A gas turbine is a type of internal combustion engine that converts the energy from burning fuel into rotational motion that can be used to generate mechanical or electrical power. Gas turbines are employed across of wide range of industries including power generation, aviation, marine propulsion, oil & gas, offshore power, and a variety of industrial applications.

Gas turbines are complex machines that generally consist of three main sections: the compressor; the combustion system and the rotor. Air is drawn into the compressor section of the gas turbine. The compressed air is mixed with fuel and ignited causing a rapid increase in pressure and temperature. The hot, high-pressure gas from the combustion system flows through the rotor causing a series of blades to rotate. The rotating shaft of the rotor is typically connected to a generator or other mechanical device such as a propeller or compressor which converts the rotational motion into useful work.

A gas turbine overhaul is a major maintenance task that involves disassembling and inspecting the turbines’ components, repairing and replacing damaged parts as necessary, reassembling the turbine and final inspection and testing. The manufacture, maintenance, repair, and overhaul (MRO) of gas turbines, compressors and turbomachinery systems is a multi-step process that requires skilled capabilities and specialized, robust equipment.

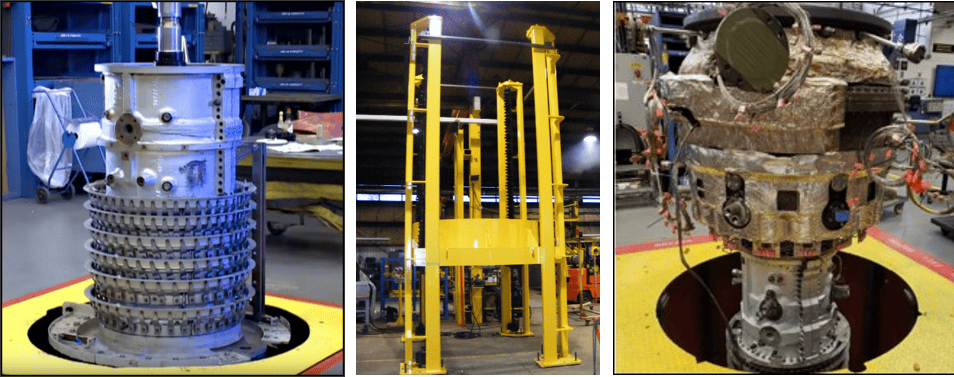

Turbine Assembly & Stacking Platform – Vertical Assembly Cell

Gas turbines and gas turbine components tend to be physically large and very heavy. Turbine overhaul activities such as rotor stacking and unstacking operations require a safe, efficient, and reliable method of positioning technicians to the correct elevation to perform the required tasks. Historically, fixed height work stands or scaffolding have been employed for access to the rotors when in the vertical orientation. Overhaul and assembly platforms that incorporate adjustable, vertical positioning capabilities are a far superior alternative to traditional fixed-height platforms. These moving work platforms provide infinite vertical positioning of technicians to the exact location for stacking operations and put the worker in the correct ergonomic position.

Custom Adjustable Work Platform for Turbine Assembly & MRO

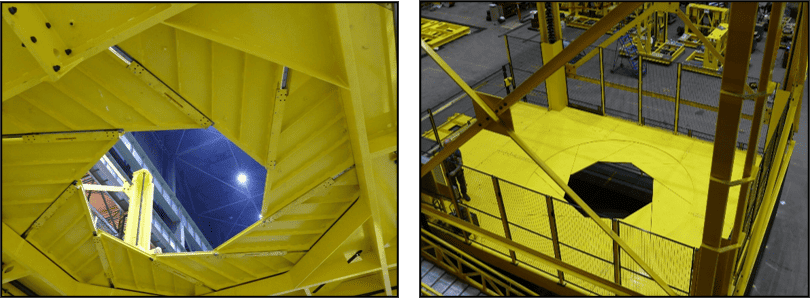

Alternatively, these systems can be configured to position the turbine itself to the correct elevation for ergonomic and safe access by the technicians. Vertical positioning platforms can be installed into pits within a facility and gaps between the pit edge and turbine are filled with heavy-duty, pit covers.

Large Capacity, In-Floor Lifting Systems for Turbine Assembly & MRO Operations

Openings in the platform can be manually altered using drop-in style filler plates to accommodate for the changing profile of the turbine. Platforms can also be equipped with adjustable openings that are actuated and automatically open and close like an iris as the turbine is raised and lowered.

Custom, Adjustable Platform Openings for Safety & Ergonomics

Turbine maintenance, repair, and overhaul operations also frequently require a means to move heavy loads within the facility. This task has been traditionally addressed via the use of overhead cranes, although in recent years, alternative methods employing manually guided vehicles (MGVs), large-capacity transporters, and automatically guided vehicles have been widely adopted. MGVs offer many benefits over traditional overhead cranes in that MGVs are extremely flexible and not restricted to a fixed path. MGVs can reach areas of the plant that are not accessible by cranes and can move loads from one building to another. Moving large suspended loads via cranes can create unsafe working conditions and disrupt production operations whereas MGVs provide a safe and efficient means to move heavy loads without interfering with ongoing activities.

Custom Manual/Automatic Guided Vehicle Solutions for Heavy Loads

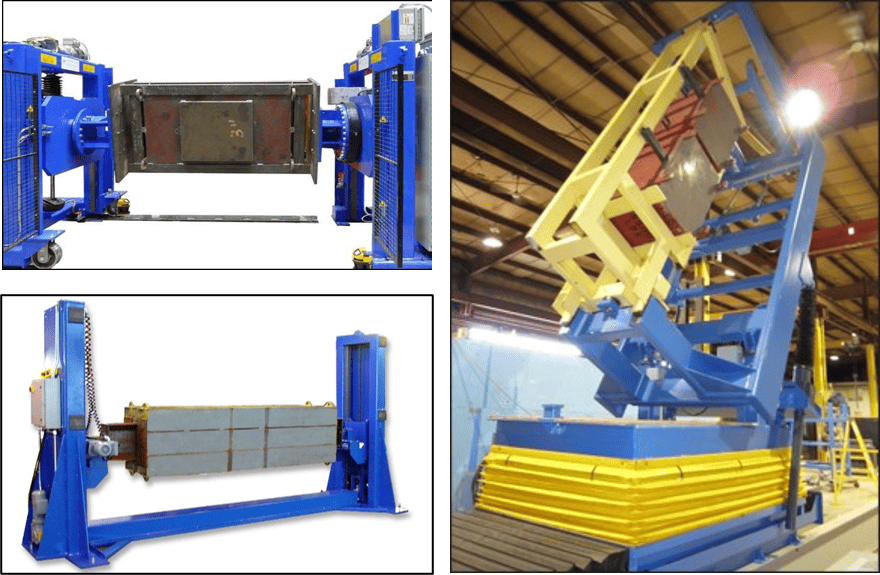

Small subassembly components that make up the gas turbine also require specialized tooling for safe handling during MRO tasks. These tasks can include inspections, cleaning, welding, repair, and machining. Positioning of these parts can often be difficult however employing custom work positioners can provide technicians with the means to lift, rotate, and orient the part to the correct position during MRO operations.

Custom Work Positioners for Rotating, Tilting, Lifting & Traversing

The equipment requirements of gas turbine, rotor, and turbomachinery MRO facilities can vary depending upon the specific type of products being manufactured or serviced. Given that each facility has unique technical and scope requirements, it is important for turbine MRO service companies to partner with material handling solution providers that have a creative engineering team that can collaborate with its clients; from conceptual engineering through detailed design. In addition to strong engineering capabilities, MRO companies should be looking to firms with extensive experience in the manufacture, test, installation, and support of safe, reliable, and robust equipment used in turbine assembly and overhaul operations.

Handling Specialty has more than sixty years of experience in providing custom-engineered material handling solutions to companies in the automotive, rail/transportation, aerospace, power-gen, entertainment, steel/metals, and advanced manufacturing sectors. Handling Specialty provides safe, efficient, and heavy-duty solutions for production applications involving large capacities, high-duty cycles, unique configurations, robust environments, and stringent process, quality, and safety demands. Handling Specialty builds big things to help its customers build big things.

Written by Michael Roper, Sales Manager