Planned Maintenance

Planned Maintenance

Following the inspection visit, the information gathered will be documented, analyzed and submitted in a written report in a timely manner.

Planned Maintenance

The Handling Specialty maintenance program provides you with the opportunity to take advantage of the following benefits

- Reduced unplanned equipment downtime.

- Proactive approach for predicting problems/failures and remedy during planned maintenance.

- Impartial review of your maintenance and production practices.

- Direct contact with Handling Specialty skilled service technicians and their many years of knowledge.

- Additional assistance from our engineering department.

- During the three year contract period, all parts purchased will be discounted by 5%.

Scope of services

- All work stations will be visually inspected. A detailed checklist will be used to ensure that all critical components are checked and values recorded for wear tracking.

- Adjustments and/or notation of critical items that require immediate attention will be completed.

- All components requiring lubrication will be lubricated.

- Discussion with your maintenance and operation personnel will be held for any input regarding equipment performance and possible improvements to the system will be noted.

- Review of any component failure to determine if further follow–up is required.

- We will review any preventative maintenance records for trends, and pinpoint areas of opportunity. We will assess whether the PM’s are being completed and whether changes to the PM program should be made.

- Provide feedback on any past visits, and changes made.

- At the end of the inspection visit, a close-out meeting will be held to offer a summary of recommendations, concerns and procedures that are being done right to maintain the equipment in optimum operational condition.

Following the inspection visit, the information gathered will be documented, analyzed and submitted in a written report in a timely manner. This report will include the following feedback on your equipment

- Review the performance and the condition of your equipment.

- Identify and explain any outstanding deficiencies and possible areas of improvement. These will be prioritized according to impact on production.

- Project future major problem areas and estimated life of worn or damaged components.

- Provide comparison to the performance of other similar Handling Specialty installations.

- Provide information on component and service costing as required.

- Identify any areas where additional training would be beneficial.

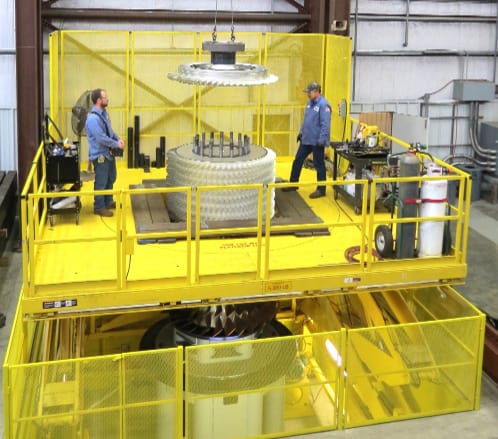

The Handling Specialty team was good to work with and very responsive to all concerns. I enjoyed working with your team. Always satisfied.

Terry GreatheadABB Inc.

I have honestly never dealt with a supplier more professional and more dedicated. Even with all the changes we asked, you managed to deliver the finished product a week ahead of schedule, and in the near future, we might get more of these platforms.

Christophe Malek Siemens

The step by step approach to assist us was excellent. The Product Quality exceeded our aspirations and fit exactly the scope we required. Excellent installation and on-site training. A very professional Company with excellent communication and Customer satisfaction delivered.

Peter Bray Electro-Motive Diesel Limited

Handling Specialty did a brilliant job to make this amazing, one-of-a-kind production a huge success! Fabrication and installation of eight hydraulic lifts in a 3.7 million gallon swimming pool for a purpose built, 2,000 seat water spectacular venue in Macau.

Dawn Chiang Project ManagerThe House of Dancing Water Theatre Projects

I have honestly never dealt with a supplier more professional and more dedicated. Even with all the changes we asked, you managed to deliver the finished product a week ahead of schedule, and in the near future, we might get more of these platforms.

Christophe Malek Siemens

Gallery

or contact us directly by calling toll free 800-559-8366