Overview

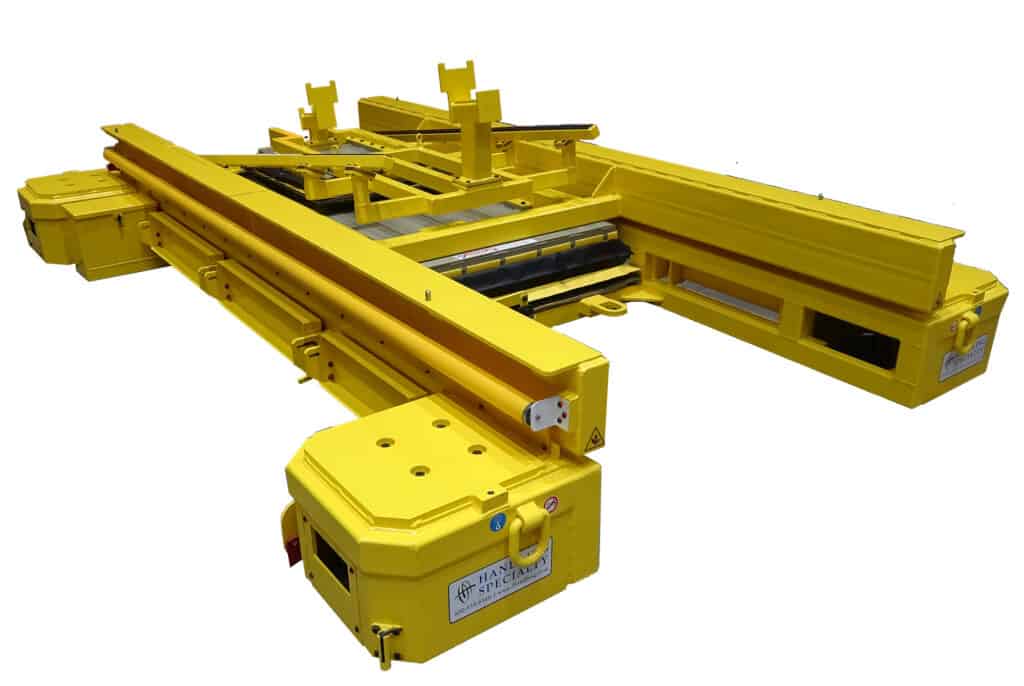

Handling Specialty was approached by the technical division of a large US automaker to custom engineer a lift that could be integrated into different conveying systems. The company created an innovative solution that involved combining an overhead crane and a scissor lift. The crane moves in an “x-y” direction while the scissor lift operates in a “z” motion. This allowed the automaker’s technical team to examine various ergonomic situations.

The lift system is mounted onto an overhead crane that can lower, raise or suspend at any point for an indefinite period. Zero load creep was satisfied using a self-locking Acme screw drive. The load sway typically associated with cable winch lifting was eliminated due to the more effective use of scissor geometry.

Features

- Inverted, custom-engineered scissor lift.

- Mechanical screw actuated lift.

- Precise vertical and horizontal positioning.

- Clean non-hydraulic drive system.