Overview

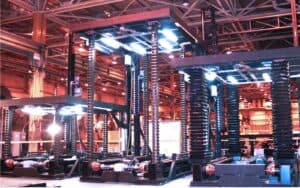

Handling Specialty custom engineered and manufactured a set of three rigid chains actuated stage lifts for one of the newest stage productions in Las Vegas. These stage lifts were installed underneath the main stage area and are used to move sets, scenery, props and performers on and off the stage. The lifts are extremely responsive and quiet, which is necessary for a show of this calibre. The lifts are programmed into the show’s central controls and perform the same set of movements for the show twice a day, five days a week. During a Factory Acceptance Test in Hamilton, Ontario, Handling Specialty’s lift system was connected to the front-end show control network and was operational immediately.

Features

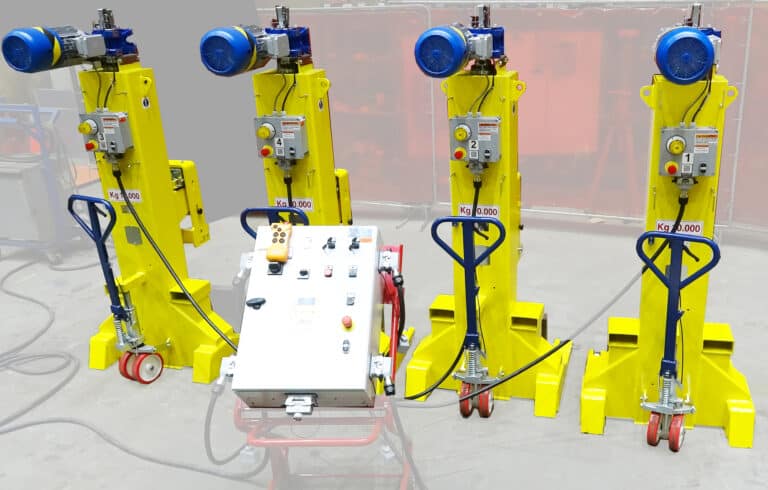

- Capacity 10,400 lbs dynamic, 31,200 static (on each of three lift platforms), rigid chain actuation (four on each lift), vertical travel 250”, travel rate 60 fpm.

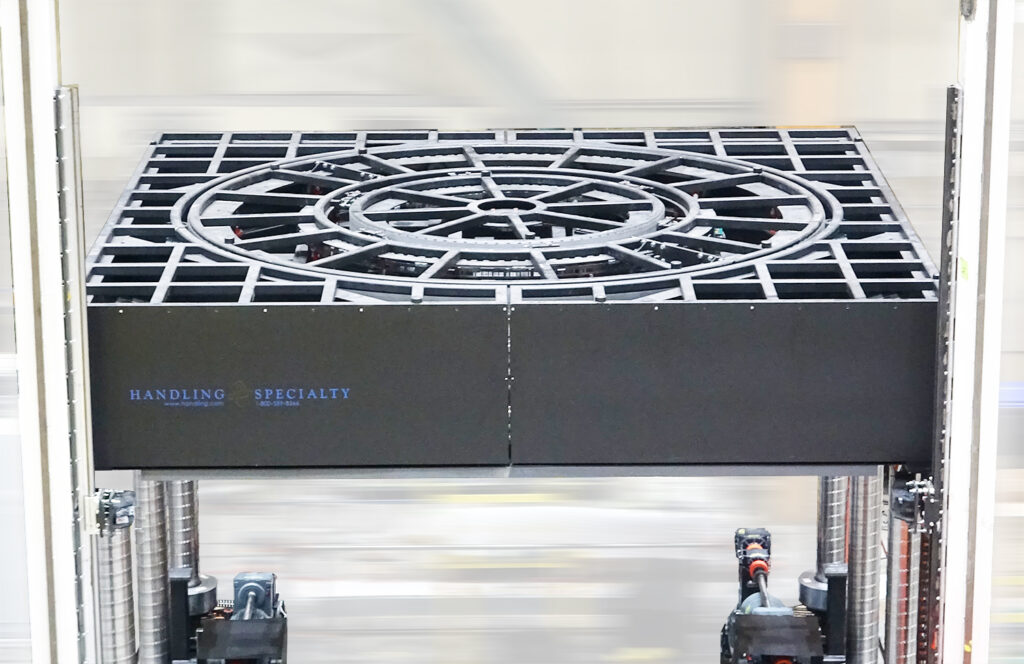

- Three stage platforms measuring 20’ x 13’ each (total 260 sq. ft. each).

- The lift actuation method ensures repeatability, precision positioning, and indexing. The actuator is a chain and pinion drive that forms an articulated telescoping member to transmit traction and thrust.

- Shear zone sensors are installed on the edges of platforms to ensure the safety of performers, technicians, and equipment.

- Lift actuators housed inside acoustic enclosures to reduce emitted noise.