What is an Automatic Guided Vehicle?

Automatic Guided Vehicle

Automatic guided vehicle systems, also known as an AGV system, otherwise known as an automated guided vehicle, autonomous guided vehicles, or even automatic guided cart, is a system that follows a predestined path around a facility. An AGV automated guided vehicle is a motorized vehicle that carries a load through either an assembly, manufacturing, or warehousing facility. An AGV can take on any form a customer requires to best address their application needs.

Understanding your facility’s specific requirements is an important aspect in choosing your AGV system. An assembly or manufacturing plant with demanding cycles and heavy products will need an automated guided vehicle that can operate to the stringent processes such an environment commands. Battery life needs to outperform most, welds must hold through extreme handling, and the equipment has to encourage confidence. Downtime must be a thing of the past as industrial Internet of things (IIoT) is built into each AGV unit. Spare AGVs should be considered to cover the line as charging times overlap, and navigation operation will be assessed by a technical salesperson depending on your facility’s layout and assembly requirements.

There are many different types of agv vehicles in use today.

An AGC is a basic AGV system with limited automation where it follows a painted strip on the floor to move along a pre-determined path to perform repetitive actions. AGV carts are often used in sorting, storage, and cross-docking applications to reduce labour costs.

These AGV transfer carts are designed to carry specific parts or products with custom tooling to carry a pallet or tote loaded with multiple items.

These heavy load AGV’s are used for transporting substantial cargo over longer distances within a large facility without the assistance of an operator, following a set path. This path can be altered simply by reorienting the floor tape or paint that the AGV follows.

Towing AGVs are automated guided vehicle robot carts designed to act as stock robots for warehousing, pulling orders from heights with forks or other special tooling created for the specific application.

A tugger AGV pulls heavy loads from point A to point B employing trailers filled with product or parts. These tugger automated guided vehicles can have several pre-determined stops while moving through a plant, factory, or warehouse

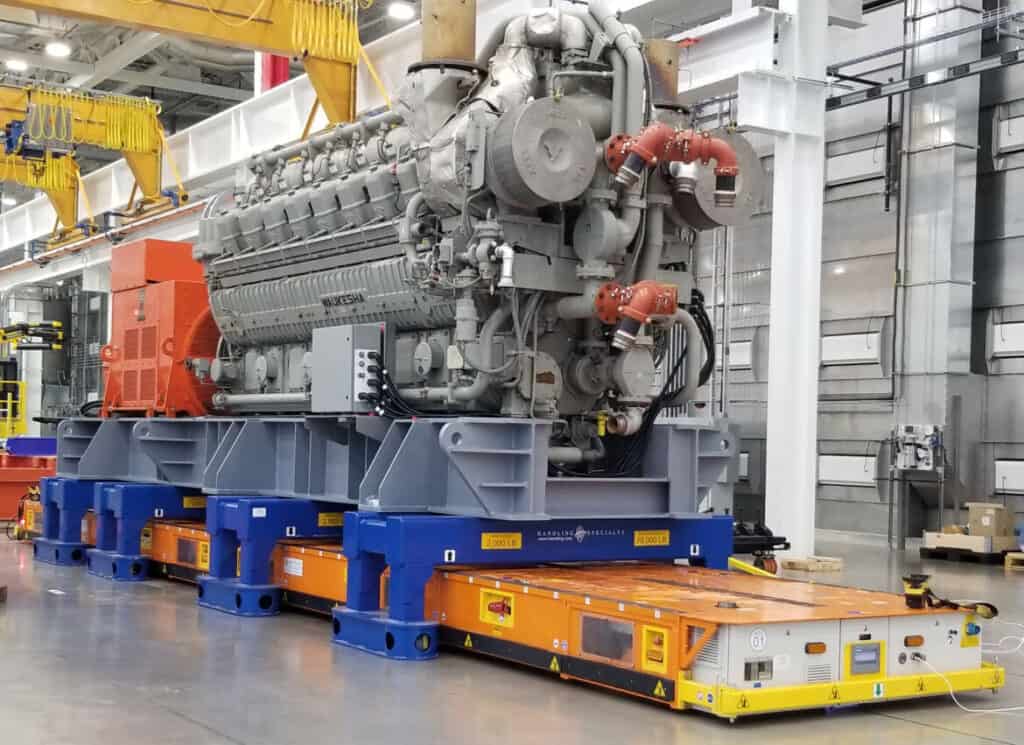

An industrial automated guided vehicle working principle is to withstand very heavy loads such as it would in Truck Outfitting assembly plants, which requires the AGVs to carry the frame through the assembly process. These AGV’s always require a custom design with tooling options to work with the assembly or manufacturing plant’s specific applications.

A custom design/manufacturing firm that has engineered the perfect AGV automated guided vehicle for various customers spread over many industries is a valuable discovery when first researching automation. The knowledge pool found within a company like this offers a client years of experience designing and building AGV systems for specific application requirements. A custom-heavy duty automated guided vehicle is the AGV of choice for assembly and manufacturing facilities. Engineered with robust components and with the harsh environments and punishing cycles within assembly plants top of mind, custom automatic guided vehicles are the industry choice.

Custom-tooling for your AGV system is also an important part of the application-specific design. Each product is different, and some assembly facilities will use the same AGV for more than one product, requiring several modified tooling accessories to move an item through the assembly process. Scissor lifts are also an excellent addition to an automated guided vehicle including the option of lifting and lowering the product to increase ergonomics at the work cell. Along with the AGV’s motion direction, speed, and timing, the scissor lift can be pre-programmed to raise and lower to a specific height at different work cells.

No longer are plc based automatic guided vehicles built to follow fixed tracks traditionally built into the floor of a facility to guide the vehicles, but rather magnetic tape that requires sensors or painted line followed by the AGV’s laser guidance system. Unlike tracks built into the floor, the tape allows for easy and affordable reconfiguration of the facility’s floor operations.

Other navigation controls for an AGV include gyroscopic, which use sensors to follow transponders embedded into the factory floor. Geoguidence works by the AGV’s system recognizing objects in its environment to establish its location in real-time, requiring no infrastructure.

LiDAR also requires no infrastructure, utilizing sensors that transmit laser pulses to measure the distance between the AGV and objects sharing its space. The data is collected to create a 360-degree map of the facility, allowing the AGV to navigate its route while avoiding obstacles.

Visual guidance is another option where cameras built into the AGV follow a path of features along its route. Once the unit is shown its path, it remembers the features and never forgets.

These navigation methods are available to any manufacturer of autonomous guided vehicles and should each be considered for their fit when discussing your AGV applications and floor layout requirements.

AGV systems have several drive motors to allow for specialized steering such as zero-radius turning, diagonal, left, right, backward, and forward movement, which offers extraordinary maneuverability within any factory space. AGVs are battery-operated, which also include a manual option for bringing the vehicle off the line for charging or maintenance tasks. They are usually fitted with motion stop sensors and kick stops for added safety. Each AGV is programmed to follow a pre-programmed course as well as obey speeds to further customize the client’s specific application and assembly needs.

An AGV system is designed with multiple safety features that offer exceptional traffic control within a facility through collision-avoidance capabilities using audible and visual alarms, motion sensors, E-Stops, and laser guidance. An automatic guided vehicle is an excellent addition to any busy operation in the manufacturing industry. Benefits include heightened safety, ergonomics, efficiency, and flexibility in floor layout design. An AGV can be built to hold and carry virtually any weight capacity, and with advancements in motion control, the AGV of the future is already here. Additionally, an automatic guided vehicle can be customized to any size to best fit an existing assembly floor layout and engineered to navigate narrow and low-lying areas where a traditional forklift would be rendered useless.

Industrial AGV systems are built for multiple industries, including automotive assembly, aerospace manufacturing, power generation, rail, food and steel processing, chemical, commercial printing, hospitals, paper mills, pharmaceutical, plastics, and warehousing and distribution facilities. All of these industries require application-specific material handling equipment to realize an efficient operation. AGV’s are the perfect vehicle to improve on existing material handling processes through their absolute ability to seamlessly integrate into an existing operation, improving the overall processes, or to become the driving design factor in a new, efficient assembly design.

The Maintenance & Repair portion of many industries also employee AGV systems. From traversing heavy wheel-sets along the vast corridors of a rail maintenance facility to running parts for an aviation repair shop, AGVs are a very adaptable product when designed for specific application solutions.

AGV’s offer exceptional accountability once a product is loaded onto an AGV, minimizing misplaced product. Where labour costs tend to increase and change quickly depending on multiple conditions, an AGV automated guided vehicle system’s costs can be very predictable, and its path changed as production and handling needs evolve.

Additionally, AGVs eliminate access issues created by conveyors and require less space than conventional forklifts, allowing for narrower aisles, increasing storage space within a facility. Battery charging & handling can be automatic with an AGV system, minimizing wear on components.

An automatic guided vehicle can also be fitted with IIoT industry 4.0 smart-technology, which allows the manufacturer and the facility operator to track each unit’s health in real-time. Operator control panels also assist in locating the unit within the facility, alerting when it requires charging, planned maintenance, and all through an advanced human-machine interface (HMI) screen. Transitioning from a preventative to predictive maintenance model is new to industry, and showing great results on the reliability of material handling equipment in the field. Knowing something is going to happen before it does, allows operators to bring an AGV off of the line and have it assessed by a technician, avoiding downtime before something serious takes the unit out of commission. To enable these remote monitoring capabilities, the unique requirements and challenges of industrial environments should be well understood by the equipment company you source your AGV design and build services.

Automated Guided Vehicles have smooth acceleration/deceleration, handling products gently, reducing product damage, perform repetitive movement tasks predictably, and because of their reliability, AGVs improve scheduling capabilities and the efficiency of operations while additional AGVs can be added to expand capacity and throughput in any assembly, manufacturing or warehousing operation.

The benefits to utilizing automation in material handling can not be overstated. Employee safety, product safety, and overall efficiency are met with an AGV automated guided vehicle for assembly and manufacturing applications. In these industries, you must rely on the expertise found at companies like Handling Specialty, which engineer and build AGV systems for multiple industries. Heavy-duty AGVs are a different animal than those which move product around Amazon and Walmart warehouses. AGVs for industry are custom-built from the ground up to function exactly to the customer’s needs. Whether moving product through the assembly process or assisting with parts distribution, and AGV in an industry setting is a very different piece of material handling equipment than one mass-produced to pick product from a warehouse. Understanding the difference is what will make your assembly processes excel over the competition. An automatic guided vehicle is an assembly operations greatest advocate of efficiency.

Never settle for a cookie-cutter version of a sensor-operated automated track-guided vehicle if your operation requires heavy product being traversed and lifted precisely for assembly processes. A company like Handling Specialty designs/builds AGVs and the heavy-duty material handling equipment that supports it. Personnel lifts, work lifts, four-post lifts, and other custom equipment can be designed and built by one company to realize your perfect factory floor. Turnkey design/build is the most effective way to engineer your industrial facility’s shop floor. Installation and training are part of the Handling Specialty experience, as are parts and services support long after the work is completed and your facility is producing.

There are multiple options to consider when discussing how you might best charge your AGV batteries. Wireless power transfer is an excellent and zero-maintenance way to charge your AGV battery, employing a sender and receiver coil transmitting up to 300KW.

Battery swapping is also a very efficient method and keeps downtime at an absolute minimum as a fully charged battery replaces the depleted battery the moment the AGV is running low. This can be performed manually or using an automated system. AGV batteries are not small and can be very heavy.

Automatic or opportunity charging can be done by plugging the AGV into a power outlet while it is in a static state, stopped to allow a technician time to work on the product, or at the end of a shift when the AGV is pulled off the line. An AGV can also be programmed to remove itself from the line (without interrupting the processes) and dock at a charging station.

Battery sizes and power levels would be decided upon during the design portion to ensure the AGV works to the customer’s specific application needs. How many batteries to purchase is another consideration as backup batteries offer even more security to an assembly operation.

For examples of an industrial AGV in application you can visit Handling Specialty’s YouTube pages and learn more about the AGV system on the website’s AGV Case Studies.