Key Highlights

- Industrial positioning equipment plays an important role in various assembly industries by providing precise and controlled positioning.

- The evolution of positioning technology has led to advancements in navigation and repeatability.

- Key components of industrial positioning systems include positioning devices, actuators, and bearings.

- There are different types of industrial positioning systems, including single-axis systems and multi-axis systems.

- Custom positioning equipment must possess features such as accuracy, repeatability, and load capacity.

- Industrial positioning equipment finds applications in manufacturing and assembly lines, robotics, and automated systems.

Introducing Industrial Positioning Equipment

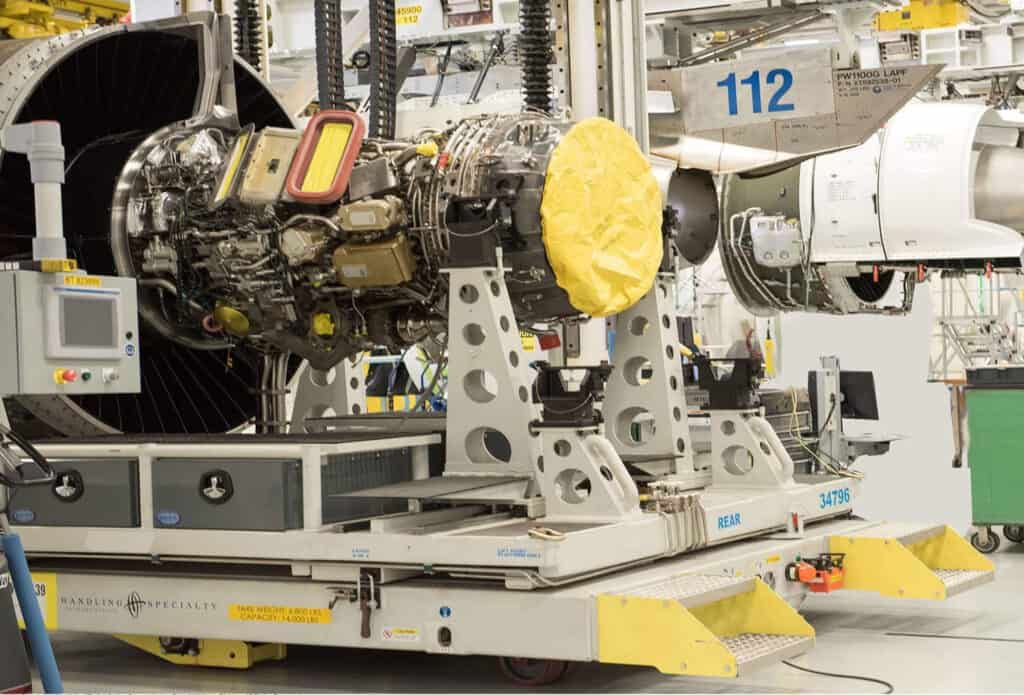

Industrial positioning equipment enables precise and controlled movement in various applications. From manufacturing and assembly lines to MRO and automated systems, industrial positioning equipment plays an important role in optimizing processes and improving efficiency.

With advancements in technology, industrial positioning equipment has evolved to provide even higher levels of precision and flexibility. These cutting-edge systems utilize advanced navigation techniques and offer enhanced repeatability, ensuring reliable and accurate positioning.

Understanding the fundamentals of industrial positioning equipment is essential to appreciate its potential applications. By exploring the key components, customization, and critical features of positioning equipment, we can gain a deeper understanding of how this technology revolutionizes assembly, MRO, and manufacturing processes.

Let’s discuss industrial positioning equipment’s evolution, components, customization, features, applications, and future trends. Whether you’re involved in machine and plant engineering, automotive manufacturing, aerospace, power generation, or any other industry that requires precise positioning, valuable insights into the world of cutting-edge industrial positioning equipment will be discussed here. So let’s dive in and explore the fascinating world of industrial positioning technology.

Understanding Industrial Positioning Equipment

Industrial positioning equipment combines a range of systems and devices that enable precise and accurate movement in various industrial applications. These systems utilize advanced technologies to achieve precise linear motion and ensure the positioning of objects with high levels of accuracy. Automated Guided Vehicles, personnel lifts, multi-post lifts, headstock/tailstock positioners, turntables, and more are considered positioning systems.

One of the key components of industrial positioning equipment is the positioning device, which is responsible for converting the input signal into the desired motion. This could involve translating rotational motion into linear motion or vice versa. The actuator, another crucial component, is responsible for generating the force required to move the object being positioned. It can be driven by hydraulic, pneumatic, or electric power.

Precision is a critical aspect of industrial positioning equipment as they are designed to achieve precise positioning within tight tolerances, allowing for accurate and repeatable motion. This precision is achieved through the use of high-quality bearings, which minimize friction and ensure smooth and precise movement.

Industrial positioning equipment finds applications in a wide range of industries, including manufacturing, automotive, aerospace, and robotics. Whether it’s moving components along an assembly line, guiding robotic arms, or positioning materials during manufacturing and MRO processes, industrial positioning equipment plays a crucial role in optimizing efficiency and ensuring precise control over motion.

Industrial positioning equipment provides the foundation for accurate and controlled movement in industrial settings, enabling industries to achieve high levels of precision and efficiency in their operations. Technicians and robots alike depend on exact positioning to perform their duties, and positioning solutions are critical in making these processes efficient and ergonomic.

The Evolution of Positioning Technology

Industrial positioning devices have undergone a remarkable evolution, propelled by advancements in precision and automation. From basic single-axis systems to sophisticated multi-axis setups, the technology has transformed significantly. Key components such as sensors and limit switches enable safe absolute positioning within industrial settings. Innovations like motion control systems and enhanced repeatability have improved the way industries approach precise positioning. This evolution showcases a shift towards more efficient and accurate industrial positioning solutions.

Key Components and How They Work

Key components of industrial positioning devices include precision actuators, sensors for feedback, and control systems. Actuators drive linear motion, while sensors provide accurate positioning data. Control systems interpret sensor inputs to adjust position and velocity. Precision is crucial for smooth operation. These devices ensure safe absolute positioning, which is vital in industrial settings, i.e. performing welds and affixing parts during the assembly processes, allowing for efficient and reliable work.

Customization of Industrial Positioning Systems

While discussing the customization of industrial positioning systems, it’s important to focus on single-axis systems and multi-axis systems. Single-axis systems provide basic but crucial linear motion for various applications, while multi-axis systems offer enhanced precision and flexibility, enabling complex movements and positioning tasks. By understanding the distinctions and applications of these systems, organizations can choose the most suitable industrial positioning devices for their specific needs. Additionally, customization can include multiple additional features including sliding bridges, visual and audible alarms, limit switches, and tooling setup for pneumatics and water hoses.

Single-Axis Systems: Basics and Applications

Single-axis systems involve linear motion along a single direction, making them suitable for straightforward applications like lifting systems. These systems often utilize sensors for precise positioning. For basic tasks requiring safe absolute positioning, single-axis systems offer a reliable solution. Understanding the basics of these systems will assist in optimizing efficiency and accuracy in various industrial settings.

Multi-Axis Systems: Enhancing Precision and Flexibility

Multi-axis systems enhance precision and flexibility in industrial settings such as assembly, MRO, and manufacturing. By incorporating multiple axes of motion control, these systems enable intricate movements and precise positioning. They are ideal for applications requiring complex maneuvers and accurate positioning within three-dimensional spaces. With the ability to control multiple axes simultaneously, multi-axis systems offer enhanced versatility for a wide range of industrial tasks.

Critical Features of Custom Positioning Equipment

These devices ensure precise linear motion using additional custom features. Safe absolute positioning is important for seamless operations, offering reliability and safety. Factors such as load capacity and the technology used, like single sensor systems, determine the equipment’s precision. Safety and ergonomics are also customizable features to ensure operator and product safety. Specialized tooling available to the technicians can also be affixed to any industrial positioning equipment to assist in efficiency.

Accuracy and Repeatability: Why They Matter

Precision and accuracy ensure that the system reaches the intended position precisely, while repeatability ensures that it can repeatedly return to that position reliably. These factors are especially vital in automated processes and manufacturing where the slightest deviation can lead to errors or product defects. Handling Specialty appreciates that investing in high-accuracy positioning devices guarantees efficiency and quality in operations, making them indispensable for industries relying on precise positioning solutions.

Load Capacity: Matching System to Application Needs

Hiring a company like Handling Specialty, which has decades of experience designing, building, and maintaining material handling equipment is an important step to customizing your equipment’s load capacity. Load capacity refers to the maximum weight the system can support effectively. Matching the system’s load capacity to the application requirements ensures optimal performance and longevity. Factors like the weight of the payload, forces during operation, and environmental conditions impact an engineer’s decision as to the lifting and holding capacities of an industrial positioner. Whether it’s lifting heavy loads in manufacturing or precise positioning in MRO operations, selecting the right load capacity is essential for seamless operations and preventing system failures.

Applications of Positioning Equipment in Various Industries

Manufacturing and assembly lines benefit from precise positioning devices to streamline processes. Robotics and automated systems rely on accurate linear motion for seamless operation. Both industries require high repeatability and safe absolute positioning to ensure efficiency and worker safety. From automotive to aerospace, industrial positioning systems play a crucial role in enhancing productivity across diverse sectors.

Manufacturing and Assembly Lines

By integrating precision positioning systems into assembly and manufacturing lines, processes benefit from accurate linear motion control. Ensuring safe absolute positioning and repeatability is important in these environments where level loads may need lifting or navigation. Choosing the right actuators and bearings, and meeting ANSI or SIL standards is essential to maintaining efficiency and safety in high-demand manufacturing settings.

Choosing the Right Positioning Equipment for Your Needs

Consulting with manufacturers like Handling Specialty can provide insights into custom solutions tailored to your application. Consider aspects like load capacity and accuracy to ensure the chosen equipment aligns with your operational demands. By evaluating these factors carefully with a seasoned, technical salesperson, you can optimize the performance and efficiency of your industrial processes with the most suitable positioning equipment.

Consulting with Manufacturers for Custom Solutions

When seeking custom solutions for industrial positioning devices, consulting with manufacturers, like Handling Specialty is a no-brainer. Handling Specialty can tailor the equipment to specific needs, ensuring optimal performance. By discussing requirements like precision, load capacity, and integration with existing systems, bespoke solutions can be developed. This personalized approach guarantees that the positioning devices meet the exact specifications of the application. Collaboration with manufacturers allows for the creation of tailored solutions that align perfectly with the operational requirements.

Future Trends in Positioning Equipment Technology

Integration with IIoT (Industrial Internet of Things) and Smart Factory concepts revolutionize industrial positioning devices. Advances in materials and designs optimize performance, ensuring efficiency and reliability. Enhanced precision and navigation capabilities cater to evolving industry demands. The binding of safe absolute positioning and cutting-edge motion control systems propels the sector forward. Stay abreast of the latest in positioning technology for seamless integration into dynamic manufacturing landscapes.

Integration with IIoT and Smart Factory Concepts

IIoT technology 4.0 allows for seamless communication between positioning equipment and other factory systems. By incorporating sensors and connectivity features, these devices can provide real-time data on position, speed, and performance. Smart factory initiatives aim to optimize production processes through data-driven decision-making, enhancing overall efficiency and productivity. The integration of industrial positioning equipment with IoT paves the way for smarter, more automated manufacturing environments.

Advances in Materials and Design for Enhanced Performance

Innovations in materials like high-strength alloys and composite structures contribute to increased durability and efficiency. Moreover, specialized designs catered to specific applications offer improved precision and reliability. Integrating cutting-edge technologies such as smart sensors and predictive maintenance capabilities continues to elevate equipment performance, meeting the evolving demands of modern industrial processes.

What Have You Learned?

Industrial positioning equipment offers precision and efficiency across various industries. Understanding the evolution, key components, and types of systems is important for optimal performance. Customized equipment must prioritize accuracy, repeatability, and load capacity to match application needs. From manufacturing to robotics, choosing the right system involves considering speed, stroke, and environmental factors. Future trends indicate integration with IoT and smart factory concepts for enhanced performance. Routine maintenance and safety protocols ensure longevity and operational safety.