Scissor Lift Design, Dimensions and Sizes

Scissor Lift Design, Dimensions and Sizes

Scissor Lift Design and Dimensions are determined by the type of work the scissor lift is specified to undertake. These include the power consumption required to operate, the maximum load-lifting capacity, elevation height, etc.; these will determine the dimensions of a scissor lift. The primary purpose of a scissor lift is to raise vehicles or machinery for undercarriage work or carrying personnel to position them at the correct location and elevation for service or assembly work. Scissor lifts have x-shaped pillars attached to the lift table, making them different in design and function from a boom lift. A boom lift has an extending arm to lift the platform enclosure to the desired height.

Scissor lift models can be designed to use hydraulic, electric, diesel, or pneumatic power to operate.

- Hydraulic scissor lifts work using a motor that pushes pressurized oil from a reservoir into hydraulic cylinders to lift the platform.

- Electrically powered scissor lifts are commonly used in indoor areas as they have no emissions for medium-duty work.

- Diesel-powered lifts are well suited for heavy-duty outdoor use, such as construction or mining.

- Pneumatic lifts utilize air pressure to lift loads, making them the most environmentally conscious of designs.

Below are the various types of scissor lifts:

Rough terrain scissor lifts are diesel-powered lifts for handling heavy-duty outdoor work. They are fitted with four-wheel drive mechanisms with positive traction control suitable for harsh terrains.

Electric scissor lifts: used mainly for medium-duty indoor work in flat surface areas due to low emissions and minimal noise. Electrically powered scissor lifts can be fitted with hydraulic or pneumatic pumps for lifting loads.

Scissor lift design became more focused and specialized as industries grew and designs were adapted to meet specific lifting needs. As a result, manufacturers such as Handling Specialty have become leaders in the custom design and manufacture of scissor lifts across many industries.

Understanding the different types of scissor lifts and their applications is the first step before delving into the scissor lift schematic designs—their operating environment, power requirements, and mechanism influence how they are specified and manufactured. In the following sections, we will provide an overview of scissor lift components, what governs the overall dimensions of a scissor lift, and the purpose of each of those parts.

Lifts are classified into two main categories:

- The type of energy the scissor lift uses

- The type of utilization.

These two factors are the main components in determining how to design a scissor lift.

Lifts classified according to the energy applied include hydraulic lifts, electric lifts, diesel lifts, and pneumatic lifts.

Lifts categorized according to their usage are boom lifts, scissor lifts, and vehicle lifts.

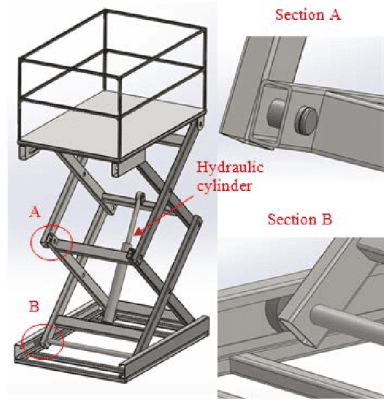

When it comes to the design and fabrication of scissor lift models, many components are common in all scissor lifts designs regardless of capacity, energy consumption, or the type of work it does.

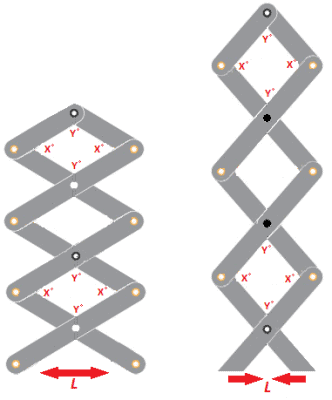

Scissor lifts apply the pantograph mechanism, a series of connected and intersecting arms that elongate when an operator works the lift. By closing the distance between the arms at the base, the platform raises. As the distance increases, the platform lowers. Scissor arms are generally made of steel which is strong enough to withstand medium-duty and heavy-duty loads.

This lifting table holds materials or personnel and lifts them to desired heights. They remove the need for workers to lift loads and reduces cases of bodily injury. The top platform connects to the scissor arms and is raised or lowered electrically, with hydraulic cylinders, air pressure, or a diesel engine.

- Scissor mechanism – The power source raises and collapses the pantograph supports to lift and lower loads.

- Screw mechanism – The lift table moves along the screw length as it rotates

- Rack and pinion mechanism – the table drags along the pinion track through rack rotation

- Telescoping mechanism – Linear actuators move the lifting table

scissor lift’s base serves as a foundation for the scissor arms and top platform. It’s made of fortified metal frames to withstand heavy loads without buckling or toppling over. In some models, rollers or wheels attached below the base allow the operator to move the whole equipment to wherever needed. Occasionally, these bases act as manually guided or automatically guided vehicles to reduce operator injuries and increase efficiency.

Cylinders: If it’s a hydraulic lift, cylinders filled with hydraulic liquids are attached to the equipment. Pneumatic lifts utilize pneumatic pump cylinders containing pressurized air to power the lift.

Power source: Scissor lifts use hydraulic, pneumatic, diesel, or electric power to operate. The power source can be attached to the scissors structure through a self-contained motor or remote-controlled power centre.

Valves: The down valve controls the flow of hydraulic fluids and compressed air, while the flow control valve manages the platform’s descent speed.

Safety features: All scissor lift designs have to implement safety features according to OSHA regulations. Common safety considerations are:

- Release locks – To lock in the top platform and scissor arms when the lift malfunctions. This feature prevents sudden drops.

- Pinch protector guards are pressure-sensitive guards that stop the tabletop from lowering if the lifting mechanism detects an obstruction.

- Fall protection systems – Such as guard rails, lanyards, and PPE.

In the final design of a scissor lift, the following factors come into consideration:

- Design Functionality.

- Ease of manufacturing.

- Material and fabrication cost.

- Lifting capacity – this is customizable to the client’s application requirements.

The design functionality of a scissor lift looks into the safety, weight lifting capacity, lift height, load stability, platform size, and loading method. These factors determine how a scissor lift will be used and if its design is safe and suitable for the defined application.

Also known as Design For Manufacturing (DFM), this principle works to produce a refined product at lower costs. This method involves designing scissor lifts that perform optimally and reduces the price of manufacturing.

Economic availability of raw materials such as steel and fabrication techniques also determine the design of scissor lifts. If raw materials are scarce, fabrication of scissor lifts becomes expensive, forcing manufacturers to produce simple, inexpensive designs. Materials availability also affects the type of production technology applied and customization techniques.

The scissor lift schematic design determines the material selection to ensure the scissor lift assembly’s functionality, durability, safety, and longevity.

The scissor arms are the most important part of a scissor lift in terms of material strength. These components handle the majority of the load’s weight. The preferred material for scissor pillars is steel because it can be modified to withstand heavy-duty lifting without breaking, buckling, or bending.

Each component of a scissor lift requires different materials or similar materials but in a modified form.

- Scissor arms: are the main components of a scissor lift, designed to provide maximum support without breaking, bending, or buckling; they are fabricated from sheet metal made of steel.

- Hydraulic cylinders: Hydraulic cylinders consist of piston rods, a connecting bore, a ball, and a socket joint. Only materials that can withstand maximum operating pressure from the scissor arms to prevent bursting from pressure and locking are specified. Piston rods, ball joints, and cylinders consist of hardened steel, aluminium, or cast nodular iron.

- Lift table: Material for the lift table should handle more than the specified maximum load because it supports the weight of materials and operators. Top platforms consist of hardened steel.

- Base platform: This component bears the weight of the scissor lift structure and ensures stability. The base is made of rigid steel to manoeuvre on flat surfaces and high travel in unstable environments.

- Wheels: The wheels attached to the base platform depend on whether the scissor lift handles medium-duty or heavy-duty work and whether it is specified for indoor or outdoor use. Wheels are generally fitted with solid tires to prevent punctures when in operation. The material used for manufacturing scissor lift tires is designed to be non-marking.

- Scissor linkage design: The cylinder(s) fill up with hydraulic fluid or compressed air. These become compressed, and air is pushed from one area to another. The cylinder is pushed outwards, which causes the legs to push apart. This sequence of events then raises the platform.

One of the critical specifications of a scissor lift’s functionality is its maximum elevation height. The scissor mechanism can lift to 60ft in height, although stability is a critical safety factor when operating at height. Ensure to check your local regulations that govern aerial lift dimensions to prevent workplace injuries from poorly designed lifts.

A critical factor determining scissor lift dimensions is the maximum lift capacity. Therefore, as loads get heavier, scissor lift measurements need to adjust to accommodate the extra weight and stress on components. Our engineers will work through the scissor lift design calculations depending on the scissor lifts sizes.

The dimensions of a scissor lift also depend on the power mechanism specified. Each model has specific dimensions developed by the manufacturer from years of experience designing and manufacturing specialized scissor lifts. If you need a specialized scissor lift, work with a company like Handling Speciality that has qualified engineers and years of design and manufacturing experience.

As a guideline, these are the dimensions of an electric scissor lift handling 1,200 lbs loads:

Lift capacity | 1,200 lbs |

Lifting height | 25.92 ft |

Drive | 2×4 (2 wheel-drive) |

Power source | Electric |

Approx. Scissor lift weight (Gross weight) | 4,323 lbs |

Stowed height (guard rails) | 85.83 unstowed |

Stowed width | 3.84 ft |

Stowed length | 8 ft |

Platform size | 7.41 x 3.81 ft |

Wheels | Non-marked |

Wheelbase | 73 in |

Extension deck | 3 Ft |

Extension deck lift capacity | 250 lb |

Ground clearance | 4 in |

A diesel scissor lift handling a similar capacity range of 1,250 lbs has slightly different dimensions. Remember that diesel and electric lifts differ in design due to the nature of the work they handle and their power source.

|

Lift capacity |

1,250 lbs |

|

Lifting height |

31.82 Ft |

|

Drive |

4×4 (4 wheel-drive) |

|

Power source |

Diesel |

|

Approx. scissor lift weight (Gross weight) |

11,975 Lbs |

|

Stowed height (Guardrails) |

92.5 in |

|

Stowed width |

5.68 Ft |

|

Stowed length |

8.6 Ft |

|

Platform size |

10.5 x 5.91 Ft |

|

Wheels |

Solid |

|

Wheelbase |

73 in |

|

Extension deck |

3.94 Ft |

|

Extension deck lift capacity |

300 lb |

|

Ground clearance |

8 in |

Our engineers will work with you on specialized scissor lifts and advise you on the correct dimensions required for your specifications and scissor lift sizes and weights. In addition, our engineers conduct multiple site visits to establish accurate measurements, the operating terrain, and the space available before developing your equipment solution.

All scissor lift designs must comply with industry regulations, federal and provincial safety regulations, and quality certifications. Handling Specialty is ISO certified, approved to provide professional engineering services, and CWB certified. These criteria affirm that your manufacturer develops scissor lift solutions that comply with all applicable manufacturing and safety regulations.

Handling Specialty is a leading manufacturer of scissor lifts in Canada, across the US and worldwide. Our company develops and customizes lifting systems across various industries, such as the automotive sector, aerospace, power generation, entertainment, rail transit, iron, and steel industries.

Our specialized manufacturing facility fabricates lifting solutions with varying capacities, from simple scissor lifts with 1,000 lbs capacity to heavy-duty machinery with lifting capacities of 20,000 lbs and up.

We manufacture and customize lifting equipment in the following categories:

- Mechanical Scissor Lifts

- Multi-Post Lifts & Vertical Assembly Cells

- Multi-Stage and Large Capacity Scissor Lifts

- Rail Maintenance Equipment

- Rotators

- Custom Personnel Lifts & Work Access Platforms

- Custom Theater & Underwater Stage Systems

- Hydraulic Scissor Lifts

- In-Floor Lifting Systems

- Manually & Automatically Guided Vehicles

- Lift table design

In addition to developing the equipment, we provide after-sales service, installation, and personnel training to help your employees with the machinery. We also offer spare parts and conduct regular service and repair work on your lifts. Our approach is to provide everything a client requires under one roof so that you can focus on your core business. Ready to acquire high-quality scissor lifts? Get in touch with us.