Overview

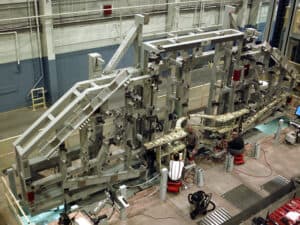

When faced with the challenge of producing up to 22 planes per month for the F-35 Joint Strike Fighter Program, Lockheed Martin selected Handling Specialty based on our expertise in the automotive and aerospace industries.

Vertical assembly stations are typically a four-post, screw-driven lift design with a platform that has a customized opening which allows access to the product from all sides and elevations. The mechanical automation ensures smooth, synchronized and level motion throughout the range of travel with secure load holding at any elevation.

Features

- Four post, screw-driven lift design with a platform that has a customized opening to the aircraft’s wing allows access to the product from all sides and at all elevations.

- Platform travel speed is configurable between 0 and 10 fpm.

- Smooth, synchronized and level motion throughout the range of travel with secure load holding at any elevation.

- The platform opening is off-center and has sliders on both sides with removable guard rails to allow personnel to move close to the wing (sliders must be fully retracted for the platform to move vertically).

- Non-slip, fire-resistant plywood deck, fluorescent lighting system, fire suppression system.

- Utilities accessible from the platform include electrical quick-connect pneumatic ports, computer data ports, and a vacuum system.