Overview

Handling Specialty was approached by a current customer to engineer and manufacture a custom equipment solution for one of its rail clients. The client needed a safe and cost-effective equipment solution to position rail personnel on continuous welded rail cars (Open rail cars that carry long, continuous lengths of rail). These cars carry the lengths of rail that are used during the laying of new continuous weld track.

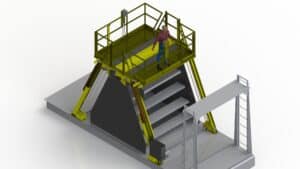

The customer asked Handling Specialty to engineer a very safe, ergonomic lift system that straddles the stacked rail, where workers bolt the lengths of rail after it has been laid on each level of the tie-down rack. The lift is also used during the unloading of the rail off the railcars.

Features

- Lift capacity (each platform) 500 lbs.

- Hollow steel structural frame with two personnel platforms.

- Electrical motor driven, chain drives with a safety pawl.

- Operator platform with safety handrail, kick plate, and swing close gates.

- The platform contains button box controls.

- Both sides of the lift platform operate in tandem.