Overview

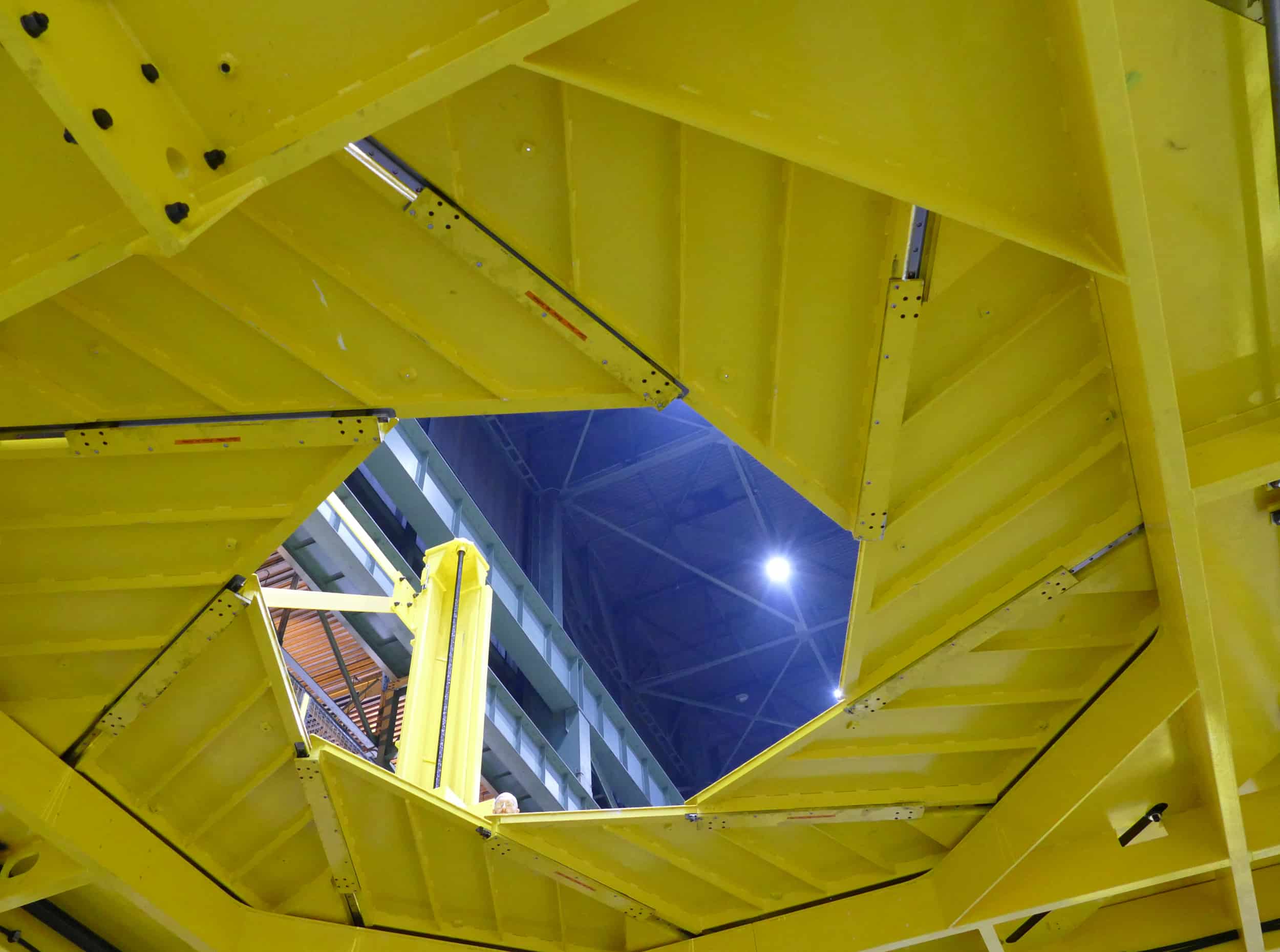

This custom-designed vertical assembly platform will be used to position technicians at the correct elevation and location during the build of large turbines. The assembly’s unique iris opening allows for exceptional placement around the diameter of the product to build the turbine out.

Features

Raising and lowering the platform and stair assembly is actuated via four ballscrews placed at each corner post driven by powerful motors, each mechanically synchronized with one another. The central iris opening actuation is hydraulic.

The articulating staircase makes accessing the platform at any height simple and safe. When the platform is fully raised, the staircase assumes a comfortable 47-degree pitch.

The operator control panel is located on the platform enabling technicians easy access to alter height and width while working. The vertical assembly platform is surrounded by 90.5” high guarding with graphite black mesh mounted to the floor. The same guarding lines the platform itself. Locking mechanisms on the guarding’s sliding door offers an increased opportunity for safety while work is being done at heights. Fall-safe switches and limit switches also work to keep employees and product safe from harm.

As with all of Handling Specialty’s four-post lifts, this custom vertical assembly platform can be repositioned on the facility’s floor as the floor plan changes over time.

Are you interested in promoting your assembly or manufacturing facility’s efficiency and ergonomics? Of course, you are! Handling Specialty will custom design the solution for your specific application.

Contact us today to discuss your unique challenges.