How do you change a windshield wiper on a rail vehicle that has a curved and sloped front?

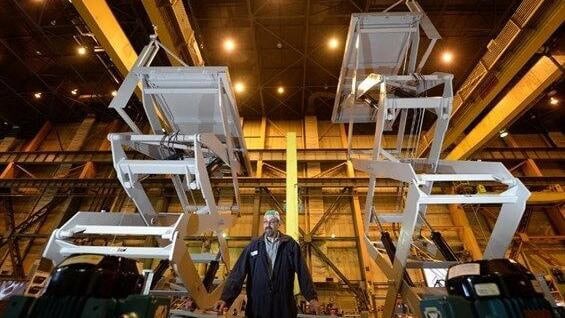

Many companies have turned to using Handling Specialty’s Nose Cone Gantry. Our equipment provides a safe yet flexible method of accessing these areas on a rail vehicle, almost anywhere in your facility.

Our gantry is a battery-powered, mobile hydraulic scissor lift/personnel lift designed to match the front curvature of your rail vehicles. While in its rail mode, the Operator can drive the machine to the front of the rail vehicle from its raised platform. The Operator can raise and lower (and forward advance) the machine to get the required safe access for the work they have to perform.

Once the work on the rails is done, the machine can be driven to an area for de-railing, allowing the Operator to raise the machine’s rail wheels, either from the platform or via a remote control, so it can now be driven on the road surface to its next area of operation.

These nose cone gantries include a gel-cell rechargeable power supply complete with a charger and can operate on tracks and flat ground. A handheld joystick steering control allows for ease of maneuverability, controlling traverse movement and platform up and down positions. The gantry includes non-conductive guardrails and a platform (fibreglass) for added safety, a keyed safety interlock system and sensors to prevent platform collisions.

If your rail maintenance facility does not currently employ this piece of handling equipment, consider contacting Marek Cybula at Handling Specialty.

For more on these units and to view the video, visit this link.