What is the mechanism of a scissor lift used for?

What is the mechanism of a scissor lift used for?

The scissor lift mechanism is used extensively in many industrial lifting applications.

Scissor lifts are employed in many commercial and industrial environments where working at height or elevating a workpiece is a requirement. The size and specification of a scissor lift will depend on the application, ranging from building repairs or accessing materials stored at height in a warehouse facility to heavy-duty industrial applications in the automotive, aerospace, energy, entertainment, transport, and advanced manufacturing sectors.

There are different types of scissor lift mechanisms required for this wide range of applications. But how does a scissor lift work? This will cover scissor lift working principles, materials and the components used in the design and manufacture of scissor lifts, and other factors affecting their operation.

The scissor lift mechanism/scissor lift working principle relies on a set of cross-braced arms that move up or down to raise or lower a load-bearing platform attached to the top of the assembly. The power source needed to extend or retract the scissor lift mechanism for the up and down movement would depend on the platform size, operating height, and load handling of the lifting unit.

How does a scissor lifting mechanism work in practice? The specific mechanics of simple vertical lifting mechanisms will depend upon its power source, which can be hydraulic, pneumatic, electric, diesel, etc. However it is powered, the basic principle of lift mechanism design operation remains the same. So, using a hydraulic scissor lift mechanism as an example, the sequence is this:

- The scissor lift operator turns on the power source. Using a valve to control the flow of fluid or air starts to fill the cylinder(s) with hydraulic fluid (or compressed air in a pneumatic system).

- The scissor lift control system moves the hydraulic fluid or compressed air from the reservoir to the operating cylinders.

- The hydraulic cylinder pushes outwards for upward movement and causes the scissor legs to push apart, raising the platform.

- To lower the scissor lift mechanism, the operator uses a down valve to release the hydraulic fluid or reduce the pneumatic pressure level in the cylinder by returning it back to the reservoir, causing the scissor legs to retract.

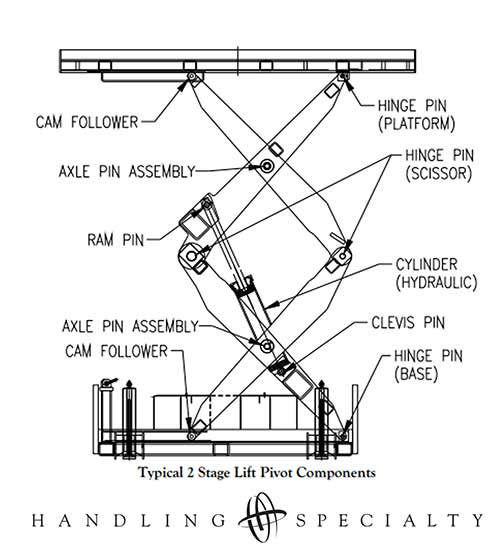

The scissor mechanism gets its name because the steel supporting beams under the work platform are hinged with pivot points to produce an assembly that looks like several sets of connected scissor blades. This crisscross or “X” pattern is also referred to as a pantograph mechanism.

When the scissor lift working mechanism pushes the base of the beams together, the structure extends, raising the work platform vertically. The scissor arms fold as the length of the base increases and extend as the length of the base decreases.

Geometrically, the configuration is inherently stable. The scissor lift mechanism presents as a series of connected parallelograms with hinged pivot-point intersections. This enables the operator to elongate or contract the mechanism while maintaining the integrity of the geometric figure and keeping the platform stable and parallel to the base.

One type of scissor lift mechanism that’s been around for a while is the mechanical system. A powered lead-screw or rack and pinion arrangement are employed to raise and lower the platform. Mechanical operating principles apply to the control of some small-scale scissor lift units that use hydraulics. A scissor lift table mechanism will typically have a foot lever and hydraulic pump to raise the table and a hand knob provides controlled lowering. Their compact design enables them to fit in confined spaces.

More common are scissor lift control systems that have electrical or electro-mechanical devices that provide maneuverability and control. Scissor lifts can have a control box with selector dials to move vertically and horizontally. Control boxes incorporate safety interlock systems to ensure the scissor lift will not move, or the scissor lift wheels won’t turn when elevated, emergency stop button, etc.

On modern systems, joystick lift controllers are often deployed to raise, lower, and move the platform. Most scissor lifts have an easy interface that enables the operator to perform height adjustment. Some scissor lift tables have pre-configured elevation heights.

As previously discussed, to raise or lower the platform, hydraulic fluid is forced into or out of the hydraulic cylinder(s) in a hydraulic scissor lift table mechanism. A check valve holds the hydraulic fluid in the cylinders, ensuring that the lift table remains at the selected raised position. Opening the down valve allows hydraulic fluid out of the cylinder at a controlled rate and lowers the lift table. An electric motor and hydraulic pump typically perform repetitive lifting and positioning, activated by the push of a button.

In a pneumatic system, scissor lift tables can be connected to on-site compressed air systems, eliminating the need for hydraulics, motors, pumps, or electrical connections. Durable airbags provide consistent and smooth height adjustment and lifting. A relief valve prevents pressure build-up and acts as overload protection.

In some scissor lift configurations, the working platform of the unit can rotate to provide the operator with greater accessibility. In hydraulic units, table control is accomplished via an electric motor and hydraulic pump that perform repetitive lifting and positioning operations with the push of a button.

To answer the question “How does a scissor lift work?” it is important to have an understanding of what components go into the design and manufacture of a scissor lift assembly.

Most scissor lifts will contain the following core functional components:

The platform on the top of a scissor lift mechanism can be of various sizes, shapes, and materials. Also known as a lift table, the platform is the working surface that bears the load of personnel or work objects that the scissor lift raises or lowers. Units that transport workers typically feature a platform with guard rails around its perimeter for fall protection. Platforms without rails are typically designed for lifting or lowering materials and inanimate objects.

The scissor legs are the crisscross array or pantograph configuration of fabricated metal struts that bridge the gap between the base and the platform. The maximum working height of the scissor lift mechanism will be dictated by the length of each scissor leg or the number of scissor legs. The scissor legs raise the platform as they constrict (draw closer together) and lower the platform as they expand and can be driven by different power sources depending upon the specified application.

A scissor lift mechanism will typically have an array of one to four compression / expansion cylinders attached. These cylinders may be filled with hydraulic fluid (hydraulic scissor lift) or compressed air (pneumatic pump system) depending on the specification and the operating environment. An increase or reduction of pressure through these cylinders attached to the scissor legs actuates the raising or lowering action of the scissor legs and platform.

This foundational part of the scissor lift mechanism is a sturdy footing made up of strong, rigid brackets. The base is engineered with tracks to guide the rollers at the bottom of the scissor legs. In conjunction with strong support from the base, these rollers ensure steady and stable raising and lowering of the unit. The size and configuration of the scissor lift base will depend on the model and its application.

There is a range of power sources that can be specified to power a scissor lift. These can range from self-contained motors that run on different fuel sources to remote power packs. The selection of the most suitable power source will be dependent on the operating environment of the scissor lift.

The down valve controls the flow of compressed air or hydraulic fluid back to its reservoir. The speed of this flow dictates the speed at which the platform will descend. The power source is connected to the down valve that controls the rate of descent.

Most scissor lifts are self-propelled and have a steering capability the operator can move the lifting mechanism using motor power to their required work area. Consideration must be given to the terrain that the scissor lift may encounter as it is being moved to the work area to prevent it from becoming stuck or unstable. Some smaller lightweight units for indoor work may not be self-propelled and require maneuvering by hand.

A scissor lift can be specified and manufactured to operate from various power sources depending upon the operating environment in which it will be deployed. The principal power sources include:

The electric-powered scissor lift mechanism is typically a compact unit with low noise. They are well suited for indoor work environments as they are emission-free. They are typically employed on smaller platforms and have lower load-bearing capacities than units. that rely on fossil fuels like diesel, gas, or propane. Smaller scissor lifts can be hauled or towed between job sites. For specific applications, scissor lifts may be mounted on an automated guided vehicle (AGV), a flatbed or railcar.

The Hydraulic scissor lift mechanism relies on cylinders filled with a reservoir of hydraulic fluid. This fluid maintains pressure on the lift and holds the working platform at the desired height when the unit is extended. The flow of hydraulic fluid is controlled by valves and causes the cylinder to push outwards or retract inwards, with a corresponding motion from the scissor legs. Relatively easy to operate, hydraulic scissor lifts are suitable for a range of applications at different scales.

Often used in construction, a diesel engine is the power source for this class of scissor lift. Diesel is more economical to use than gasoline and can generate very high torque with comparatively low rpm. Units are typically heavy-duty and accommodate larger platforms and heavier loads. Diesel units are generally favored for outdoor applications due to their noise and the emissions they produce. Some variants incorporate a hybrid drive for operating in closed job sites.

Pneumatic systems use air pressure to raise and lower the scissor lift mechanism. The scissor lift working system typically employs an airbag or multiple airbags, which are configured as single, double, or multiple, depending on the size of the scissor lift and its application. An air compressor elevates and positions the unit for working or simple loading and unloading. Pneumatic lifts do not emit noxious fumes and are a sustainable option for smaller-scale projects and indoor applications.

Now that you have a better understanding of “How does a scissor lift work?” and an understanding of the types of scissor lift mechanism available, you need to find a specialist vendor that can answer any questions about your scissor lift working requirements for your particular working environment and job scenario for your scissor mechanism buy.

Handling Specialty manufactures custom engineered material handling products for customers around the world. We are the premier source for made-to-order lifting, tilting, rotating, and traversing equipment for clients like you seeking innovative solutions, exceptional professional support, world-class credentials, and unmatched experience.

Our design capabilities and engineering expertise allow us to tackle your one-of-a-kind applications that may have unique or extreme requirements involving usage, operating environment, and weight capacity.

Whether it is a single custom personnel platform for a material handling integrator, a custom scissor lift, an automatic or manually guided vehicle for your manufacturing facility, or a major turn-key project for your multinational company, Handling Specialty has the team to make your project a success. We are your one-stop-shop for the design, manufacture, installation, and support of your project.

Handling Specialty is your best choice for an application-specific scissor lift as we have designed, built, and installed custom and standard scissor lifts for multiple industries, including automotive, aerospace, energy, entertainment, rail, transportation, and advanced manufacturing.

If you’d like to know more or discuss your project needs, get in touch with us.