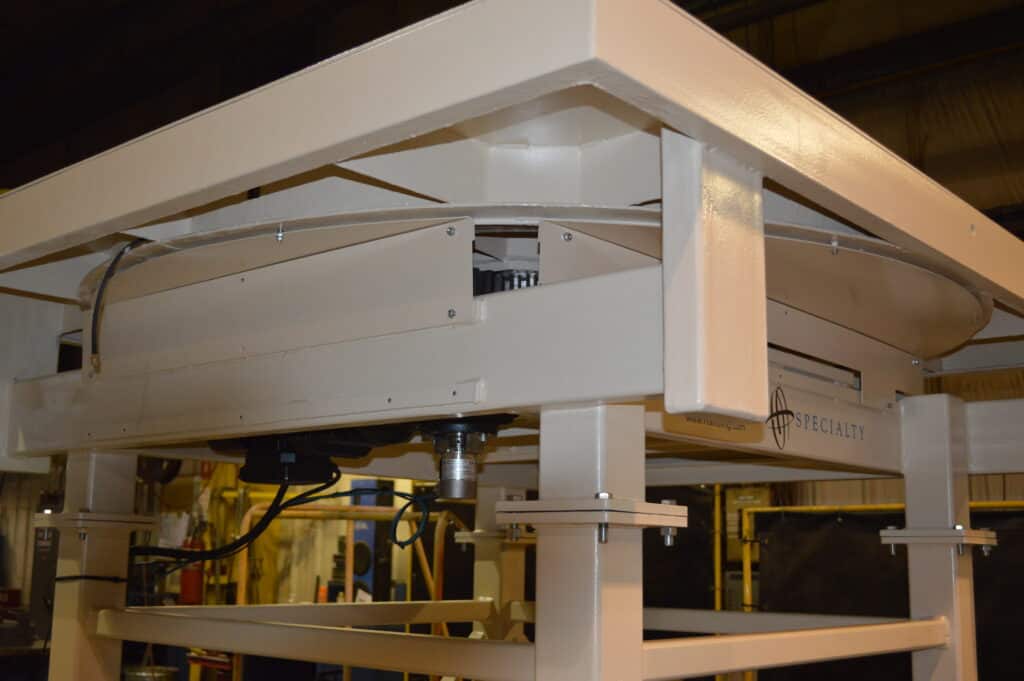

Wind Tunnel Turn Tables

Overview A major wind tunnel engineering firm required two turntables for a wind tunnel they will place in a Texas University. Handling Specialty’s designs offered the project everything they’d asked for, including controls which allow the operator to customize the stop-position of the rotating top, set designated stops and run clockwise and counter-clockwise.