Overview

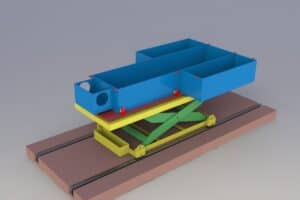

Handling Specialty was approached by a transit organization in Canada to design and manufacture a Custom material handling solution to assist technicians in removing and re-installing a large metal housing (containing electronics) weighing up to 4,500 lbs from the underside of Siemens transit vehicles.

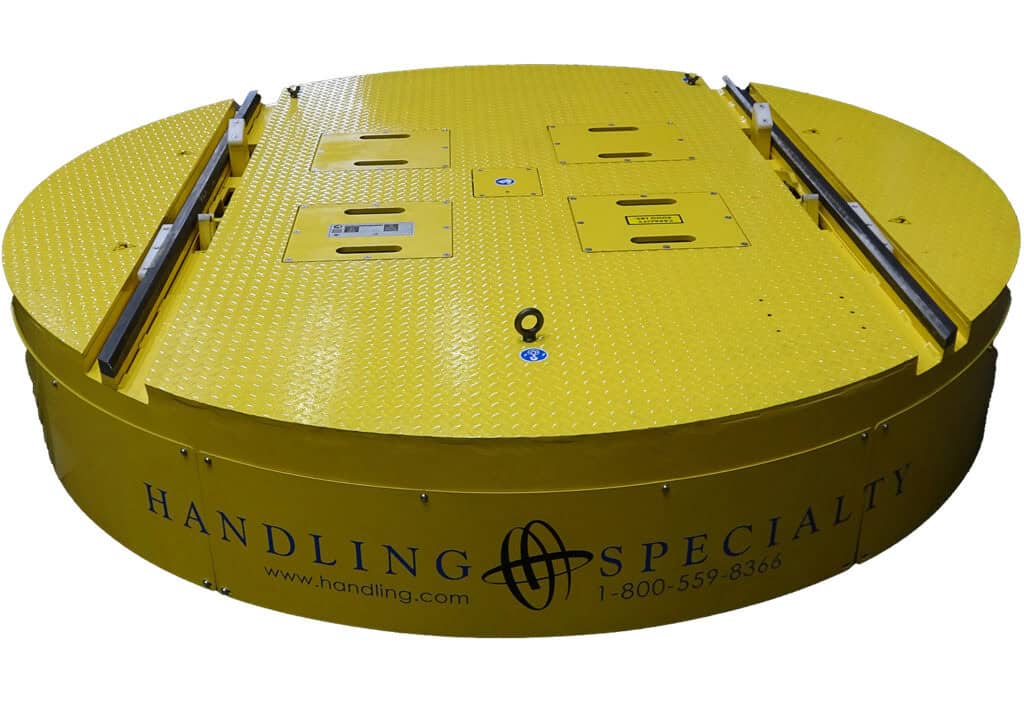

A wobble plate was installed on top of the lift because the metal housing requires manipulation during the re-installation process, and the wobble plate allows movement 1″ horizontally in all four directions.

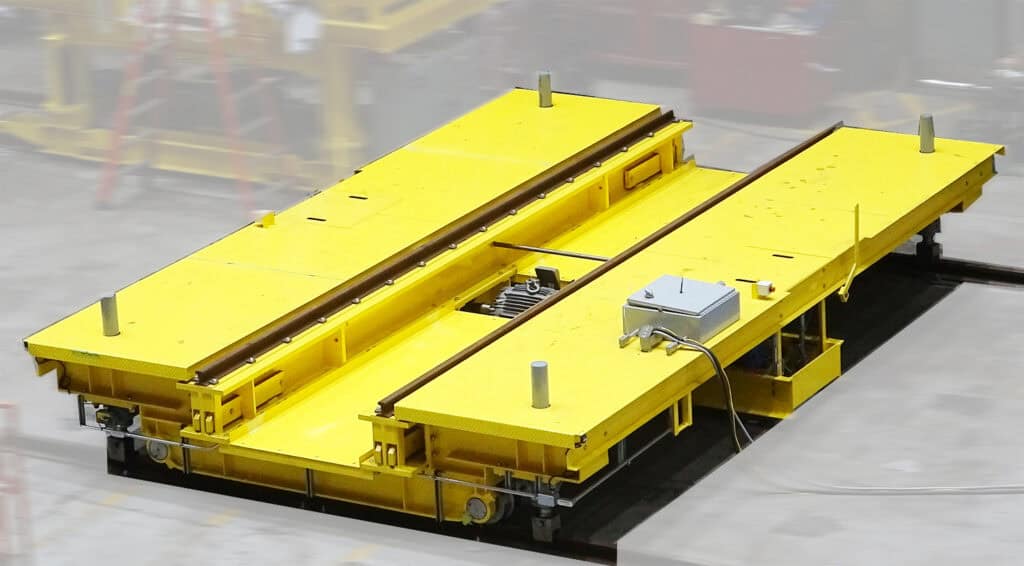

In terms of positioning the lift, it is manually pushed under the transit vehicles via a set of steel flanged wheels designed to move on a 56 1/2″ standard gauge track. This material handling solution could also be motorized or self-propelled and could also be engineered to remove trucks (bogies), DMU engines etc.

Features

- Lift equipped with top wobble plate allowing ±1″ of horizontal adjustment (additional flexibility to remove and install equipment on the underside of vehicles) on all four sides.

- Wobble plate set on ball roller transfers and includes heavy-duty plastic guides on corners for flexibility.

- It is operated by a hand-held pendant.

- Includes various safety features.