Pit Mounted Four Post Lift for Jet Engine Assembly

Overview Handling Specialty custom engineered and manufactured six (6) pit-mounted four post assembly stations for a major airplane engine manufacturer. The customer required that the lifts could not be visible above floor level at any time and had to provide smooth, synchronized, level lifting through the entire range of travel to prevent jarring of the […]

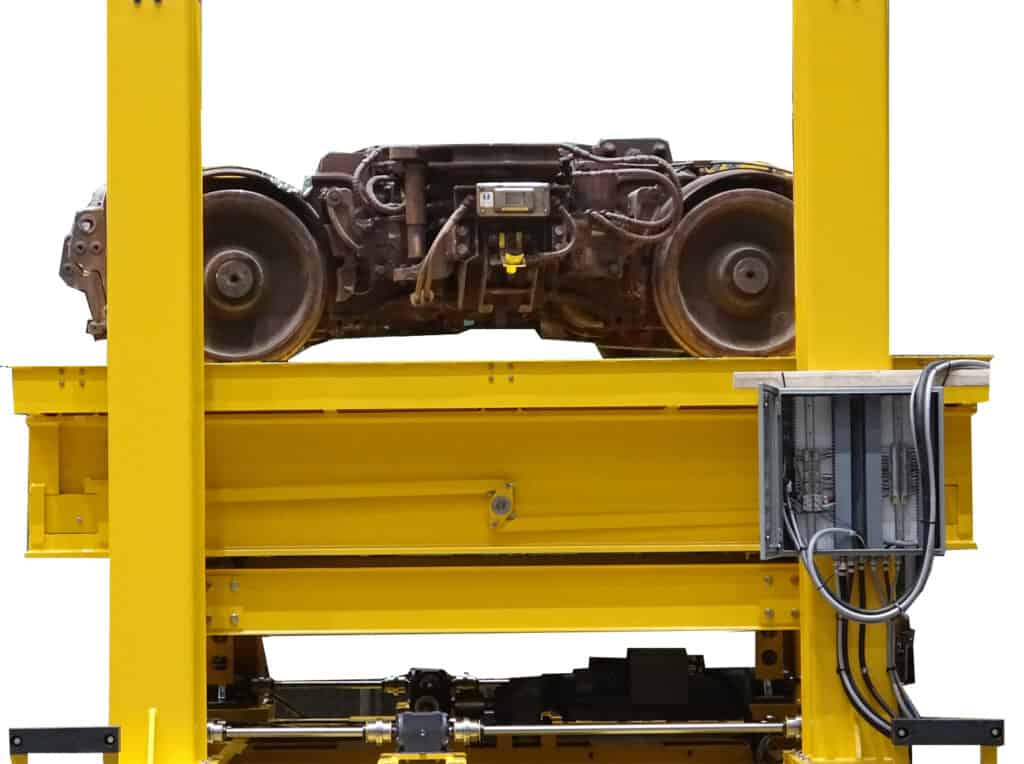

Heavy Duty 60 Ton Capacity Shim Table for Locomotives

Overview Handling Specialty Manufacturing was successful in its bid to manufacture a 60-ton locomotive shim table for CP Rail in Winnipeg, Manitoba. Shim tables are used to lift and hold a locomotive so rail technicians can shim or “true” the wheels. The lift is installed in a pit in the maintenance building. The lift is […]

10 Ton Drop Tables for Rail Maintenance

Overview These 10-ton Drop Tables for rail maintenance travel below the railcars to remove and replace wheelsets. The body supports lift the train car at its lifting pads, allowing technicians to loosen the wheelsets while the bogies rest on the drop table service top. Then the drop table lowers the wheelsets and moves them along […]

Heavy Duty Drop Tables for Rail Maintenance

Overview The Double Drop Table is a fully engineered mobile hoist system that will facilitate the replacement of an existing rail car wheelset with a new wheelset. The Double Drop Tables traverse on a set of rails laid perpendicularly and below the elevation of the rail car service tracks in a trench of prescribed depth. […]

50 Ton Drop Table

Overview A large railroad maintenance facility in the United States required a 50-ton drop table to facilitate the changeout of traction motors on its locomotives. Handling Specialty custom engineered and designed a 50-ton drop table based on an original heavy-duty Whiting Corporation design. Whiting pioneered the development of the drop table concept. Wheelset changeouts are […]