Custom Work Positioners

Custom Work Positioners

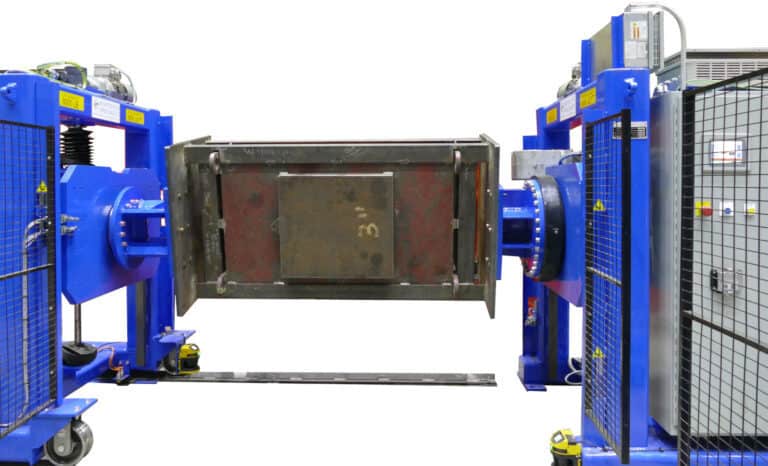

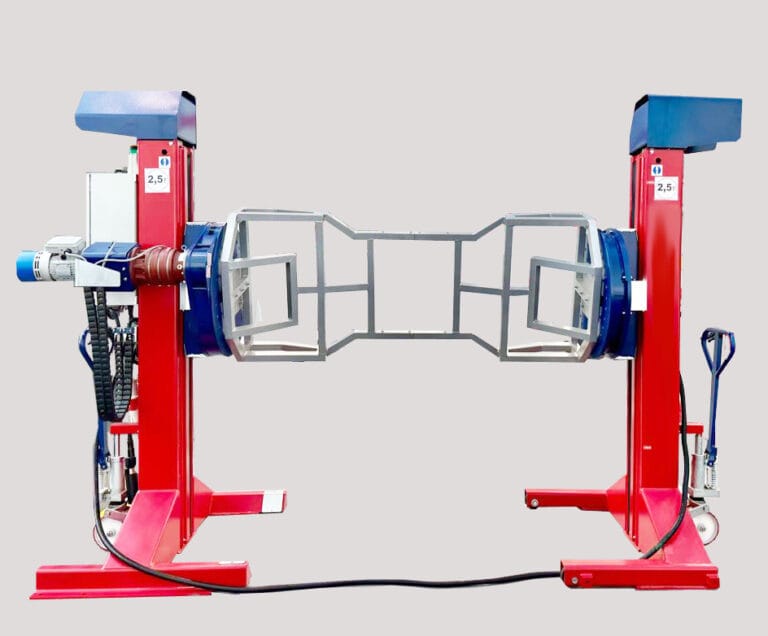

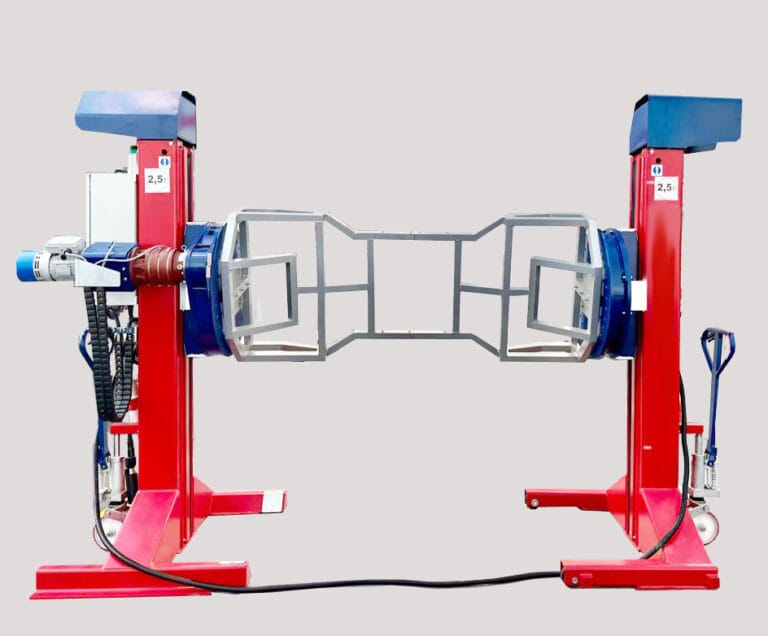

Custom Solutions for your Parts Positioning needs. Head Stock-Tail Stock, Rollover Work Positioners.

Improve your facility’s weld positioning, inspection, assembly and maintenance operations.

A crucial part of any manual or robotic welding operation is how the part is positioned. Our rollover stations can be easily integrated into your existing system or assembly line to help optimize your processes and procedures.

Why Employ a Head Stock/Tail Stock Work Positioner?

Designed for the assembly, material handling and welding applications industries, Headstock and tailstock elevating and tilt work positioners can be customized to fit your facility’s requirements, including fixed‐fixed, fixed‐adjustable, fixed‐mobile, and fully portable positioner options.

- A headstock/tailstock spins on both the vertical and horizontal axis.

- Rotating about the horizontal axis – coupled with a custom fixture design – a rollover for material handling provides clear access to the top, bottom, front and back of the part.

- In a welding application, welds are presented to the operator with optimal weld positioning, torch access, and torch angles, resulting in improved quality when using the material handling rotisserie.

- A work positioner will translate vertical position welds to an optimal flat or horizontal position.

- In all applications [inspection, assembly, cleaning, etc.], the part is rotated into the worker envelope, reducing ergonomic fatigue and increasing productivity and up-time as the welding positioner offers optimal usability.

Positioner Benefits.

A properly positioned weldment, regardless of the size, reduces welder fatigue, increases safety, improves weld quality, and saves on production floor space. Workers are not forced into an unsafe or ergonomically uncomfortable position by relocating the weldment or assembly component.

Applications

- Heavy Welding Industry

- Robotic Welding, cutting and Assembly

- Production Welding

- Laser Applications [Welding, Cutting]

- Component Assembly

- Cleaning

Gallery