Four Post Lift System for Ultrasonic Inspection

Overview A major aerospace and defence integration firm approached Handling Specialty to custom engineer and manufacture an automated ultrasonic inspection system to inspect the exterior surface of a rocket shell using a robot. The lifts/robotic units work in tandem: one robot repeatedly raises and lowers inside the rocket shell on the scissor lift while the […]

Paint Booth Lift for Railcar Facility

Overview Handling Specialty custom designed and manufactured eight self-propelled personnel lifts for a paint booth in a North American railcar manufacturing plant. Safety was the primary consideration in the design of the personnel lifts. Features Self-propelled on upper and lower rails. Travel at 15 fpm. 60” platform extension. Traverses 100’ on rails.

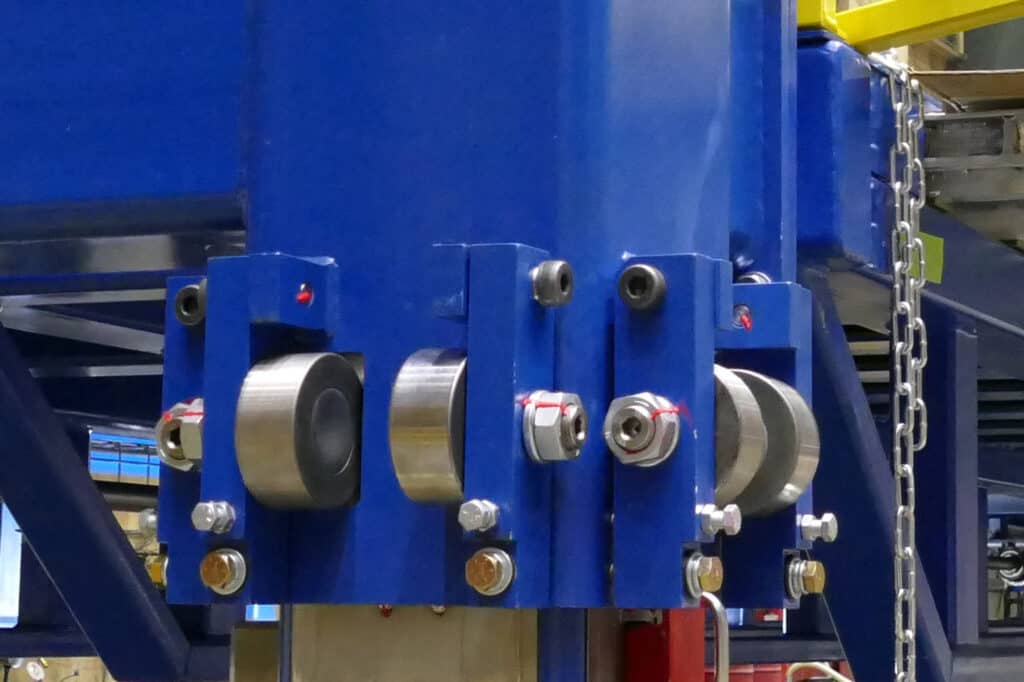

Four Post Lift for Rail Truck Assembly System

Overview Handling Specialty worked collaboratively with a transportation company to design and manufacture equipment to be used in the testing and assembly of railcar bogies (also called wheelsets or trucks). This was a custom project requiring extensive collaboration between the customer and Handling Specialty’s engineering team to ensure the equipment met the customer’s precise requirements. […]

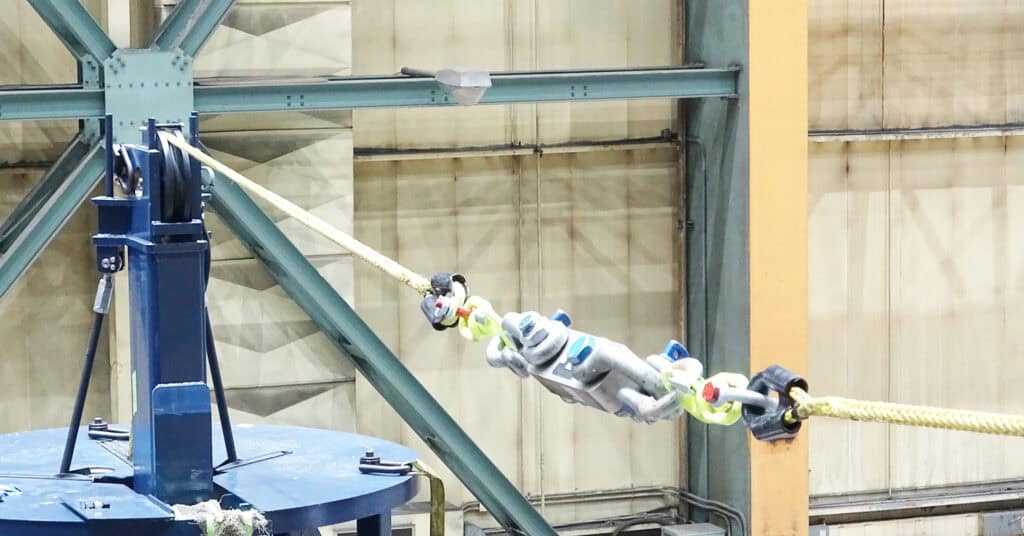

Theater Acrobatic Net Lift Equipment

Overview This custom, acrobatic net lift equipment anchored to the theater floor consists of two towers that flank a circular stage designed and built to the specific requirements of a theater company’s choreography at their themed resort. As are many of Handling Specialty’s custom equipment packages, this was engineered as a turnkey solution for their […]