Industrial Mechanical Scissor Lifts

Overview

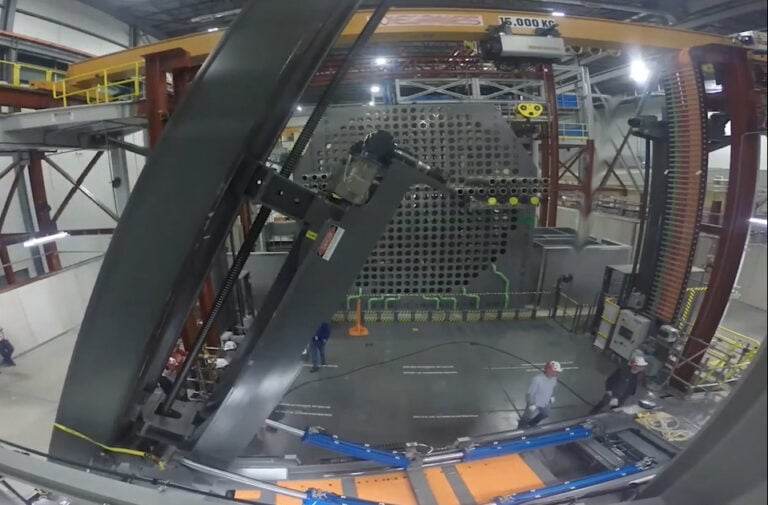

Mechanical scissor lifts can come in single or multi-stage lifting capacity. To reach higher heights, you want a multi-stage scissor lift. Mechanical scissor lifts can withstand enormous loads and weights and raise and lower those loads safely and ergonomically. Every industry involved in manufacturing has a place for mechanical scissor lifts in their operations.

What is a Scissor Lift Mechanism?

Industrial scissor lifts are built to withstand the rigours of continuous cycles in the most demanding environments. A custom mechanical lift can be engineered to any shape, size and capacity. The scissor lift mechanism comprises connected parallelograms with hinged pivot-point intersections. This allows the operator to elongate or contract the mechanism – making it rise or lower, to position the product at specific heights.

These mechanisms can be single-stage or multi-stage, depending on the height you want to raise the product. Fall-safe precautions and limit switch sensors are built into the mechanical scissor lift.

What are the advantages of an industrial scissor lift?

The advantages of an industrial scissor lift are numerous. Ergonomics, efficiency, reliability, and quality are all engineered into Handling Specialty’s mechanical scissor lifts. These can be designed as single-stage scissor lifts or multi-stage scissor lifts for multiple applications such as assembly, manufacturing, and MRO operations. They are found in virtually every industry, from Aerospace to Automotive and Entertainment.

Canada - INNIO