For most design firms, there are few things more inspiring than an engineering challenge. Underwater stage lifts are an excellent example of this.

The world of live entertainment is an exciting place where people and props come together to tell a story. Sometimes, those people and props find themselves surrounded by water, and more often than not, both will be submerged at some point during the performance. Because of this, the safety aspects of moving equipment must be heightened along with the obvious engineering challenges that accompany steel, hydraulics and electrical conduits operating in an underwater environment.

Royal Caribbean Cruise line’s custom-design aqua theatre, the Franco Dragone City of Dreams theatre (which took underwater stage lifts to a new height with their seamless scene shifts and massive pool), and Cirque Du Soleil’s “O” show in Las Vegas a shared vision of live theatre in, on, and around water.

The “O” show stage systems were 2.5 years in the making and designed to be a turn-key project. Handling Specialty Ltd. stepped up to deliver what the renowned theatre company asked for an underwater stage lifting system with multiple moving parts. The stage is essentially a pool containing 1.5 million gallons of water, where four hydraulically-actuated lifts raise and lower the four-piece stage, which measures 3,650 square feet.

The Franco Dragone Entertainment Group’s The House of Dancing Water in Macau, China, built a similar project. The 2,000-seat venue features a 270-degree theatre-in-the-round, housing the world’s largest commercial pool, which is 160 feet in diameter, 26 feet deep and holds 3.7 million gallons of water. With eight platform stage lifts, each capable of vertical travel of 27 feet (26 ft. underwater and 1 foot above water to create a solid, dry floor), the total platform area is 6,441 sq. feet. The stage’s dynamic capacity is 322,000 pounds, with a static capacity of 805,000 lbs.

The stage system also includes three vomitory lifts that travel 3.3 feet below water and rise 3.3 feet above the water (to accommodate props and performers). The total area of 1,056 sq. feet allows for a dynamic capacity of 52,800 lbs and a static capacity of 132,000 pounds. Six hydraulic power units are used to actuate the lifts, which move at a maximum speed of 20 feet per minute. Engineers included an electronic controls system, which enables the lifts to move independently or in synchronization.

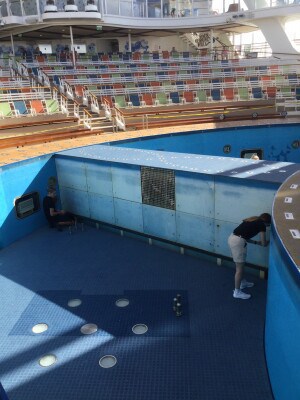

The Royal Caribbean Aquatheatre, which includes three underwater lifts, two diving board tilters, and one trampoline rotator, is another engineering marvel. Because this theatre is on a moving ship, multiple considerations for the motion had to be made to slow the movement of water from side to side within the pool. The runway lift features a vertically telescoping platform with a capacity of 10,000 lbs and can withstand an average of 10-kilopascal horizontal “sloshing load.” The total capacity of the underwater lifts is 90,000 lbs., covering an area of approximately 1,000 sq. feet, with 176” vertical travel. The stage area is perforated with about 432,000 holes to ensure minimum water displacement as the lifts move up and down. The stage lifts are hydraulically operated with non-toxic water glycol fluid. To date, there are five ships on the sea, with an Aquatheatre and another on the way.

Designing a system to move people and props vertically and horizontally on a theatre stage is one thing. Putting that stage underwater is an entirely different story that demands an experienced Custom material handling company to work intimately with each customer to assist in animating their vision. Hundreds of hours from technical sales to design/engineering to project management, manufacturing, installation, testing, and support keep shows running and operating to schedule.

Handling Specialty’s electrical designers, mechanical engineers, mechanical designers, millwrights, electricians, assembly technicians, service controls specialists, and project managers all play integral roles in realizing the end product. Writing original code and building control panels in-house allows everything to be done under a single banner, ensuring quality and efficiency. Trial and error have been excellent teachers over the many years Handling Specialty has been designing and building material handling equipment and have taught our engineering department many valuable lessons, which are employed each time a new product is imagined.

The incredible array of technology included in these projects requires square footage with entire rooms dedicated to the pumps and hydraulics, and a control room, running each lift between performers moving in and out of the water.