Hydraulic scissor lifts and tables are durable and equipped with a range of safety features and mechanisms. These include emergency stop buttons, limit switches, and overload relays, all designed to ensure the safe operation of these machines. These mechanisms are a testament to the reliability of hydraulic scissor lifts and tables, making them a trusted choice for industrial applications.

Understanding Hydraulic Scissor Lifts & Tables

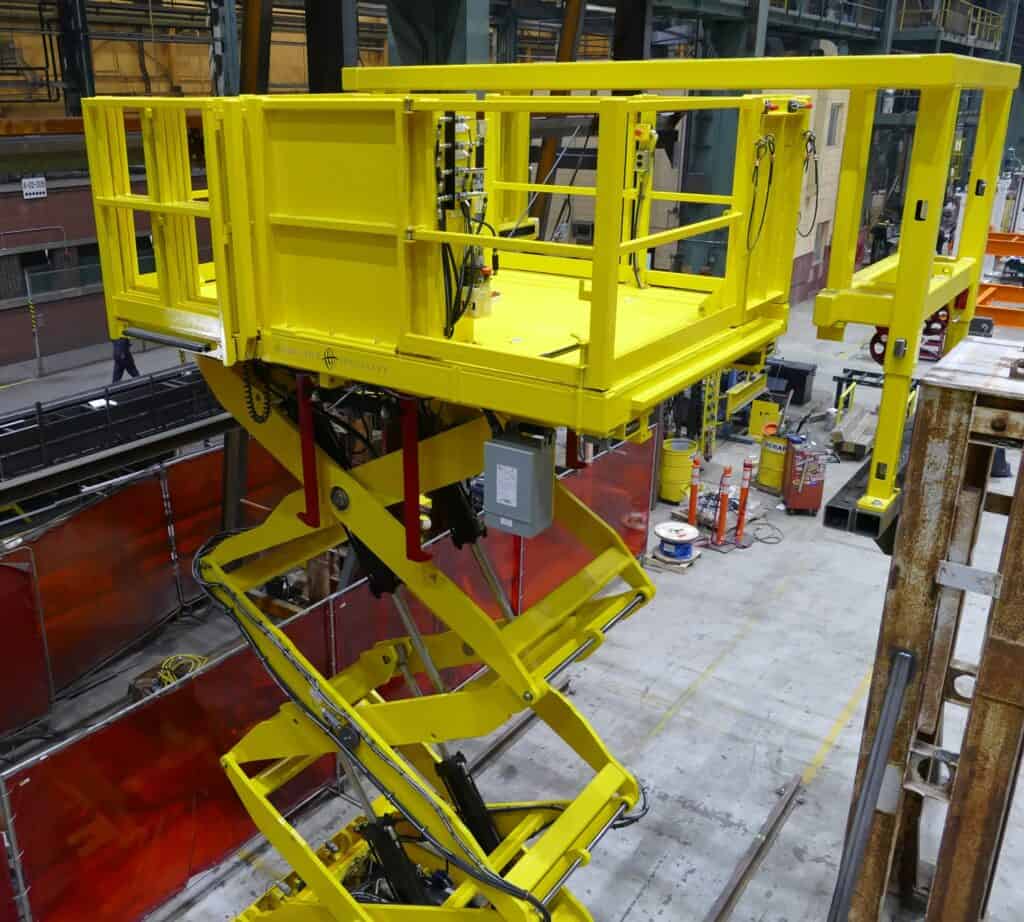

Hydraulic scissor lifts and tables are lifting equipment that uses hydraulic power to raise and lower heavy loads. The hydraulic scissor lift table is a versatile machine that can be utilized in various custom applications requiring efficient lifting and handling. These devices are commonly used in maintenance repair operations (MRO), manufacturing facilities, assembly processes, and other industrial settings.

The basic principle behind hydraulic scissor lifts and tables is the use of hydraulic cylinders to provide the lifting force. A hydraulic cylinder is a mechanical actuator that converts hydraulic power into linear motion. When hydraulic fluid is pumped into the cylinder, it pushes against a piston, which, in turn, moves the scissor legs of the lift table. This upward motion raises the platform, allowing for the lifting and handling of heavy objects.

Hydraulic scissor lifts and tables are designed to provide a stable and secure platform for lifting and handling operations. The scissor legs of the lift table, which extend and retract to adjust the platform height, play a crucial role in maintaining the platform’s level and balanced position during movement. This design feature allows for the safe and efficient handling of heavy loads without the risk of tipping or instability.

These lifts and tables can be operated using various control mechanisms, such as push buttons or levers. Some models also offer additional features, such as adjustable height settings and tilt functions, to provide extra versatility and convenience. For instance, a scissor lift system with pre-programmed lift heights can be added for assembly processes, allowing for automated and precise lifting operations.

Overall, hydraulic scissor lifts and tables are essential tools for lifting and handling heavy loads in industrial settings. Their hydraulic power and sturdy construction make them reliable and efficient equipment for a wide range of applications. Understanding the importance of proper selection based on load capacity and platform size empowers businesses to make informed decisions about their lifting equipment needs.

How Hydraulic Scissor Lifts Compare to Other Types

Hydraulic scissor lifts are popular for lifting and handling heavy loads in industrial settings, but they are not the only type available. Other types, such as pneumatic lift tables, offer alternative solutions to oil hydraulics for specific applications. However, hydraulic scissor lifts stand out for their ability to handle heavier loads and their versatility in various industrial settings.

Pneumatic lift tables use compressed air rather than oil to generate the lifting force. They are often used in applications requiring precise control and quick response time. Pneumatic lifts can be operated with the same controls as oil hydraulic scissor lifts, providing smooth and quiet operation.

Key Features of High-Quality Hydraulic Scissor Lifts

High-quality hydraulic scissor lifts have several key features that make them reliable and efficient equipment for safely lifting and handling heavy loads. Durability is one of the essential features of these lifts. They are constructed using materials like heavy-duty steel and quality components to ensure long-lasting performance in demanding industrial environments.

Safety mechanisms are another crucial aspect of high-quality hydraulic scissor lifts. These lifts are equipped with emergency stop buttons, limit switches, and overload relays to prevent accidents and ensure safe operation. These safety features provide operators peace of mind and help maintain a safe working environment.

Durability and Construction Material

Durability is a critical factor to consider when choosing hydraulic scissor lifts. These lifts are subjected to heavy loads and rigorous working conditions and must be constructed using high-quality materials.

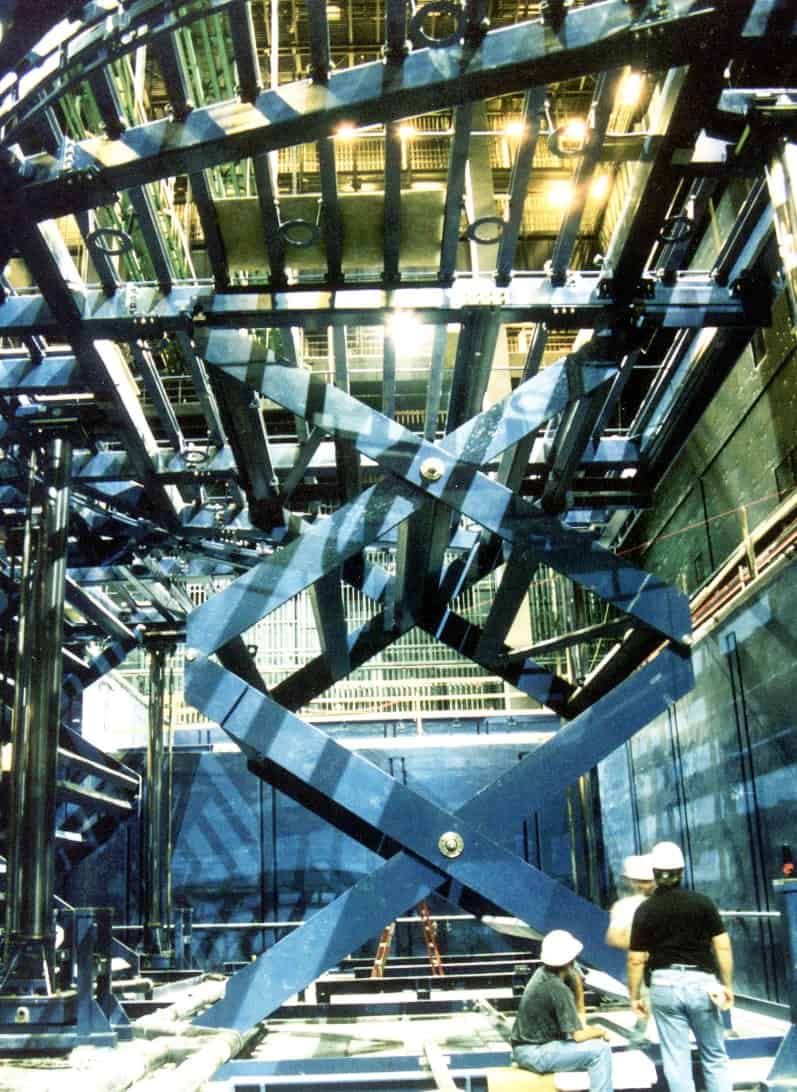

Stainless steel offers excellent corrosion resistance and is suitable for applications where hygiene or cross-contamination is a concern, such as the food and pharmaceutical industries. It is also durable and can withstand the wear and tear associated with underwater material handling operations, such as theaters designed to include water shows like Cirque Du Soleil’s “O” show in Las Vegas.

In addition to stainless steel, other high-quality construction materials, such as hardened steel and reinforced components, are used to ensure the durability of hydraulic scissor lifts. These materials provide the necessary strength and resilience to withstand heavy loads and maintain the lift’s performance over time.

By investing in high-quality hydraulic scissor lifts with durable construction materials, businesses can ensure long-term reliability and minimize maintenance and replacement costs.

Safety Features and Mechanisms

Safety is of utmost importance when it comes to hydraulic scissor lifts, especially in industrial settings where operators and workers rely on these lifts to perform their tasks safely. High-quality hydraulic scissor lifts from Handling Specialty are equipped with various safety features and mechanisms to ensure safe operation.

Emergency stop buttons are one of the key safety features of hydraulic scissor lifts. These buttons allow operators to quickly stop the lift in case of an emergency or potential hazard. Limit switches are also commonly used to automatically halt the platform when it reaches its designated height, preventing the lift from exceeding its safe operating limits.

Overload relays are another crucial safety mechanism in hydraulic scissor lifts. These relays monitor the load on the lift and prevent the motor from burning out by cutting off the power if the load exceeds the lift’s capacity. Note: It is never recommended that the lift’s capacity ratings be exceeded.

Additionally, safety clearance between the scissor legs helps prevent trapping hazards. Self-lubricating bushings in pivot points reduce maintenance requirements and ensure smooth and reliable operation. These safety features and mechanisms provide operators with peace of mind and contribute to a safer working environment.

Bellows are another safety feature that can help prevent feet or hands from entering the scissors as they travel up and down while in application.

Load Capacity and Platform Size

Load capacity and platform size are important considerations when selecting hydraulic scissor lifts. The load capacity refers to the maximum weight the lift can safely handle, while the platform size determines the available working area.

Here are some key points to consider:

- High-quality hydraulic scissor lifts offer load capacities ranging from a few hundred pounds to several tons.

- The load capacity should be chosen based on the application’s specific requirements, ensuring that the lift can safely handle the intended loads.

- The platform size should be sufficient to accommodate the size and shape of the lifted or transported objects.

- Larger platform sizes provide more working area and flexibility for handling larger loads or multiple objects.

- When selecting the platform size, it is important to consider the available space in the work area and any restrictions or limitations.

- It is also necessary to consider what custom tooling might be included on the platform for your specific application needs.

Businesses can optimize their lifting and handling operations by choosing hydraulic scissor lifts with the right load capacity and platform size, ensuring safe and efficient load handling.

Types of Hydraulic Scissor Lifts & Tables

Different types of hydraulic scissor lifts and tables are available to cater to various applications and requirements. These types include portable lift tables, heavy-duty lifts, and compact lift tables.

Portable lift tables offer the flexibility of easy transportation and can be used in different locations within a facility. They are often equipped with wheels or casters for mobility.

Heavy-duty lifts are designed to handle extremely heavy loads and are commonly used in construction, manufacturing, and mining industries.

Compact lift tables are ideal for applications with limited space, as they have a smaller footprint and can fit into tight areas.

Heavy-Duty Lifts for Industrial Use

Heavy-duty hydraulic scissor lifts are specifically designed to handle extremely heavy loads in demanding industrial environments. These lifts offer robust construction, enhanced load capacities, and additional features to ensure safe and efficient lifting operations.

Here are some specifications of heavy-duty hydraulic scissor lifts:

| Load Capacity | Vertical Travel | Platform Size |

| 10,000 lbs and above | Up to 20 feet | Customizable |

- Heavy-duty hydraulic scissor lifts can handle load capacities of 10,000 lbs and above, making them suitable for lifting heavy machinery, equipment, or materials such as steel blanks.

- They offer vertical travel of up to 20 feet, providing the necessary height for various industrial applications.

- The platform size of heavy-duty lifts can be customized to accommodate large loads or multiple objects.

Heavy-duty hydraulic scissor lifts are commonly used in the manufacturing, construction, mining, and heavy equipment maintenance industries. They provide the strength, stability, and durability required for demanding industrial use.

Choosing the Right Hydraulic Scissor Lift

Choosing the right hydraulic scissor lift involves considering several factors, including your specific needs, space requirements, and budget. Here are some points to guide you in the selection process:

- Assess your needs: Determine the load capacity, custom tooling, vertical travel, and platform size required for your application.

- Consider space requirements: Evaluate the available space in your facility and choose a lift that fits within the given dimensions.

- Set a budget: Determine the budget for your hydraulic scissor lift and explore options that offer the best value for money.

By considering these factors and selecting a lift that meets your requirements, you can ensure optimal performance, safety, and efficiency in your lifting operations.

Assessing Your Needs and Space Requirements

Assessing your needs and space requirements is crucial when choosing a hydraulic scissor lift. Here are some points to consider:

- Variety of applications: Identify the different applications for which you will be using the lift. Determine the load capacity, custom tooling, vertical travel, and platform size needed for each application.

- Space requirements: Measure the available space in your facility, including height restrictions and floor space. Consider any obstructions or obstacles that may impact the installation and operation of the lift.

- Industry-specific requirements: If you work in a specialized industry, such as aerospace, ensure that the lift meets your industry’s specific requirements and regulations.

By thoroughly assessing your needs and space requirements, you can choose a hydraulic scissor lift tailored to your applications and offering optimal performance and efficiency. Your initial research should include choosing an experienced design/build firm to create your scissor lift who will visit your site and provide a free consultation.

Considering Load Capacity and Elevation Height

When choosing a hydraulic scissor lift, consider the load capacity and elevation height required for your specific application. The load capacity refers to the maximum weight that the lift can safely handle. It is crucial to determine the weight of the objects or materials that will be lifted to ensure that the lift can handle the load without any issues.

Vertical travel or elevation height is another important factor to consider. It refers to the distance the lift can travel from its lowest to its highest position. This is particularly important if you need to lift objects to specific heights or if your facility has limited overhead clearance.

By understanding your application’s load capacity and elevation height requirements, you can choose a hydraulic scissor lift that meets your specific needs. Selecting a lift with a load capacity higher than your maximum load is important to ensure safe and efficient operation. Additionally, consider the available vertical travel options to ensure the lift can reach the desired height for your tasks.

Budget and Maintenance Considerations

Consider your budget and long-term maintenance requirements when purchasing a hydraulic scissor lift. Hydraulic scissor lifts come in a wide range of prices, depending on their customized specifications and features. Determining your budget and finding a lift that fits your financial constraints without compromising on quality and safety is essential.

In addition to the initial purchase cost, it is also important to consider the lift’s maintenance requirements. Regular maintenance is crucial to ensure the lift’s smooth and safe operation. Routine checks, such as inspecting hydraulic hoses and cylinders, lubricating moving parts, and checking for any signs of wear and tear, should be performed to prevent potential issues. Your scissor lift OEM should offer you a Planned Maintenance Program to follow.

Another factor to consider is the lift’s lowered height. The lowered height refers to the height of the lift when it is in its lowest position. This is particularly important if you have height restrictions in your facility. Choosing a lift with a lowered height that meets your requirements can help you optimize space utilization and ensure easy access to the lift. Any scissor lift can be recessed into the plant floor if required.

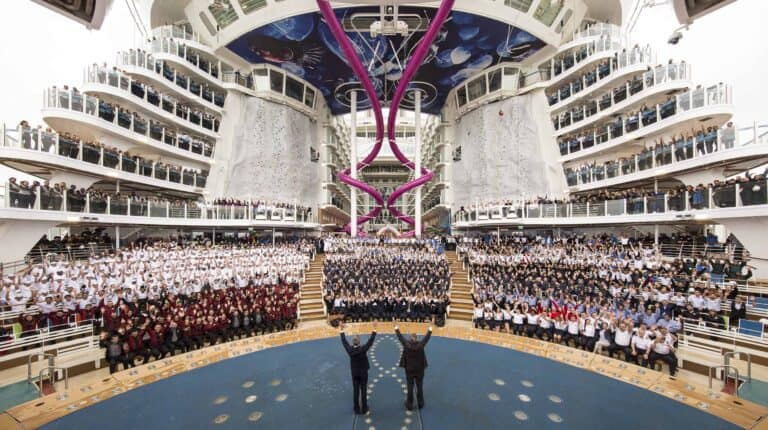

Applications of Hydraulic Scissor Lifts in Various Industries

Hydraulic scissor lifts have a wide range of applications in various industries. They are commonly used in manufacturing and MRO facilities for material handling tasks. These lifts provide a stable and efficient platform for loading and unloading heavy objects, improving productivity and worker safety.

In manufacturing, hydraulic scissor lifts are used for assembly line work, positioning materials, personnel, and equipment, and transporting goods between different production areas. They can also be used in warehouse operations for pallet handling, inventory management, and order picking.

Hydraulic scissor lifts’ versatility and flexibility make them ideal for a variety of applications, helping businesses in different industries improve efficiency and streamline their operations.

Automotive and Aerospace Applications

Hydraulic scissor lifts are crucial for handling heavy components and equipment in the automotive and aerospace industries. In the automotive sector, these lifts are commonly used in automotive assembly lines, where they provide a stable and secure platform for performing assembly, maintenance, and inspections. Scissor lifts can also be affixed to AGV platforms to alter the height of the car or plane part as it goes through the assembly process.

In the aerospace industry, hydraulic scissor lifts are used for handling aircraft components, engines, and other heavy equipment. They provide a safe and efficient solution for lifting and positioning these components during assembly, maintenance, testing, and repair processes. These lifts are designed to meet the specific requirements of the aerospace industry, ensuring the safety and precision required for aircraft maintenance, testing, and manufacturing.

Businesses can improve productivity, worker safety, and overall operational efficiency by utilizing hydraulic scissor lifts in the automotive and aerospace industries.

Routine Maintenance Checks and Tips

Routine maintenance checks are crucial for ensuring hydraulic scissor lifts’ smooth and safe operation. Here are some tips for performing routine maintenance checks:

- Inspect Hydraulic Hoses and Cylinders: Regularly inspect hydraulic hoses and cylinders for any signs of wear, damage, or leaks. Replace any damaged components immediately to prevent any potential issues.

- Lubricate Moving Parts: Regularly lubricate the lift’s moving parts to ensure smooth operation and prevent premature wear. Use lubricants recommended by the manufacturer for optimal performance.

- Check for Signs of Wear and Tear: Inspect all lift components for signs of wear and tear, such as worn-out seals or bearings. Replace any worn-out components to ensure safe and efficient operation.

- Ensure Functionality of Safety Features: Regularly check the functionality of safety features such as limit switches, emergency stop buttons, and overload relays. Test these features to ensure they are working properly and can effectively prevent accidents or damage.

By following these routine maintenance checks and tips, businesses can extend the lifespan of their hydraulic scissor lifts and ensure their safe and efficient operation. Additionally, with IIoT (Industrial Internet of Things), a scissor lift can include sensors that monitor wear and tear on components and alert the OEM before the unit is damaged.

Hydraulic scissor lifts and tables offer unmatched efficiency and safety in various industries. Understanding their technology, features, and types is crucial in choosing the right one for your needs. From durability to load capacity, these lifts are built for heavy-duty industrial use or compact designs for specific applications. Maintenance tips and professional installation ensure optimal performance and longevity. Whether in manufacturing, automotive, or MRO operations, hydraulic scissor lifts play a vital role in enhancing productivity and safety standards. Knowing how to troubleshoot common issues and exploring customization options further enhances their versatility. Elevate your operations with high-quality hydraulic scissor lifts tailored to your requirements.

Frequently Asked Questions

What is the Average Lifespan of a Hydraulic Scissor Lift?

The average lifespan of a hydraulic scissor lift depends on various factors, such as maintenance, usage, and the specific model. With proper maintenance and regular checks, hydraulic scissor lifts can last for decades. However, it is essential to follow the manufacturer’s recommendations for maintenance and ensure that the lift is used within its specified load capacity and operating parameters.

Can Hydraulic Scissor Lifts Be Customized for Specific Needs?

Yes, hydraulic scissor lifts can be customized to meet specific needs. They can be equipped with various accessories, custom tooling, and features to enhance their functionality and efficiency. Additionally, they can be configured to meet specific load capacities, platform sizes, and height requirements. Some models also offer adjustable features to accommodate different tasks and working conditions.

How Do I Troubleshoot Common Hydraulic Scissor Lift Issues?

Troubleshooting common hydraulic scissor lift issues involves identifying the problem and taking appropriate steps to resolve it. Some common issues include hydraulic leaks, malfunctioning cylinders, and hoist problems. It is important to refer to the manufacturer’s troubleshooting guide or consult a professional for specific guidance on resolving these issues.