Overview

Handling Specialty’s experience in transformer assembly was adopted by ASEA Brown Boveri’s American and Canadian plants for their electrical transformers.

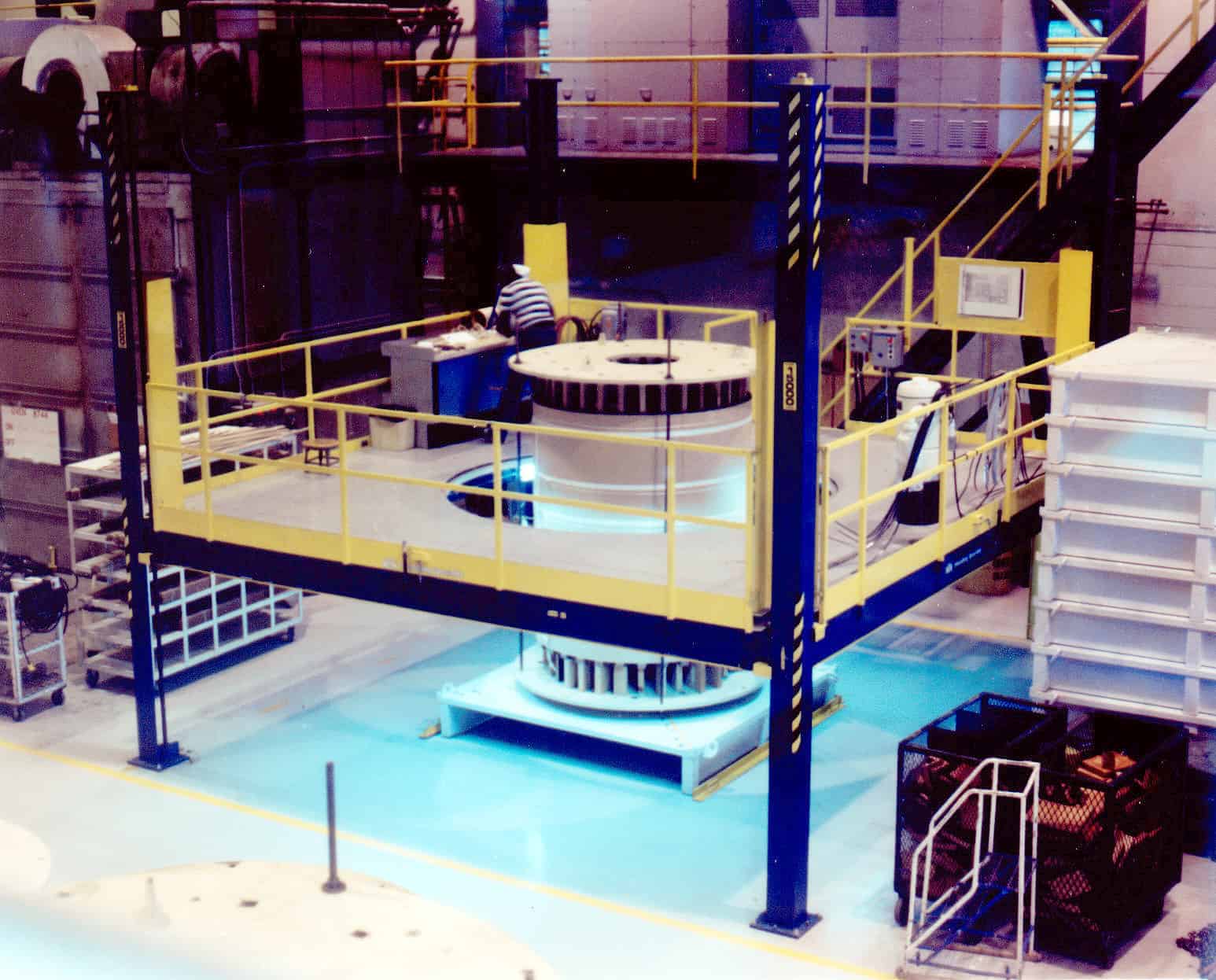

One of the steps in the assembly of large transformers is the winding of wire around the central coil. Coil winding is done vertically. A moving work platform allows employees to position themselves at various heights as the transformer is vertically built up with a coil. The unique design of Handling Specialty’s Cargovator is suited ideally to this task.

The CargoVator uses a self-locking Acme screw jack system. Four screw drives are located at each corner of the lift and mechanically linked through the platform to ensure perfect synchronization. Safety features, as well as platform size (up to 1,000 square feet), are customized to suit each transformer application.

Features

- Four post lift with mechanical actuation.

- Stable, level lifting platform with zero creep.

- Combines work platform and moving mezzanine.

- Electro-mechanical drive with machine screw actuators.

- 100% level lifting.