The Flexibility of the Portable Scissor Lift

The Flexibility of the Portable Scissor Lift

Portable scissor lifts brings the capabilities of a fully-fledged industrial lifting system to confined or hard-to-reach spaces that would be inaccessible to a larger, fixed lift platform. These movable systems routinely provide service in several settings, including the entertainment industry, warehousing, manufacturing, and automotive repair.

The portable scissor car lift has the edge over other types of vehicular lifting systems in that these units combine versatility, ease of positioning, are lightweight, and have a considerable lifting and load-carrying capacity in a single package.

The portable scissor lift is a variant of the basic principle of the scissor lift mechanism, where a set of cross-braced arms move up or down to raise or lower a load-bearing platform attached to the top of the assembly. The portable scissor lift has the advantage of being mobile so that you can transport it under its own motive power to various working locations. Units are also typically compact and/or lightweight, allowing them to be transported by a single operator.

In situations where technicians need to elevate a car, SUV, or pick-up truck high enough to perform wheel service or other undercarriage operations, a portable vehicle scissor lift can be rolled into place to elevate the vehicle safely. This allows the technician greater access to perform various tasks on the elevated vehicle at a comfortable working height.

With compact form factors often designed for low ceiling environments, many portable scissor car lift types will fit in small workshops or home garages and do not need to be bolted down to the floor. This makes them ideal for users who are renting their workspace or whose leases do not permit them to drill holes into the floor for fixing heavy equipment.

While there are many different brands and models of portable scissor lift car hoists, they all have fundamental characteristics in common. Core components include:

- A sturdy base with wheels or rollers for movement.

- A set of scissor arms to raise or lower the unit.

- A solid platform fixed to the top of the scissor arms, which bears the load.

- A lifting system (typically based on hydraulics or compressed air pneumatics).

- A power source (which may be integrated with the transport system for the unit as a whole).

- A transport system for the unit.

- Safety locks and other features to ensure load stability and protection for operators.

Central to their operation is a scissor mechanism and adjustable lifting arm assembly. This arrangement will typically incorporate a safety lock bar with multiple lock positions. A portable scissor car lift will usually have a design that enables workers to service light-duty trucks and cars in shops or garages, often in work areas with limited ceiling clearance.

As we have already observed, there are several kinds of portable scissor lift and numerous brands and models of equipment on the market. This section will look at the various classes of lift and some of the specifications and models available.

A portable vehicle scissor lift of the low-rise category can offer a generous work clearance while taking up a limited amount of floor space. This makes low rise scissor lifts especially suitable for home garages and small workshops.

A portable low rise scissor lift is designed to have a minimal footprint that incorporates built-in wheels, no bolts, and an open-centre design with a high safety factor. These units can lift vehicles to a maximum height of 20 – 21 inches in about 30 seconds.

A Flush-Mount Pit Lift is a low-rise portable scissor car lift that can provide up to 6,000lb lifting capacity and a maximum height of 29 inches. It has built-in wheels, enabling users to create a workspace at various locations, and is designed so that it can be installed over a vehicle pit for fast oil changes and wheel service if required.

A heavy duty portable vehicle scissor lift has a lifting capacity of up to 9,000 lbs. Though slightly less portable, it is the most powerful open-centre, low-rise lift variant. It offers full undercarriage and wheel access; it can be used in home garages but is more commonly deployed in commercial applications.

A portable scissor lift of the mid-rise category offers slightly more working height and comfort than a low rise lift. However, mid-rise lifts require more overhead space to operate and are less portable. There’s still no requirement to bolt them down, so mid rise scissor lifts can be used in home garage scenarios.

The Mid Rise Lift has a power unit console that also doubles up as the wheels for the lift, hooking onto the base of the scissor structure and acting as a temporary lever for manoeuvrability. Once the lift’s built-in wheels are engaged, a single operator can roll the lift anywhere with ease. Mid rise lifts are popular for home garage use. However, the restricted lifting height provides limited access to a vehicle’s undercarriage, making it inappropriate to change oil, drop a transmission, or replace a muffler.

The Portable mid rise scissor lift has a lifting capacity of around 7,500 lbs. making this portable vehicle scissor lift ideal for commercial quick service bays and tire service specialists requiring extra lifting height. It can easily lift a 7,500 lb car or truck to a comfortable working height. The vehicle is evenly supported by positioning heavy-duty rubber blocks under the vehicle lifting points. This minimizes the potential for damage to the underside of the vehicle. Technical specifications for this model are:

- Weight Capacity: 7,500 lbs

- Overall Lift Length: 80.15″

- Overall Width: 73.22″

- Minimum Lift Height: 4.33″

- Maximum Lift Height: 41.33″

- Speed of Rise: 60 Sec

- Speed of Lowering: 55 Sec

- Table Length: 56.29″

- Table Width: 19.68″

- Required Air Pressure: 18 mpa

- Motor Size: 3 HP 2.2kw

- Voltage: 110v, 220v

An off the shelf portable scissor lift may not be appropriate if your job requirement and/or working environment have a specific need for equipment handling. In such cases, your best bet is to engage a specialist professional design firm’s services that can craft and construct a lift to your unique specifications.

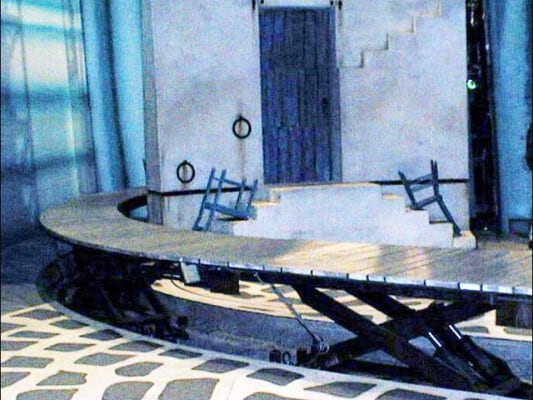

Handling Specialty custom engineers and manufactures custom lifts for any application. This stage lift was custom designed for the travelling stage production of Mamma Mia!, a major musical that appeared in New York, Toronto, and San Francisco. This hydraulic single stage lift has a lifting capacity of 2,000 lbs, and vertical travel of 24 inches. Feature highlights of the project include:

- Four scissor lifts with various-sized platforms are used in a serpentine pattern to lift and lower sections of the stage.

- Actuated by double-acting hydraulic cylinders, it has a design for cantilevered loading.

- Vertical travel rate of 2.4″ per second, low height of 8.5″, 2,000 lb. capacity for raising/lowering both the stage flooring and performers.

- Lifts feature soft starts/stops and minimal noise.

- Lifts were designed to be quickly and easily taken down and transported to each venue.

For the automotive industry, Handling Specialty solved a material handling challenge in a Canadian auto plant by custom engineering and manufacturing a high cycle, robust and durable lift system that transferred car bodies atop steel skids between two sets of conveyors set on different levels.

The lift has a powered conveyor mounted on top of it in the lowered position, where it receives a car body which is then carried onto a set of steel skids. The lift travels to the height of the upper conveyor, where the skids and car body are ejected.

The portable scissor car lift comes in many shapes, sizes, and specifications and how the design of different portable vehicle scissor lifts can assist home garage owners and professional workshops alike.

The portable scissor lift can manifest in highly specialized forms to cater to unique working environments and use cases outside of vehicle lifting applications.

Handling Specialty designs and manufactures custom-engineered material handling products for customers around the world. We are the premier source for made to order lifting, tilting, rotating and traversing equipment for clients like you seeking innovative solutions, exceptional professional support, world-class credentials and unmatched experience.

Handling Specialty is your best choice for an application-specific scissor lift as we have designed, built and installed custom and standard scissor lifts for multiple industries, including automotive, aerospace, power generation, entertainment, rail, transportation, and advanced manufacturing.

If you’d like to know more or discuss your project needs, get in touch with us.