Custom Scissor Lift with Rotator

Overview This Custom Scissor Lift with Rotator will be used to stack zinc plates in a smelting process. Built with heavy-duty steel to withstand the rigours of a smelting operation, the lifts include the rotator on top of the platform. These lifts will run 129 cycles/hour, 24 hours a day, 310 days a year. Features […]

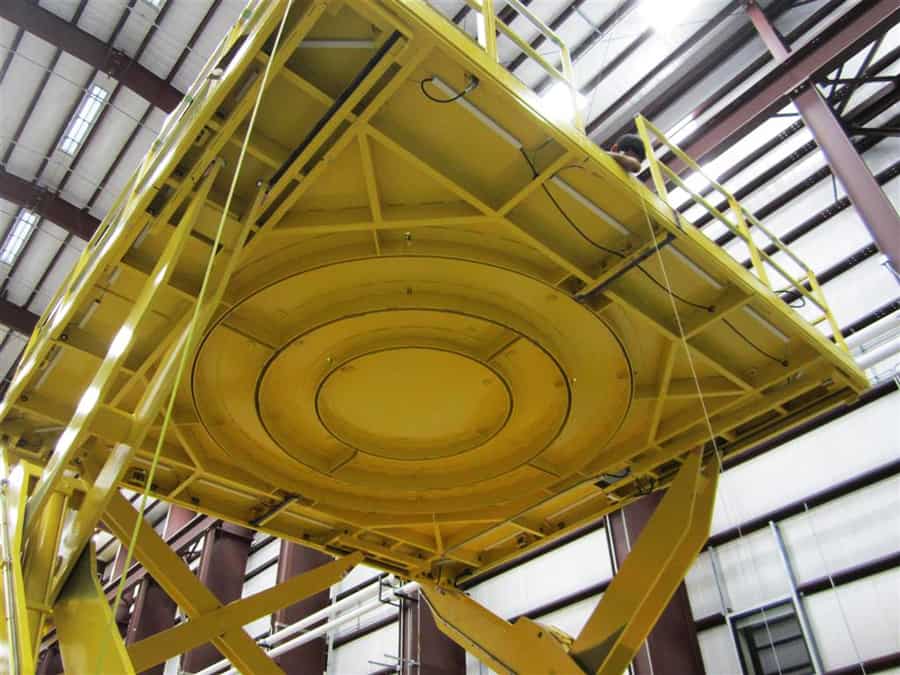

Paint Booth Lift for 85,000 Lb Gas Compressor

Overview An Ohio-based gas compressor manufacturer engaged Handling Specialty to design and manufacture a high-capacity hydraulic lift to be used during the painting process. Because some of their compressors have centers of gravity outside the lift envelope, Handling Specialty engineered a custom solution specifically for this application. In addition to the offset loads, the underside […]

Hydraulic Lift for Nuclear Industry

Overview Handling Specialty and Atomic Energy of Canada combined forces in the design and manufacture of a lift system used to service AEC gimbles. The gimble is a device that is mounted to an overhead crane in the reactor tube area of a nuclear power plant. Positioned on the underside of the crane, the gimble […]

Multi Stage Scissor Lift for Turbine Assembly

Overview Handling Specialty was asked to quote on a vertical assembly platform that is being used during the assembly process for large energy turbines. The lift is mounted in a pit and rises approximately 35 feet, safely holding personnel and equipment as the turbine assembly is completed. The platform features 3 (three) round removable plates, […]

4-Stage Hydraulic Lift

Overview With a lifting capacity of 12,000 lbs. and a fully raised height of 49 feet, this four-stage hydraulic scissor lift was custom designed for a very specific application at a missile defence test complex. The unit has a lowered height of just eight feet.

Custom Scissor Lift with Tilter for Jet Wing Assembly

Overview Handling Specialty worked with Lockheed Martin, a major aerospace/defence company in the US, to custom engineer and manufacture a material handling system that would move highly sophisticated wing assemblies for the F-35 Joint Strike Fighter along an assembly line in their Fort Worth, Texas facility. One part of this system is the transport dolly. […]