What Custom Material Handling Equipment is Required for the Automotive Manufacturing Industry?

There is no design/build firm more qualified to answer the question, and in this short post, we will offer several options to support your automotive manufacturing facility’s custom material handling needs. All of Handling Specialty’s custom equipment is designed with redundant safety systems. These automotive industry solutions may include the following, depending on your facility’s processes:

- An Overhead Belt Lift is designed to be integrated into an automotive manufacturer’s overhead conveyor system to move vehicle bodies through the assembly line. The belt lift will lower, pick up the vehicle body and lift to appropriate heights.

- A Hydraulic Vehicle Lift can be used for several functions in testing the final product. This lift was designed and hot dip galvanized specifically to perform in a water spray booth, testing for leaks in a vehicle. The lift rises and lowers to precisely position the vehicle.

- Mast Style Belt Lifts, also referred to as Vertical Drop Lifts, transfer chassis in an automated assembly line from one level of the automotive manufacturing process to the next.

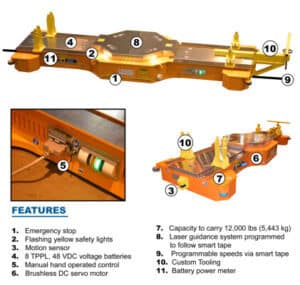

- Automotive Manually Guided Vehicles allow operators to direct heavy loads to and from a storage area and bring parts to the assembly line, all under battery power, eliminating exhaust fumes and bulky equipment experienced by forklifts.

- Automatic Guided Vehicles are an advanced option when designing a new or refurbishing an existing automotive manufacturing line. These AGVs are pre-programmed to follow a specific course, stopping at work cells through the assembly process as technicians perform their work. Like an MGV, these units can be outfitted with custom tooling, rotators, scissor lifts, turn tables, and other custom equipment.

- Custom Scissor Lifts for Marriage Applications offers the assembly line a seamless marriage of the front and rear axles with the vehicle body. Scissor lifts are a prominent feature within the automotive assembly line.

- Automotive Custom Scissor Lifts play multiple roles in the assembly of vehicles. These scissor lifts can be actuated via hydraulic, electro-mechanical, or pneumatic. Let your technical salesperson help you understand the best solution for the application.

Maintaining your Custom Material Handling Equipment with IIoT

IIoT is an important aspect of keeping your automotive material handling equipment functioning at peak performance and Handling Specialty can outfit your custom equipment with an IIoT system. Being proactive with your material handling systems can prevent accidents, component wear, and malfunction and prolong the life of your equipment.

What Constitutes Automotive Assembly?

When referring to the Automotive industry, remember that we’re not just talking cars. The term Automotive covers a large range of vehicles from compact cars to sedans, pick-up trucks, SUVs, delivery vans, trucks of all sizes, and even motorhomes. The key to creating a safe and efficient assembly line for each of these manufacturers is the term custom.

The material handling equipment solutions vary with each sub-category of automotive assembly. Therefore, custom material handling design/build firms like Handling Specialty are your best choice to create a safe and efficient solution for your assembly facility.

Whatever the custom material handling application needs, Handling Specialty will support your build with a design created specifically for your automotive assembly line.