Handling Specialty works with clients in the nuclear industry to engineer and manufacture massive four post lifts, unique portable tilt and rotate platforms, gimble service lifts, bridges, retubing platforms, and many more custom products to assist in the refurbishment of nuclear reactors, nuclear waste storage, and day to day operations.

One of our massive four post lifts was used in a test facility to train nuclear technicians in the re-tubing process for refurbishing nuclear reactors. The lift was manufactured to extremely tight tolerances to comply with Z299.2 requirements. Case Study

The engineered and manufactured portable tilt and rotate platform was designed for draining dry storage containers (DSC) that held spent nuclear fuel rods at a nuclear facility in Ontario. An operator uses a hand pendant controller to rotate and tilt the DSC to allow water to drain from the container. The three-degree tilt angle must be maintained for 24 hours for complete drainage to occur. Case Study

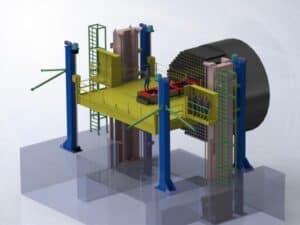

Handling Specialty and Atomic Energy of Canada combined forces in the design and manufacture of the lift system used to service AEC gimbles. The gimble is a device that is mounted to an overhead crane in the reactor tube area of a nuclear power plant. Positioned on the underside of the crane, the gimble is used to remove old fuel rods and insert new ones into a reactor. The system’s main lift is hydraulic, while the second lift is mechanical to ensure accurate positioning. Case Study

Our material handling solutions for the Nuclear industry have been procured multiple times since Handling Specialty’s inception and exhibit a proven success rate of meeting and exceeding the expectations of our clients.