The Engineering Marvel Behind Heavy-Duty Handling Solutions for Aerospace Companies

Aerospace material handling equipment demands specially engineered solutions to manage heavy loads and delicate movements while adhering to strict industry safety regulations. Handling Specialty’s custom-designed scissor lift is a testament to our commitment to safety, with a perfect blend of robust design and safety features.

Unique Challenges in Aerospace Equipment Handling

Moving heavy and complex machines like jet engines safely comes with many challenges:

- Weight Distribution: Jet engines are very heavy and cumbersome. To lift and move them safely, we need special tools, such as AGVs and four-post lifts.

- Precision is key when moving these engines in a confined space like a test cell. At Handling Specialty, we understand the importance of precision in preventing bumps or crashes, and our solutions are designed with this in mind.

- Safety: The jet engine test cell can be dangerous. All tooling used must be customized for the engine being assembled.

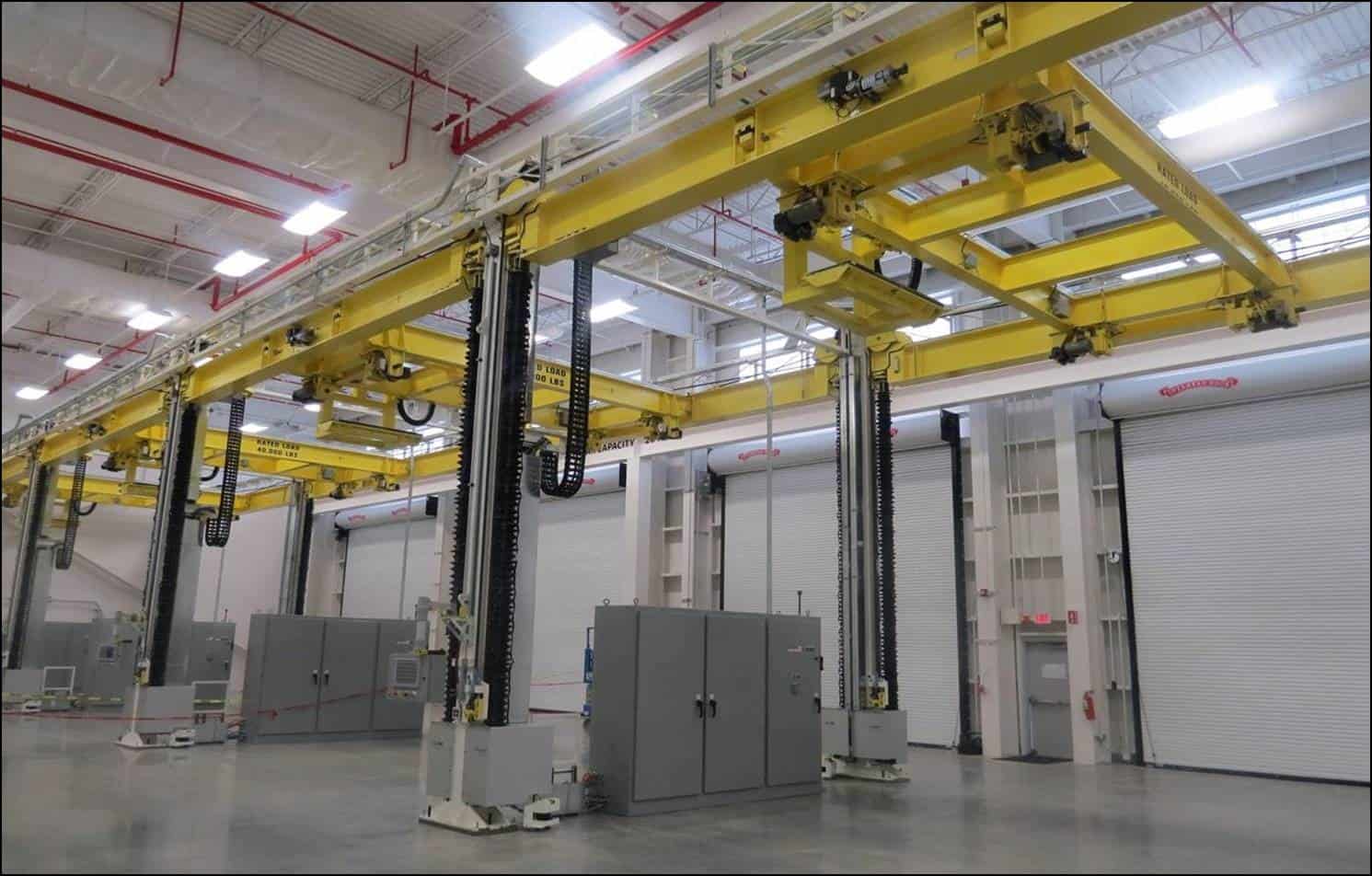

Designing a Custom-Engineered 4-Post Lift for Aerospace Needs

Handling Specialty built a four-post lift to receive a jet engine, rotate it 360 degrees, raise, lower, and tilt the unit for inspection, assembly, and maintenance processes. The heavy customization of the four-post lift helped them meet the specific needs of the aerospace company and manage jet engine handling effectively. This design keeps the workers and equipment safe with ergonomic engineering.

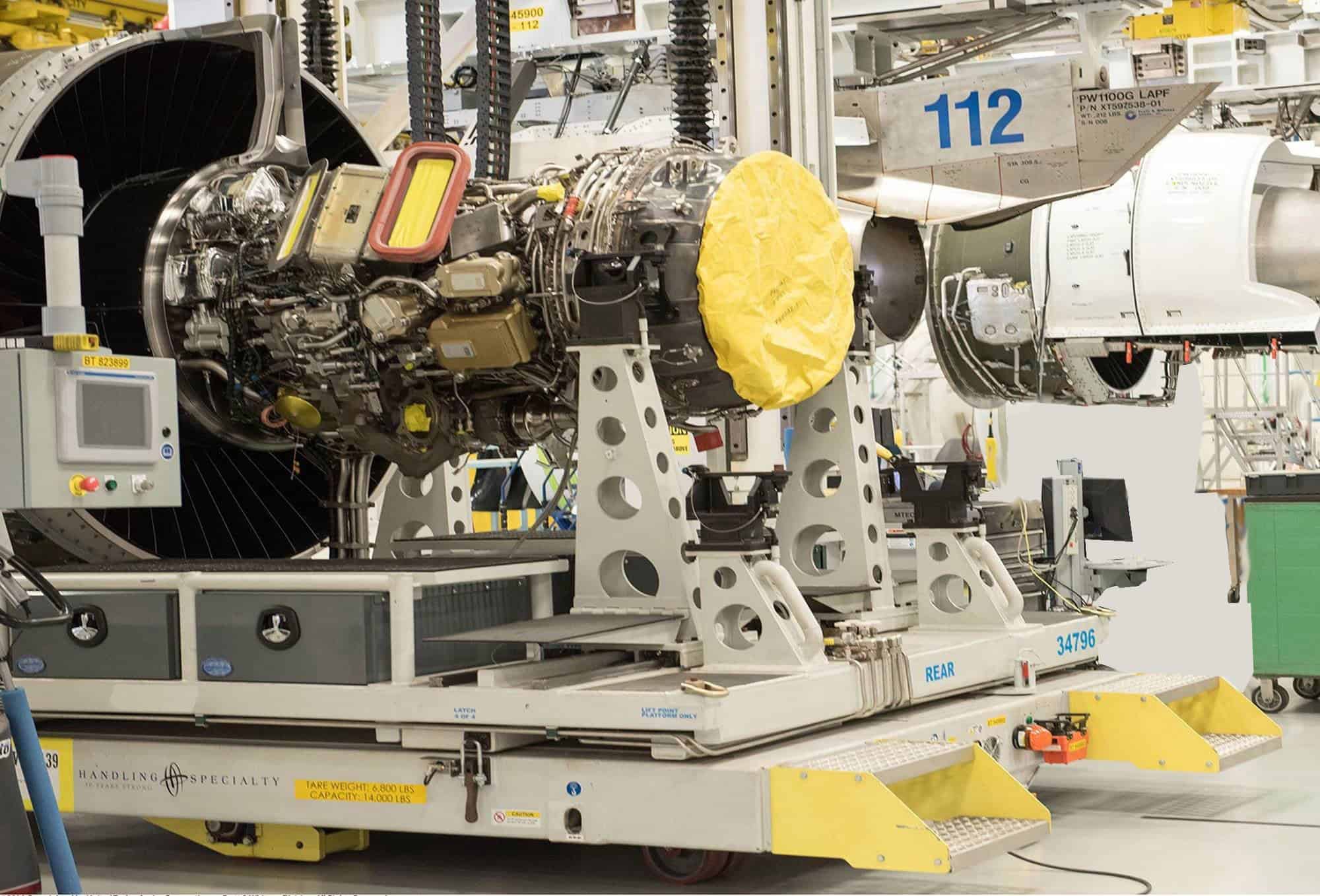

Designing a Custom-Engineered AGV for Aerospace Needs

Automated Guided Vehicles (AGVs) and manually guided vehicles (MGVs) offer a custom solution for moving products through an aerospace facility’s assembly, testing, or maintenance processes. More robust and flexible than traditional forklifts, AGVs and MGVs can be explicitly designed for the facility. They include custom tooling and features like rotating platforms, scissor lifts, turn tables, and other essential upgrades to suit any aerospace production line. AGVs typically move jet engines through an assembly or testing line where they can be programmed to stop and start in a predetermined schedule.

Handling Specialty’s AGVs are designed with safety as a top priority. They are equipped with audible and visual alarms, sensors, laser guidance, and other features to ensure reliable and safe material handling in the aerospace industry. This commitment to safety makes AGVs some of the most trusted assets in the business.

Conclusion

In conclusion, Handling Specialty smartly designs aerospace heavy-duty custom handling solutions for the specific needs of moving aerospace equipment like jet engines in an assembly, testing, and MRO process. It includes adding AGVs and 4-post lifts that work together to ensure precise positioning and movement through work cells. These custom-made solutions provide stability and accuracy when lifting heavy loads. Handling Specialty designs makes them safer in challenging aerospace settings. These solutions deliver outstanding performance and dependability for different aerospace tasks. To discuss your heavy-duty equipment handling needs, you can contact us here.