How do you manage parts and services support for a floating city?

This is a big question that Handling Specialty has answered on several occasions for the largest cruise ships in the world. Currently, the Symphony of the Seas – Royal Caribbean’s latest – is the biggest and carries with it another Handling Specialty underwater stage system. This system is embedded in the ship’s aqua-theater located at the rear of the ship, with an incredible amount of technology both underwater and within the control room.

As you can imagine, electrical safety devices like tape switches don’t behave the same in a water environment as they might in a dry space. Hydraulic Power Units, used to add fluid power to the lifting and lowering systems of the three-part stage, require experienced and dedicated valuation 24/7 as well.

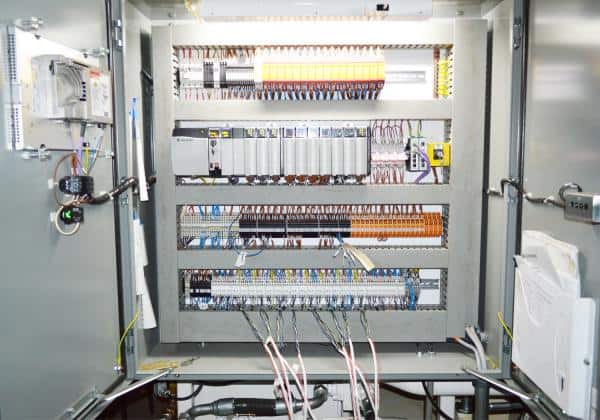

In order to keep ahead of any major downtime, Handling Specialty employs a state-of-the-art IIoT system to remotely access and diagnose issues within the system, relaying them to Royal Caribbean’s onboard engineers. “They have really excellent engineers,” comments Marek Cybula, Handling’s Professional Services Specialist, “They are the ones doing monthly inspections and physical service, such as filter changes, nitrogen top-ups, adjustments, replacement of consumable items, etc. Any major component replacement is done by them as well, under our technical assistance and subsequent re-tuning of the system.” Even so, Handling Specialty has embraced the Internet of Things in many of its controls and equipment in order to offer a higher level of service to its customers who are often inaccessible, such as cruise ships.

Royal Caribbean purchases a pre-determined parts list for quick and reliable service with their underwater stage lift system. Depending on the work required in a service capacity, Handling Specialty could see up to 6 technicians returning to the ship during a session. Cybula adds, “At the five-year mark, Handling Specialty sends a crew of technicians – while the ship is in dry-dock for major services or refurbishment.”

Understandably, an aqua theater on a ship at sea experiences higher than normal stresses with many shows and activities between shows. There is a lot of wear and tear on the equipment and controls. Stresses due to the equipment being secured to a moving vessel, equipment exposed to storms, rain, the Caribbean sun, heavy chlorine etc. Just a few reasons why Royal Caribbean Cruise Line keeps coming back to Handling Specialty. With four ships now housing the aqua-theater, they are confident in Handling’s ability to deliver quality equipment, installation and services to keep their performers working and their audiences entertained.

Visit our page for more on Handling Specialty’s Parts & Services Group. Visit our pages for more on the aqua-theater and underwater stage lifts.