Leadership

The people and experience of Handling Specialty are a testament to a company that is continuing to evolve and grow. With ongoing recruitment of talented people, quality improvements, and a willingness to raise the standard, Handling Specialty occupies a unique position in the material handling field.

Handling Specialty’s reputation is one of a competent problem-solver because we have built a reputation for providing unique, custom-engineered material handling or industrial automation solutions that stand the test of time.

This ability to solve problems has allowed Handling Specialty to achieve success in many sectors, including aerospace and defense, automotive, entertainment, rail/transportation, energy, process industries and advanced manufacturing industries.

Our motto is:

“We build big things to help our customers build big things.”

Why Us?

Your Best Option for Material Handling Equipment Design, Manufacturing and Service.

With decades of experience within the company’s respective fields, small-town values, and a proven track record for building, installing and maintaining innovative, dynamic, durable, efficient and personalized material-handling equipment for our customers, you’ve found a trustworthy partner in designing the solution – regardless the challenge – and engineering excellence and quality, which will take your company forward.

Our Facilities

Handling specialty currently operates out of two facilities. The first is our head office and manufacturing facility (Plant 1), with 40,000 sq. feet at 219 South Service Road in Grimsby, Ontario, and 100,000 sq. ft at Plant 2, at 1632 Burlington Street in Hamilton, Ontario. The Grimsby facility, known as Plant 1, also houses the head office. The Hamilton facility (plant 2) manages large-scale projects and those requiring large open test areas. In contrast, the Grimsby facility handles smaller-scale projects, pre-assemblies and R & D. With state-of-the-art manufacturing facilities and highly-trained personnel, Handling Specialty will assess, design, manufacture, and install Custom material handling equipment specific to your applications.

219 South Service Road West, Grimsby, Ontario, Canada

EST. 1963 - 40,000 square feet

Engineering | Sales | Parts & Services | Quality Assurance | Project Management |Purchasing | Operations | Accounting | Marketing | Conference Rooms |Shipping/Receiving | Manufacturing | Weld cells

Paint booth – 14’-0” wide by 25’-0” long

4 x 5 ton bridge cranes, 7 x .5 ton jib cranes

1632 Burlington Street in Hamilton, Ontario, Canada

EST. 2008 - 100,000 square feet

Blast booth – 45’ long, 11’ high and 16’ width

Paint booth – 45’ long, 11’ high and 16’ width

Manufacturing with 105′ ceilings | Quality Assurance | Operations | Project Management | Conference Rooms

Shipping/Receiving: 6, 21′ roll-up bay doors |Heavy-duty Cranes: | 18 weld cells | Hydraulic VMI work center | Power and Controls VMI and panel building center

Our Commitment to Quality

Quality Commitment to the Customer – Handling Specialty is dedicated to achieving customer satisfaction through our commitment to providing reliable, maintainable and durable products on time and continually striving to improve our product and quality system. Designing and building quality, custom materials handling equipment.

Customer satisfaction

Product quality

(including statutory and regulatory requirements)

Product durability

On-time delivery

Product reliability

Product maintainability

Corporate Brochure

Handling Specialty Manufacturing Ltd. is committed to providing a barrier-free environment for our clients/customers, employees, job applicants, suppliers, visitors, and other stakeholders who enter our premises or access our information services.

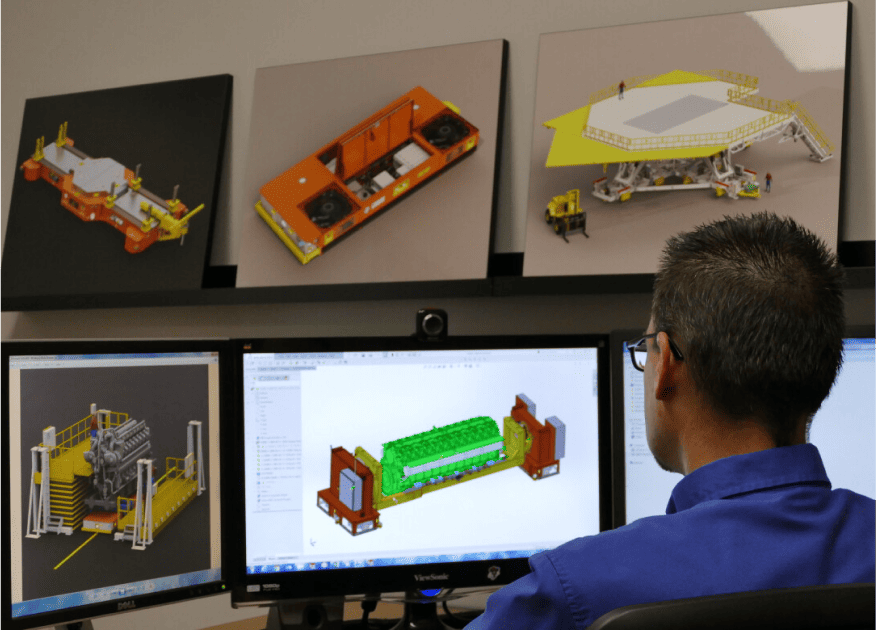

Core Competencies

Turn-key capabilities

Handling Specialty has a global reputation as an experienced design/build firm for large scale, custom turn-key material handling systems. Our full support services include:

Environmental Values

Accesibility

Handling Specialty Manufacturing Ltd. is committed to providing a barrier-free environment for our clients/customers, employees, job applicants, suppliers, visitors, and other stakeholders who enter our premises or access our information services.