Custom Lighting Lifts for Theme Park

Overview Handling Specialty custom engineered and manufactured a set of two lighting scissor lifts for a popular theme park. Designed to operate intermittently 12 times per day, the scissor lifts are lagged to the purchaser’s floor and will lift the lighting equipment 25 feet. Features Pendent controller connected to motor starter panel complete with up, […]

Aerospace Personnel Lift for Assembly

Overview These 2 custom personnel lifts, lag bolted to the shop floor, were exclusively designed for our client’s specific aerospace assembly requirements. They have a duty cycle of up/down twice every 10 minutes, 20 hours per day, 260 days per year. Features Up/down travel limit switches Velocity fuses Safety lock-up bars Controls mounted on the […]

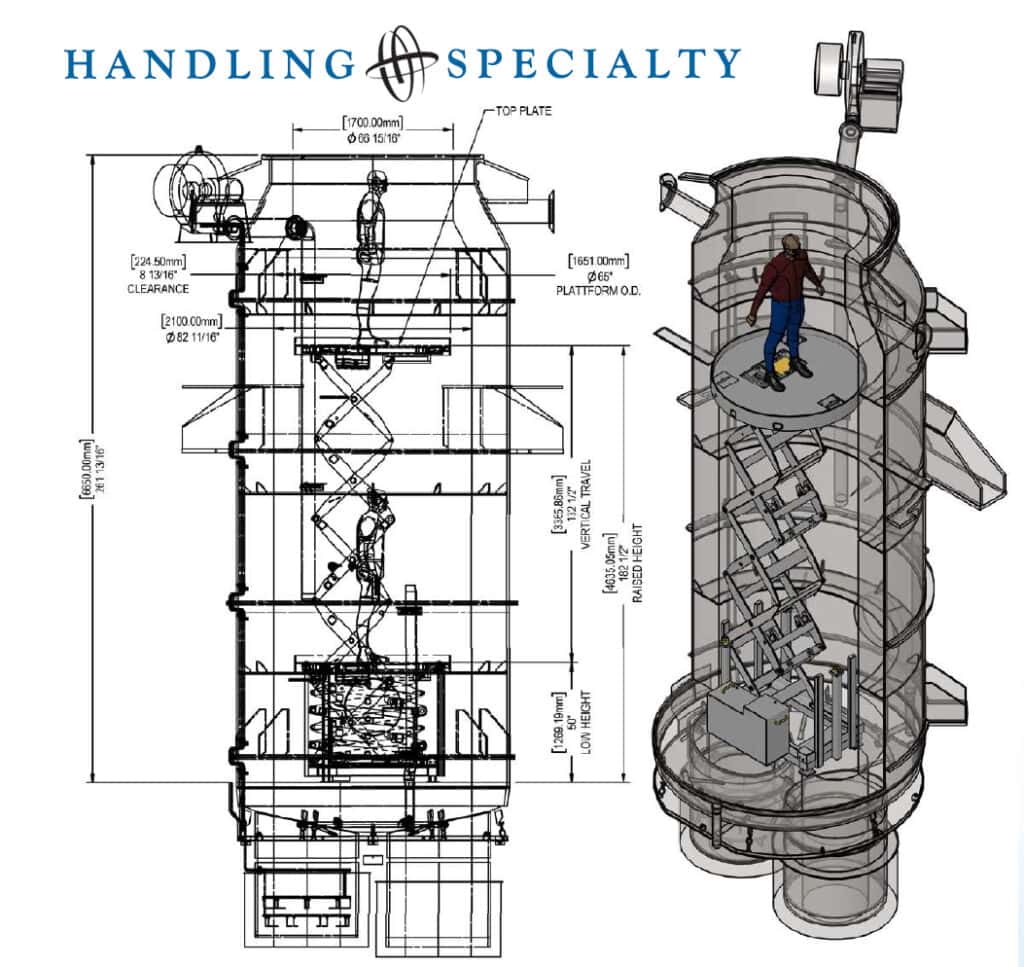

Refractory RH Degasser Multi Stage Lift

Overview This freestanding, electro-hydraulic, multi-stage, portable design was developed to fit an RH Degasser. Once the lift is lowered into, and sits on the base of the degasser, it provides a safe and ergonomic option for rebricking processes. An RH Degasser removes dissolved gases such as hydrogen present in molten steel to enable the production […]

Industrial Personnel Lift with Tilt Action

Overview This industrial personnel lift with tilt/upender component acts as a vertical assembly station to assemble large industrial fuel cells in the Energy industry. This is a custom design/build material handling solution for a new model of large scale fuel cells developed to vertically stack the components. Personnel Lift Features Lowered Height: 68″; Vertical Travel: […]

25 Ton Drop Table and Traction Motor Dolly

Overview Our rail equipment dealer received a purchase order for one 25-ton Drop Table including a traction motor dolly, locking bar pockets, packaging and freight, installation, commissioning, and training. This Drop Table system will be used to remove and re-install wheelsets on freight cars. Drop Table: The main drop table trolly uses an HPU to […]

Carrier Assembly with Hydraulic Lift

Overview The Carrier Assembly with Hydraulic Scissor Lift was designed specifically for our client. It is mounted to an overhead tugger arm and pulled through the assembly process, running intermittent operations – 35 cycles per day. The integrated scissor lift allows for precise positioning of the product at technician’s height. Features Scissor lift assembly