Making your workforce productive while following strict industry standards is easier with the right material handling solutions employed. Ergonomic equipment is vital to reaching these goals. Custom work positioners have become beneficial tools. They allow for precise positioning and help reduce physical strain on workers. With these smart solutions, employees can do their jobs more efficiently and safely.

Understanding Custom Work Positioners

Work positioners are lifts that help technicians in the assembly, manufacturing, and maintenance repair operation (MRO) industries. These adjustable devices let workers assemble equipment in a work cell efficiently and safely, which helps reduce strain while doing repetitive tasks. Also, custom tooling makes them more flexible for different uses. This means businesses can meet their specific needs and boost productivity significantly.

Work positioners can be customized to meet the facility’s specific needs. Companies can create solutions that fit their workflows and employee needs by working with material handling experts, like Handling Specialty. This teamwork helps ensure that work positioners work well with what is already in place. This way, they can significantly improve productivity and the well-being of workers and products.

The Role of Custom Work Positioners in Modern Industries

Custom work positioners are essential tools in many modern industries. They change how materials are assembled and significantly improve speed and efficiency. These tools, from manufacturing and assembly to welding and fabrication, help make the workplace safer and more efficient.

Handling Specialty is a leader in ergonomic solutions for heavy-duty, custom personnel lifts and work positioners. It knows how vital it is to provide special equipment for different industries. Their custom work positioners are made to fit specific weight limits, sizes of items, and work needs to ensure that they perform well and make workers comfortable in any setting.

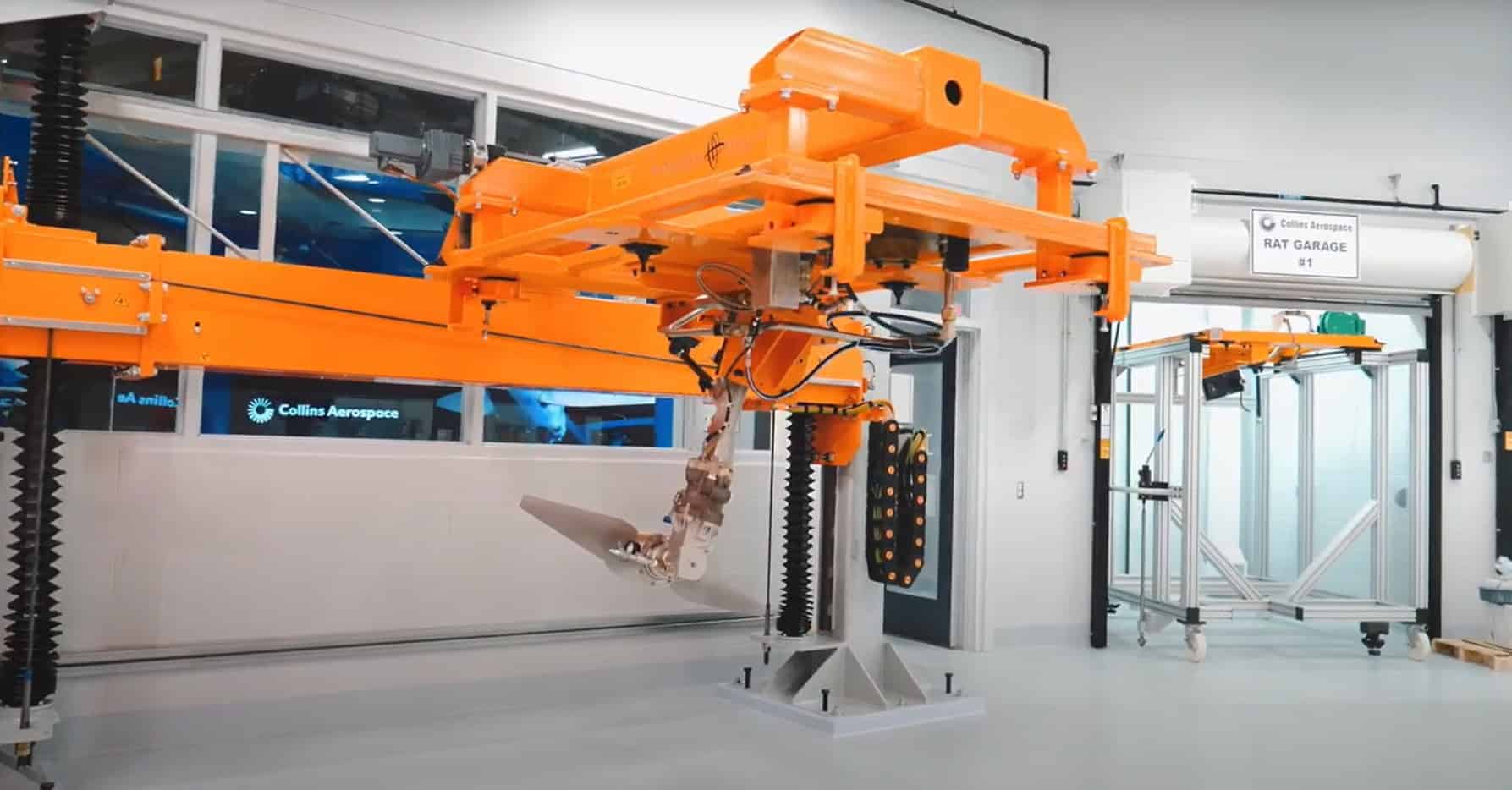

By helping with material handling tasks or even automating them, custom positioners lessen the need for manual labor, and lowers the chances of injuries and human errors. As a result, companies see higher productivity and less downtime, leading to better workflow, more profits, and a stronger position in today’s fast-moving industrial world.

Types of Custom Work Positioners and Their Applications

Custom work positioners have different designs for various needs. Lift tables are suitable for raising and lowering heavy items. They work well for tasks like assembly and moving materials. These tables can change height and have different platform sizes to fit different loads and spaces.

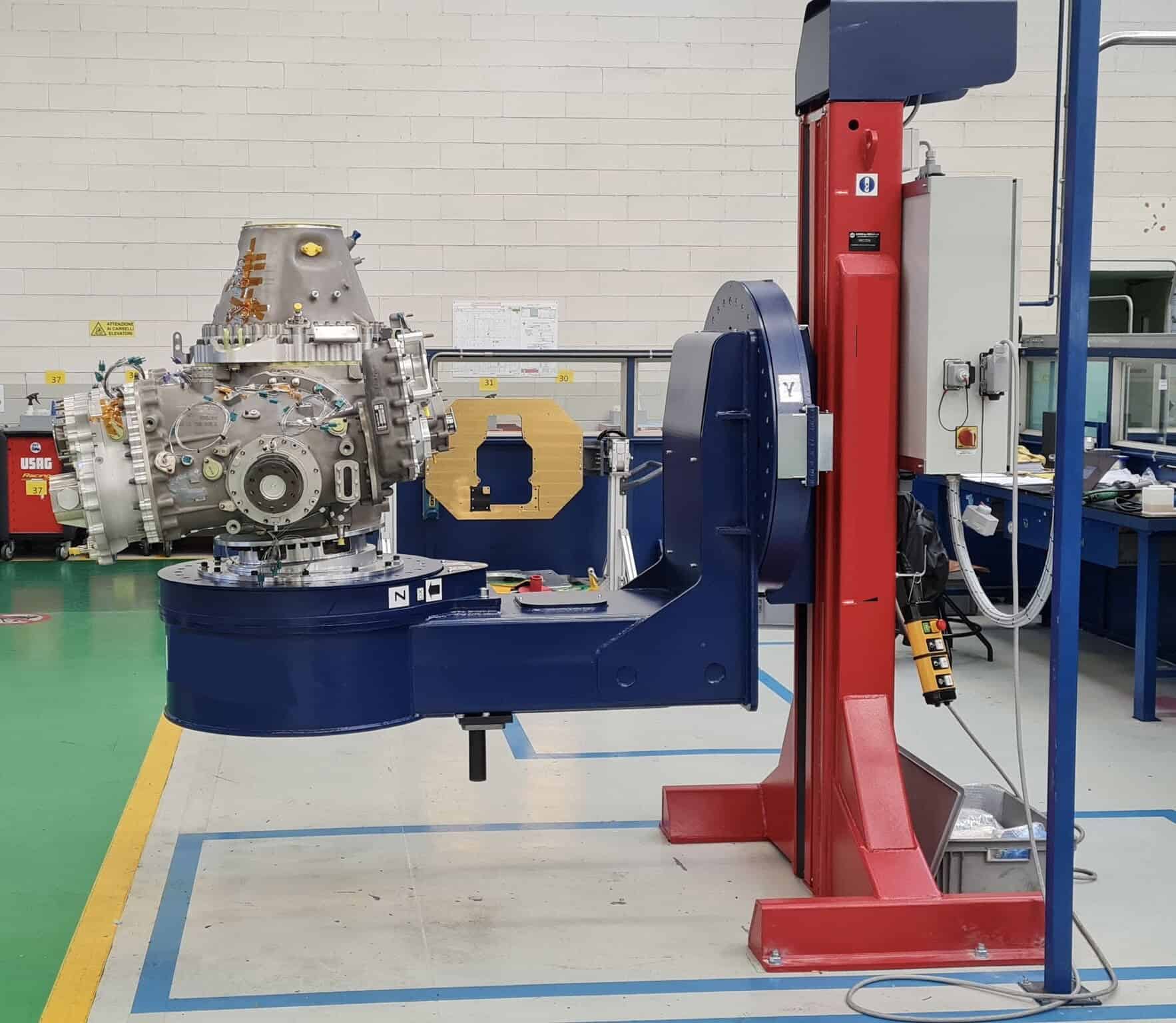

Headstock / Tailstock, custom work positioners, rotate the product 360 degrees to precisely position the equipment for weldments, wiring, and other assembly tasks.

Scissor lifts are flexible in size and capacity, perfect for moving equipment up and down. Their criss-cross support legs let them reach great heights without taking up much space. Scissor lifts suit tasks such as maintenance, installation, and assembly. They can also be fitted with additional tooling like turn tables, roller tables, and other specific tools for the individual task.

Special custom positioners are used for tasks that require great accuracy. They help operators move items precisely, which is essential for detailed assembly, welding tasks, and quality checks.

The Ergonomic Benefits of Custom Work Positioners

Custom work positioners are designed to support good posture, lessening welder fatigue. They help workers stay in a neutral position, which means less bending, twisting, or reaching. This reduction in movement helps lower the chance of musculoskeletal disorders (MSDs).

When a company invests in these custom tools, it demonstrates that it cares about the safety and well-being of its employees. This approach creates a better workplace and helps keep workers healthy over the long term. By solving ergonomic issues, companies can reduce workplace injuries and healthcare costs and increase overall productivity.

Enhancing Worker Comfort and Ergonomic Safety

Custom work positioners are very important for workers’ comfort and safety. They precisely position equipment for ease of welding or other production tasks. It lowers physical strain and fatigue, meaning workers do not have to reach, bend, or lift heavy things.

Worker safety is improved because there is less need for manual labor when lifting, holding, or moving heavy items. This helps create a safer workplace by lowering the chance of accidents or injuries that come from improperly handling of products.

Additionally, custom positioners provide adjustable height, tilt functions, and rotating platforms. This allows workers to change their work areas to fit their needs and preferences, increasing comfort and helping avoid strain or pain.

Custom Work Positioners and Employee Productivity

The connection between custom work positioners and employee productivity is evident. Workers who are comfortable and can work well feel less physical strain and fatigue. This boost in comfort helps them be more productive. Better ergonomics means they are more focused, finish tasks quicker, and increase product throughput.

Also, less discomfort and good posture during the day make workers happier and healthier. When a company shows it cares about its employees’ well-being, it creates a positive workplace. This helps raise morale and makes people feel valued.

How Custom Work Positioners Lead to Efficient Work Processes

Custom work positioners are pivotal in streamlining workflows and promoting efficient work processes. These solutions minimize wasted movement and optimize task flow by optimizing material handling and providing easy access to product during assembly, MRO, and manufacturing. Operations involving assembly, inspection, or intricate manipulations benefit significantly from the precision and stability these work positioners offer.

Data collection and analysis further contribute to process optimization. By integrating sensors and software, manufacturers can gather valuable insights into cycle times, operator movements, and ergonomics. These data-driven insights empower informed decision-making to fine-tune processes, identify bottlenecks, and implement targeted improvements.

|

Feature |

Benefit |

Impact on Efficiency |

|

Adjustable Height |

Reduced Strain, Improved Accessibility |

Faster task completion, Reduced fatigue |

|

Tilt and Rotation |

Optimal Viewing Angles |

Enhanced precision, Reduced errors |

|

Custom Tooling |

Task-Specific Functionality |

Streamlined workflow, Increased throughput |

|

Data Integration |

Performance Monitoring, Ergonomic Analysis |

Data-driven optimization, Continuous improvement |

Case Studies: The Positive Impact on Productivity Levels

Many case studies show the real benefits of using custom work positioners. For example:

- Heavy Welding Industry

- Robotic Welding, cutting and Assembly

- Production Welding

- Laser Applications [Welding, Cutting]

- Component Assembly

- Cleaning

Conclusion

Custom work positioners are crucial for making employees more productive and happy in today’s workplaces. They help reduce musculoskeletal disorders and improve comfort, work processes, and productivity. Handling Specialty has multiple case studies showing how these tools have assisted overall performance in assembly, MRO, and manufacturing processes. Custom work positioners create a safer and more efficient work environment for employees, increasing productivity and satisfaction.

Frequently Asked Questions

What are the primary benefits of using custom work positioners?

Custom work positioners have many benefits. They improve worker safety. They help workers finish their tasks faster and easier, boosting productivity. These positioners are very versatile, making them useful for different tasks. They also provide great ergonomic benefits that support employee well-being.

How do custom work positioners affect employee health and safety?

Custom work positioners help employees stay healthy and safe by encouraging good posture while reducing strain. This helps lower the chance of musculoskeletal disorders. These ergonomic tools also assist companies in following safety requirements. They create a healthier work atmosphere.

Can custom work positioners be integrated into any industry?

Custom work positioners can fit into many industries with the right design and custom tooling. They help meet specific needs. These positioners can support a diverse workforce or improve different tasks. They provide flexible solutions that adapt to what you need.