Choosing the right Automated Guided Vehicle Manufacturer (AGV) manufacturer for your specific application needs is an essential part of the custom AGV building experience. AGVs have become indispensable assets in modern logistics and manufacturing operations, streamlining processes and enhancing efficiency. However, with a plethora of manufacturers vying for attention, discerning the optimal partner requires a comprehensive approach. This article delves into key considerations for choosing the right AGV manufacturer, ensuring seamless integration and maximum return on investment.

Understanding Your Needs

Before embarking on the journey of selecting an AGV manufacturer, it’s imperative to conduct a thorough assessment of operational requirements. This involves defining operational goals such as improving throughput, minimizing errors, and enhancing safety. Simultaneously, identifying operational constraints, whether they are space limitations, environmental factors, or specific industry regulations, is crucial. A clear understanding of these factors lays the foundation for aligning custom, industrial AGV capabilities with organizational needs.

An AGV manufacturer’s experience serves as a testament to their proficiency in developing reliable, custom solutions. Assessing the manufacturer’s track record, including their tenure in the industry and portfolio of completed projects, provides valuable insights into their expertise. Equally significant is their reputation within the assembly and manufacturing industry, which can be gauged through testimonials, case studies, and industry recognition. A manufacturer with a proven track record instills confidence in their ability to deliver.

Evaluating Manufacturer Expertise

Client feedback serves as a confirmation of an AGV manufacturer’s performance. Seeking out testimonials and references from existing clients offers firsthand accounts of their experiences. This feedback can shed light on various aspects, including product quality, reliability, customization, and after-sales support. Additionally, engaging in conversations with current users can provide invaluable insights into the practicalities of working with a particular manufacturer.

AGV Technology and Innovation

The technological prowess of an AGV manufacturer directly influences the performance and adaptability of their solutions. Evaluating their technological capabilities involves scrutinizing the sophistication of their navigation systems, integration with existing infrastructure, customization, and compatibility with emerging technologies such as IIoT and AI. Furthermore, emphasis on innovation is vital to future-proofing AGVs against technological obsolescence. A manufacturer committed to continuous improvement and staying ahead of the curve ensures longevity and relevance of their solutions.

Quality and Reliability

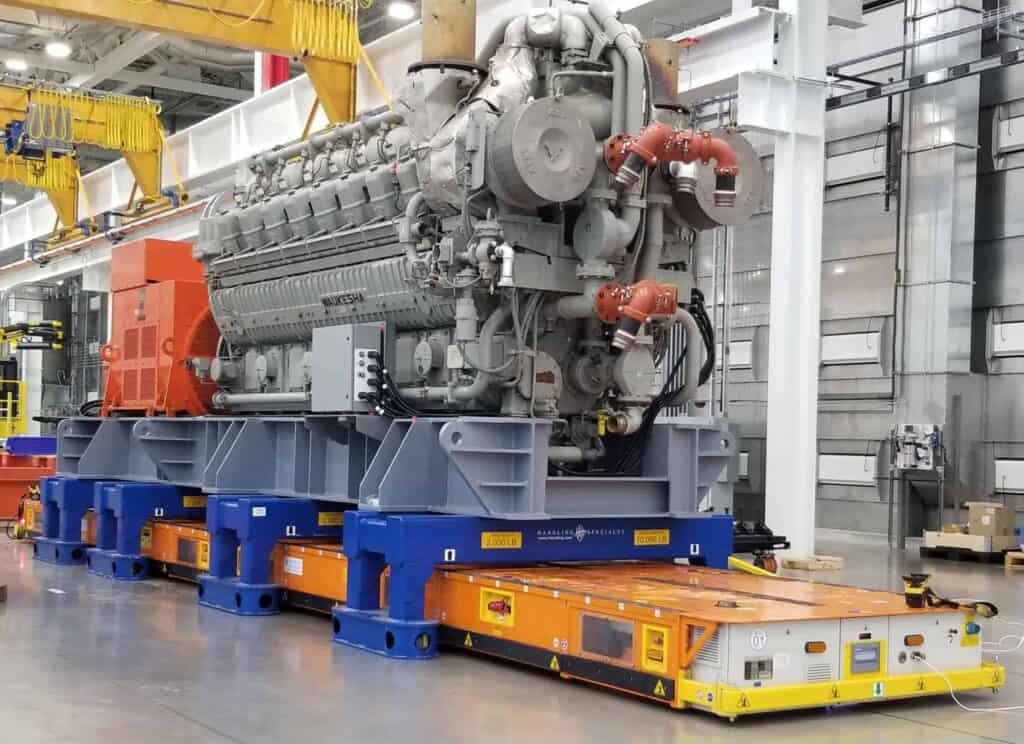

AGV product quality and reliability are fixed factors in the selection process. Assessing the robustness of the manufacturer’s vehicles, including durability, precision, and adherence to safety standards, is paramount. Reliability extends beyond the hardware to encompass software stability and fault tolerance mechanisms. A thorough evaluation of product quality and reliability safeguards against operational disruptions and costly downtime. The manufacturer’s ability to customize your AGV system with specialized tooling and options like scissor lifts and other material handling tools should be top of mind when considering a design/build firm.

AGV warranties and support offerings are indicative of a manufacturer’s commitment to customer satisfaction. Comprehensive warranties provide assurance against manufacturing defects and component failures, minimizing financial risks for the end-user. Equally important is the availability of responsive and knowledgeable support services. Timely assistance with troubleshooting, maintenance, and spare parts procurement ensures smooth operations throughout the lifespan of the AGVs.

AGV Customization and Scalability

Customization capabilities enable AGV manufacturers to tailor solutions to specific operational requirements. Assessing the extent of customization options, from vehicle configurations to software adaptations, empowers organizations to align AGV functionalities with their unique needs. Furthermore, scalability is essential to accommodate future growth and evolving operational demands. A manufacturer capable of delivering scalable solutions ensures long-term viability and agility.

AGV Cost Considerations

While cost is a significant consideration, focusing solely on upfront expenses can be shortsighted. Conducting a comprehensive cost analysis involves evaluating the total cost of AGV ownership, encompassing acquisition costs, maintenance expenses, and potential productivity gains. Striking a balance between initial investment and long-term value is essential. A higher upfront investment in a reliable, feature-rich AGV system may yield greater returns in terms of efficiency and longevity. An AGV manufacturer with a long history of designing and building AGVs will be a wealth of information and experience to fall back on.

AGV After-sales Support and Services

The quality of after-sales support and maintenance services directly impacts the uptime of your AGVs. Assessing the manufacturer’s service infrastructure, including response times, IIoT, technician expertise, and spare parts availability, is critical. Transparent service level agreements (SLAs) delineating maintenance schedules, support channels, and escalation procedures foster accountability and reliability. Prioritizing manufacturers with a reputation for exemplary after-sales support mitigates risks and ensures ongoing operational excellence.

Choosing AGV Manufacturer: Building a Partnership

Ultimately, selecting the right AGV manufacturer is not merely a transactional decision but a strategic partnership. Cultivating a collaborative relationship based on mutual trust, communication, and shared objectives fosters innovation and continuous improvement. Regular dialogue, feedback exchange, and joint problem-solving contribute to the evolution of AGV solutions that align seamlessly with organizational goals. Choosing an AGV manufacturer that has worked in your industry, and shares your vision and values is the cornerstone of a successful partnership.

Choosing the right Automated Guided Vehicle manufacturer requires a holistic approach encompassing technological capabilities, customization, product quality, after-sales support, and alignment with operational goals. By conducting thorough assessments, evaluating reputations, and prioritizing long-term value over short-term costs, organizations can forge partnerships that drive efficiency, innovation, and competitive advantage in the era of automation.

Contact one of our technical salespeople to learn more about choosing the right AGV for your industry requirements.