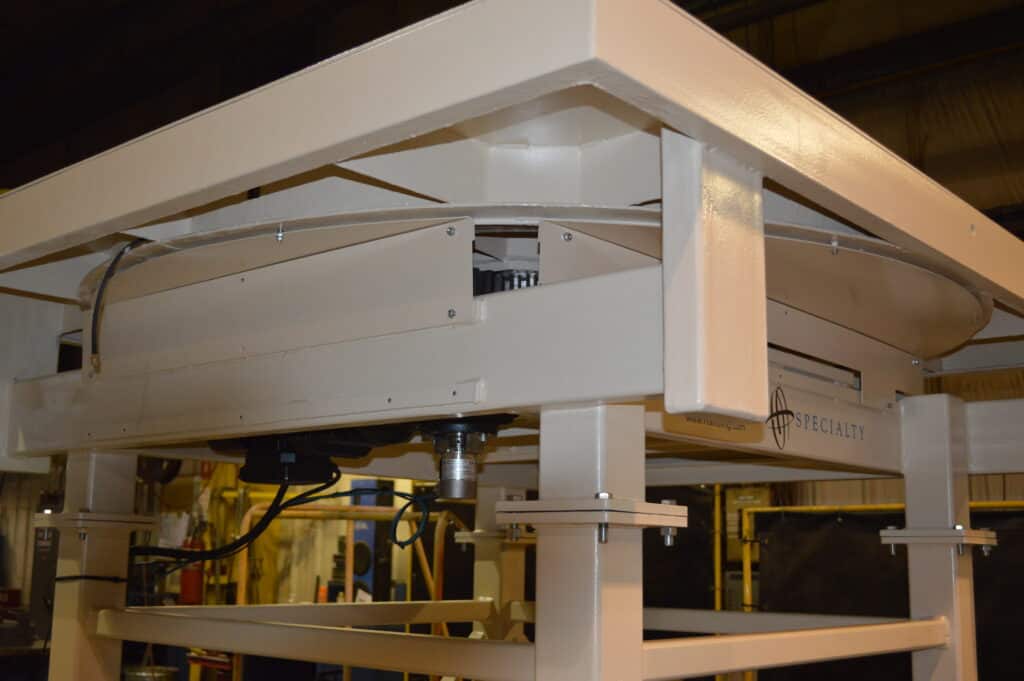

Wind Tunnel Turn Tables

Overview A major wind tunnel engineering firm required two turntables for a wind tunnel they will place in a Texas University. Handling Specialty’s designs offered the project everything they’d asked for, including controls which allow the operator to customize the stop-position of the rotating top, set designated stops and run clockwise and counter-clockwise.

Automatically Guided Roll-Over Vehicle

Overview Automatically Guided Roll-Over Vehicles These custom-engineered, automatically guided roll-over vehicles were developed to safely and efficiently position large power-gen engines during major overhaul and remanufacturing operations. The roll-over capabilities of this equipment provide ergonomic positioning for operators and technicians while working with the engines. Engineered to operate manually or automatically by following a pre-determined […]

Custom Work Positioners

Overview Custom work positioners come in many shapes and sizes for the material handling industry. From rotating headstock-tailstock units positioning product at ergonomic levels and offering 360-degree access to four post lifts raising product for precise positioning. The iron and steel industry often requests custom work positioners to effectively and efficiently perform their tasks. There […]

Engine Rollover and Lift Stations

Overview Handling Specialty recently completed a 15 and 30 Ton Engine Rollover Station for the energy industry, which was placed in a state-of-the-art manufacturing facility. Handling Specialty also provided installation and commissioning of these products. The Engine Rollover Stations will be used to position reciprocating engines during manufacturing operations. Features The rollover feature, along with […]

Tilt and Rotate Platform for Nuclear Industry

Overview Handling Specialty engineered and manufactured a unique portable tilt and rotate platform for draining dry storage containers (DSC) that hold spent nuclear fuel rods at a nuclear facility in Ontario. The process begins when a full container is lifted from a pool of water via a crane and placed on the rotator. An operator […]

Rotating Mast Lift for Tooling Inspection

Overview Handling Specialty engineered and manufactured a custom two-post rotating mast lift for an international power company’s (GE) power generation facility for turbine equipment inspection. Features Mechanical actuation is used for positive locking, which allows the tooling to be held at any elevation for extended periods of time. The lift must be in full “up” […]