Improving how we handle materials in assembly and maintenance repair operations (MRO) applications is an essential part of being efficient. Below the Hook lifting equipment offers custom designs to fit your specific needs. These systems change how goods are moved in assembly lines and help transport heavy loads safely and efficiently. This boosts productivity, strengthens workplace safety, and helps create a smoother and cheaper manufacturing process.

Understanding Below the Hook Lifting Devices in Manufacturing

Below the Hook Lifting Devices include different designs engineered to lift, lower, and move heavy loads in a factory. These systems are usually attached to the hooks of large, heavy-duty cranes and hoists that move along the building’s ceiling. They help make moving materials easier and faster.

Whether attached to an overhead crane, also called a bridge crane or a gantry crane, these tools require a hoisting system. They can handle heavy objects as they circumvent the facility. This means workers do not have to rely on manual labor to lift and move heavy items. This change helps keep workers safe and speeds up the production process.

The Evolution and Functionality of Below the Hook Lifting Devices

Below the Hook Lifting Devices have undergone significant evolution, transitioning from basic hooks attached to chains to advanced, electric-controlled devices designed to handle the products found in today’s factories. As material handling processes became more intricate, the demand for robust and efficient lifting solutions also surged. This adaptability to changing manufacturing needs underscores the functionality and relevance of these devices.

These systems are essential in different sectors right now. Some of these sectors include automotive manufacturing, aerospace engineering, nuclear, and steel production. These below-the-hook devices allow overhead cranes to carry heavy loads, making them perfect for moving large components, raw materials, and finished products within big industrial environments.

Also, Below the Hook Lifting Devices have grown to provide better precision and control. This precision allows manufacturers to place heavy items accurately, instilling a sense of confidence in the assembly work and detailed manufacturing processes. The evolution of these devices should give you confidence in their ability to handle your manufacturing needs.

Types of Below the Hook Lifting Devices and Their Industrial Applications

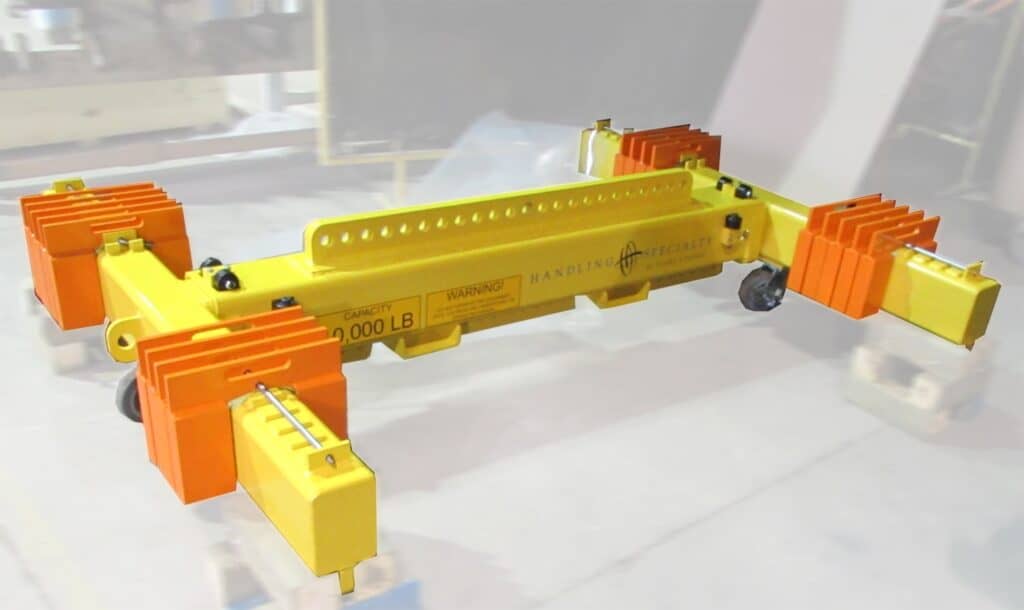

The different needs of modern manufacturing have led to many types of Below the Hook Lifting Devices. Each type is designed for specific jobs and carrying capacities.

The flexibility of engineering the right Below the Hook Lifting Device makes it common in nearly every industry that needs to move heavy materials, via overhead cranes. Picking the right device usually depends on the needs of the manufacturing process, how much customization is required, and the budget.

Enhancing Manufacturing Efficiency with Below the Hook Lifting Equipment

Below the hook lifting equipment is very important in making the most of the floor space in a manufacturing facility. It uses the space above, which opens up valuable floor area. Forklifts or other ground-based material handling equipment would generally take up this area. Because of this, workflow becomes more efficient, and the layout improved.

Also, these below the hook lifting systems lower the need for manual labor to move heavy items. This helps reduce the chance of workplace injuries and boosts productivity. Jobs that once took a lot of time and manpower can now be done quickly and effectively, leading to a faster production cycle.

Reducing Bottlenecks in Assembly Lines Through Smart Lifting Solutions

The smooth flow of materials is important for keeping production running without downtime. Below the hook lifting systems can transport heavy loads quickly and safely, helping prevent assembly line problems. By providing a constant supply of raw materials and parts to different workstations, they help avoid delays so the production line stays on track.

Modern below the hook lifting systems include advanced control systems. These systems allow for accurate positioning and movement of heavy items. This control lowers the risk of accidents and ensures materials reach the right locations correctly. It also cuts down on mistakes and extra work.

By enabling safe, fast, and precise movement of materials, smart lifting solutions help create a more efficient manufacturing setting. This results in quicker turnaround times, higher output, and higher profits.

Improving Part Handling and Precision in Manufacturing Operations

Complex products often require careful handling of delicate and heavy parts. Below the hook lifting devices have safety features and advanced controls. These systems provide the accuracy and security needed for these tasks. They help transport delicate parts without damage, keeping the final product intact.

The precise control from below the hook lifting devices also helps handle parts more precisely. Moving heavy objects smoothly lets workers place and align components exactly. This is essential in sectors like automotive manufacturing and aerospace.

Using below the hook lifting devices to move raw materials, work-in-progress, and finished goods via a crane makes the manufacturing process more straightforward. It reduces human error and helps maintain good quality throughout the production line.

Safety and Precision: The Dual Benefits of Below the Hook Lifting Technology

Modern overhead lifting equipment is not just about efficiency its about safety. With features like overload protection, emergency stop buttons, and anti-collision systems, these systems are designed to lower the risk of accidents in a manufacturing facility. Predictive maintenance, which uses sensors and data, also reduces downtime, helping keep the equipment running safely. This emphasis on safety should make you feel secure in your operations.

The focus on safety, combined with the precise control of advanced below the hook lifting devices, creates a safer work environment. Workers are protected from hazards when handling heavy loads, and the manufacturing process improves through better accuracy and fewer errors.

Case Studies: Below the Hook Lifting Devices in Action

The effect of below the hook lifting equipment on manufacturing performance is clear from real-life examples. In the Rail industry, for example, overhead cranes are vital in moving heavy engine parts, chassis pieces, and finished HVAC systems during different assembly steps. This helps speed up production cycles and makes work safer by reducing manual handling of heavy loads.

As the crane lowers the below the hook lifting equipment to the railcar roof, the leveling spreader bar will adjust to the center of gravity during and after the lift with an individual radio-controlled, hand-held unit the crane operator will have.

Choosing the Right Below the Hook Equipment for Your Assembly Line

Choosing the appropriate below the hook lifting equipment is a critical decision for any manufacturing plant. Factors such as the type of materials to be handled, the weight capacity required, available floor space, and any customized tooling needs should be carefully considered. This emphasis on the selection process guides the reader in making informed decisions that best suit their assembly line requirements.

To make operations smoother, looking closely at your manufacturing process and finding any parts where problems may happen is essential. Businesses can select the right material-handling equipment by studying how materials move and knowing what each workstation needs. This can help boost productivity and ensure a good return on investment. It’s a good idea to talk to experienced below the hook lifting equipment makers and get expert advice. This will help you make smart choices that fit your business needs.

Factors to Consider for Custom Over-Head Lifting Solutions

While standard below the hook lifting equipment serves many general purposes, custom solutions cater to unique requirements and optimize efficiency for specific tasks. When considering a custom below the hook lifting solution, factors such as the weight and dimensions of the load, the lifting height and span, and the environmental conditions of the facility must be taken into account.

Furthermore, the level of automation and integration with existing systems should be evaluated to design a solution that seamlessly integrates into the existing manufacturing process.

By considering these factors and collaborating with experienced manufacturers, businesses can acquire custom overhead lifting solutions that increase productivity, enhance safety, and provide a significant return on investment.

Conclusion

The below the hook lifting equipment can assist in making an assembly line work more efficiently and safely. New technology and custom solutions help manufacturers fix problems, work more accurately, and ensure consistent results. These systems are used in industries like Rail and aerospace, providing unique solutions that blend well with what companies already do. Picking the right, custom below the hook lifting equipment is essential for improving production and boosting output. By focusing on safety and accuracy, businesses can improve their assembly line work and reach greater success in overall operations.