Overhead Belt Lift for Material Handling

Overview These four overhead belt lifts will perform 3 cycles per hour, 24 hours per day, 300 days per year, and be used in a shuttle application at the assembly site, attached to the existing overhead conveyor structure that will raise and lower trailers during the painting process. These lifts raise and lower to precise […]

Overhead Belt Lift for Material Handling

Overview Working 48 cycles/hour, 16 hours/day, 280 days/year, these 12 electro-mechanical overhead belt lifts were designed to be integrated into an automotive manufacturer’s overhead conveyor system to move car and truck bodies through the assembly line. This belt lifts lower around the vehicle body, and custom tooling secures the underside, then the belt lifts raise […]

Mast Style Belt Lift

Overview These four custom-engineered belt lifts will be used to transfer chassis and pallets in an automated assembly line for the automotive industry. Features Designed with redundant safety systems and multiple belts, this vertical drop lifter was engineered to reduce deflection, ensure the level and accurate positioning, support cantilevered loads of up to 3,800 lbs, […]

Inverted Belt Lift for Automotive Assembly Process

Overview Handling Specialty custom engineered and manufactured a series of inverted belt lifts for a major North American automotive company. The lifts were mounted to a ceiling track and used to lift car bodies up and down (from ceiling to floor level), where they were worked on by employees. Features Rise rate 35 FPM approximate […]

Aerospace paint booth gantry system

Overview Custom-designed and built to position technicians inside a paint booth, this paint booth gantry system comes as a pair of units. Each carriage ergonomically and safely positions technicians around the aircraft parts. Lift capacity per carriage is 1000 lbs and can travel horizontally, vertically and extend outward for precise positioning. Safety is built into […]

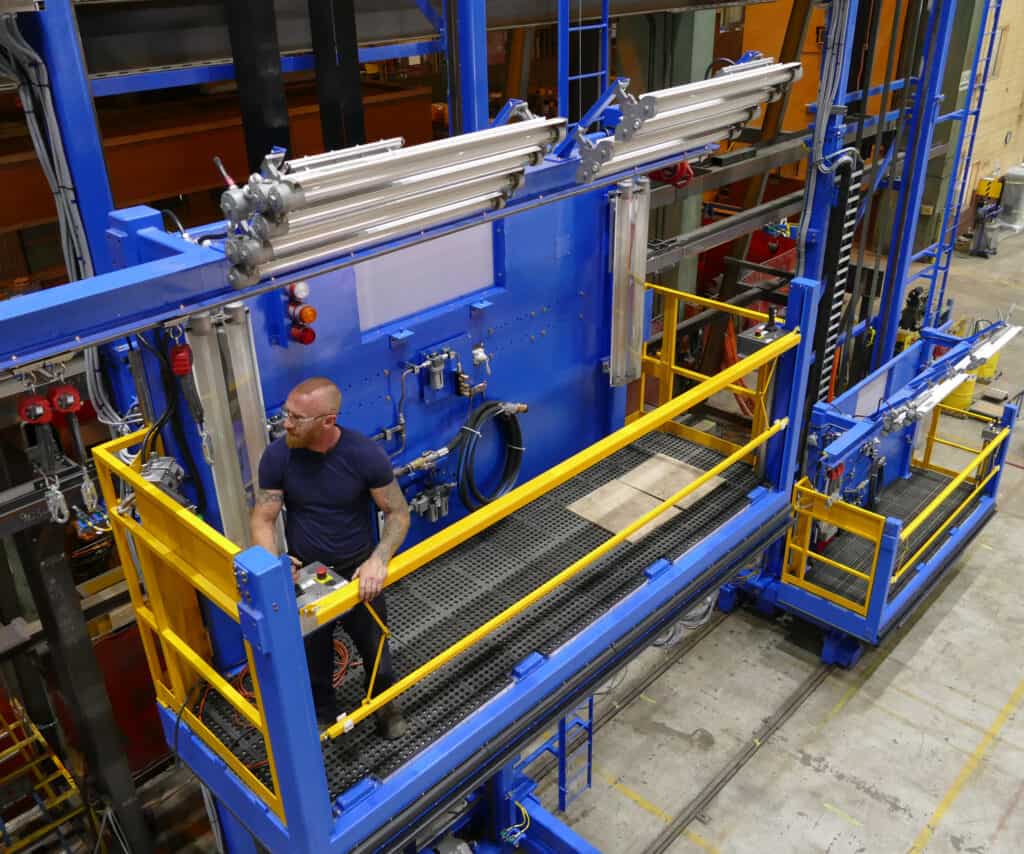

Explosion Proof Paint Booth Lifts for Aerospace Industry

Overview Handling Specialty was approached by an international aerospace company to custom engineer and manufacture multi-axis paint booth gantries for three paint booths. The gantries are designed to hold two paint technicians and paint equipment, are were custom engineered and manufactured to be safe, reliable, efficient, ergonomic and highly manouverable in an aerospace industry paint […]