Overview

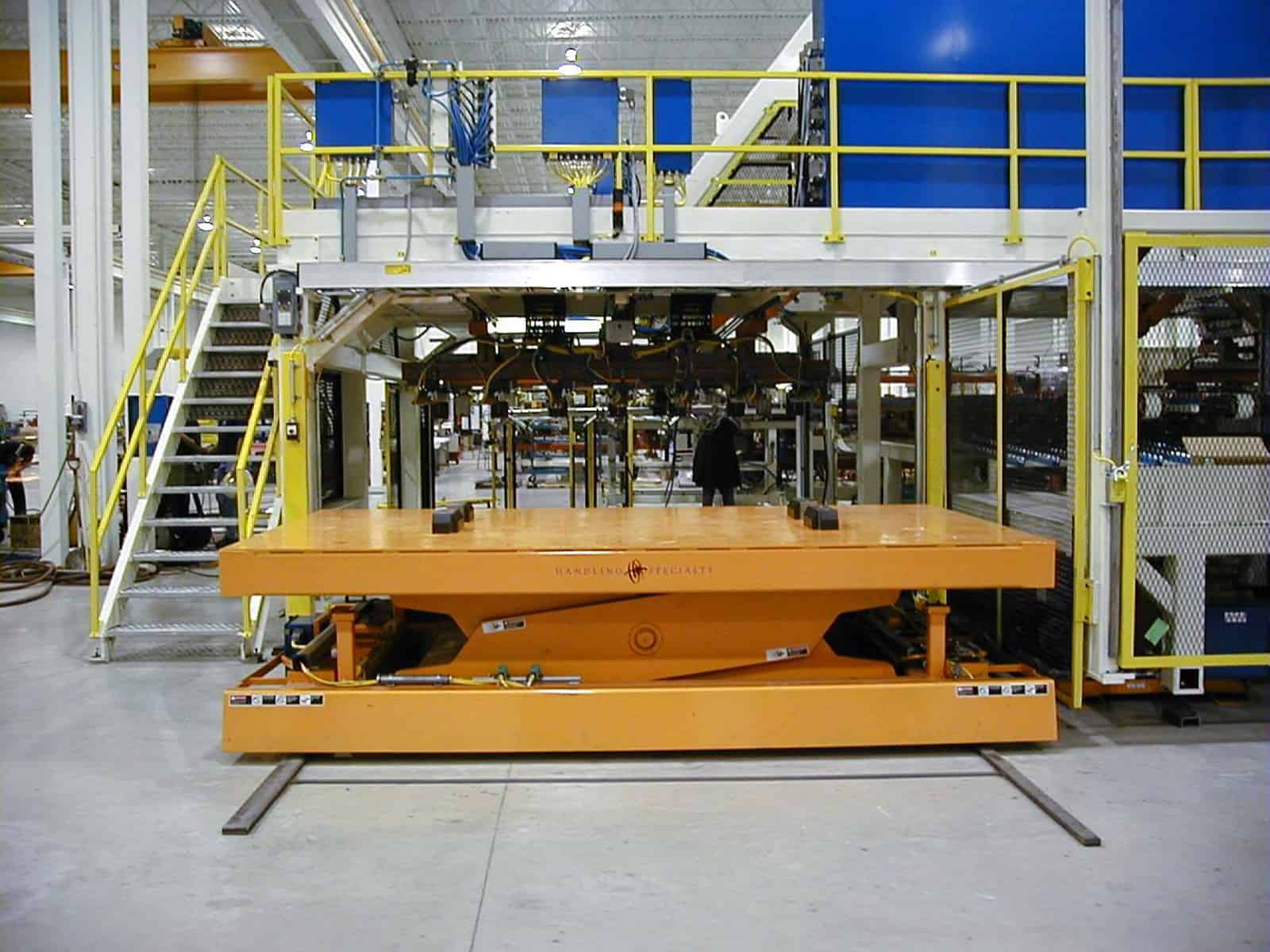

Handling Specialty custom designed and manufactured many steel blank destacking lifts that are used to continuously feed automotive stamping plant presses. Pictured in this Solution Story are two self-propelled lifts that were custom engineered and manufactured by Handling Specialty to meet the customer’s specific requirements.

The lifts are durable and robust and are required to work continuously 24 hours a day, 7 days a week. To ensure the stamping press never runs out of blanks, this system ensures that while one lift is in the station indexing precisely, the second lift is being reloaded with blanks. As soon as the last blank is removed, the entire system shuttles over, and the feeding operation resumes. The empty table is then reloaded while production continues without stopping.

Features

- Tandem lifts for virtually continuous feeding.

- Electro-mechanical drive system provides traversing motion along rail guides.