Heavy-Duty Railway Turntables: Essential for Locomotive & Rail Car Maneuvering

Introduction: The Unsung Hero of Rail Operations

It goes without saying that efficiency, safety, and precision are paramount in the rail industry. While locomotives and the vast network of tracks often capture attention, there are critical pieces of infrastructure that work tirelessly behind the scenes, enabling the seamless movement of these heavy assets. Among these vital components, the heavy-duty railway turntable stands out as an unsung hero. These robust machines are indispensable for navigating the intricate pathways of rail yards, facilitating maintenance, and optimizing operational flow. As the global railway equipment market continues its steady growth, projected to reach USD 250 billion by 2033 [Railway Equipment Market, 2026], the importance of specialized equipment like heavy-duty turntables becomes increasingly evident. This article delves into the essential role, engineering marvels, operational benefits, and practical considerations surrounding these indispensable pieces of industrial machinery.

Setting the Scene: The Immense Challenge of Maneuvering Heavy Rail Assets

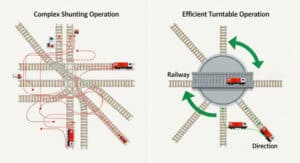

A comparison of a traditional, complex shunting operation versus the streamlined process of using a heavy-duty railway turntable to change a locomotive’s direction.

Maneuvering locomotives and long rail cars within a confined railyard present a significant logistical challenge. Unlike road vehicles, rail cars are restricted to tracks and cannot easily change direction without extensive track switching. Complex shunting operations, involving numerous points and signals, are not only time-consuming but also increase the risk of accidents. Positioning a locomotive to face a different direction, or moving a rail car between diverging tracks that don’t align directly, requires a sophisticated solution. Inefficient maneuvering can lead to significant delays, increased wear and tear on rolling stock and infrastructure, and compromise the overall safety of operations, especially within a large and active railway industry.

What Exactly is a Heavy-Duty Railway Turntable?

A heavy-duty railway turntable is a mechanical device designed to rotate rail vehicles, typically locomotives and rail cars, through a specified angle, most commonly 180 or 360 degrees. It consists of a rotating bridge or deck supported by a central pivot, allowing rail cars placed upon it to be precisely turned. Unlike lighter-duty turntables found in automotive showrooms or turntables for consumer audio equipment, railway turntables are engineered to withstand immense loads, often measured in hundreds of tons, and the rigorous demands of continuous industrial use. Their primary function is to enable rail vehicles to change direction or move between tracks that are not directly connected, solving the spatial limitations inherent in rail network design.

The Indispensable Role: Why Heavy-Duty Turntables Are Critical for Modern Rail

Optimizing Railyard Efficiency and Traffic Flow

Heavy-duty railway turntables are instrumental in streamlining railyard operations. By enabling quick and precise rotation, they eliminate the need for lengthy and complex track switching sequences. This significantly reduces the time required to move locomotives and rail cars into position, leading to faster turnaround times for trains. In a growing locomotive market, efficient operations are crucial for handling increased traffic. Turntables allow for more compact and efficient railyard layouts, maximizing throughput and reducing operational bottlenecks.

Facilitating Access to Maintenance, Repair, and Roundhouse Facilities

Accessing rail maintenance and repair facilities is a critical function of railway operations. Locomotives and rail cars often require specialized bays or roundhouses for servicing. A heavy-duty turntable provides direct, non-complex access to these facilities, allowing operators to position vehicles precisely without needing to navigate a maze of tracks. This ease of access is vital for the efficient functioning of the substantial rail maintenance services market, estimated at $8.5bn in the US in 2025 [IBISWorld, 2025]. Prompt access speeds up repair times, minimizing downtime for essential rolling stock.

Maximizing Space Utilization in Congested Rail Environments

Space in rail yards is often at a premium. Heavy-duty turntables offer a strategic solution for maximizing this limited space. Instead of requiring extensive parallel tracks or complex switching yards to achieve directional changes, a turntable allows for a more direct radial layout. This compact design enables facilities to accommodate more rolling stock, more operational areas, or simply to maintain a less cluttered and more manageable operational space. This is particularly relevant as railway capital expenditure is increasing globally, reflecting a drive for infrastructure development and modernization.

Enhancing Safety and Precision in Maneuvering Operations

Safety is a paramount concern in the railway industry. Traditional maneuvering involving extensive reversing and complex track alignments can be hazardous, increasing the risk of derailments, collisions, and personnel injuries. Heavy-duty turntables significantly enhance safety by enabling precise, controlled rotations. Operators can position vehicles accurately without the uncertainty of manual shunting. This reduction in reversing maneuvers not only protects personnel but also minimizes damage to the locomotives, rail cars, products, and the track infrastructure itself, contributing to overall operational integrity.

The Engineering Marvel: Anatomy and Design of Heavy-Duty Turntables

Robust Load Capacity and Structural Integrity

The defining characteristic of a heavy-duty railway turntable is its formidable load capacity. These machines are engineered to safely handle the immense weight of the largest locomotives and fully loaded freight cars, often exceeding hundreds of tons. This demands robust structural integrity, utilizing high-strength steel alloys and meticulous design by experienced engineers like those at Handling Specialty Manufacturing ltd.. The quality of materials and construction is paramount to ensure the turntable can withstand the extreme stresses and cyclical loading inherent in its operation, guaranteeing longevity and reliable performance under demanding duty cycles.

Advanced Power and Drive Mechanisms

To rotate such massive loads, heavy-duty turntables employ powerful and reliable drive systems. While various mechanisms exist, robust electric or hydraulic drive systems are common. These systems are designed for precision and ample torque to initiate and control the rotation smoothly, even under full load. The drive components are selected for their durability and ability to operate efficiently in harsh industrial environments. Modern controls ensure that these powerful drives can be operated with precision by trained operators.

Critical Components for Durability and Performance

The longevity and performance of a heavy-duty turntable rely on the quality and durability of its individual components. Central to its operation are heavy-duty bearings, often large roller or slewing ring bearings, designed to support radial and axial loads while allowing for smooth rotation. The bridge structure, deck plating, and the central pivot assembly are all engineered for exceptional strength and wear resistance. Regular maintenance of these critical components is essential for sustained peak performance and to prevent costly repair needs.

Sophisticated Control Systems and Automation

Modern heavy-duty railway turntables incorporate sophisticated controls that enhance both operational efficiency and safety. These systems provide operators with precise command over the turntable’s movement, allowing for accurate positioning. Safety interlocks are integrated to prevent operation under unsafe conditions, such as if locking pins are not engaged or if personnel are detected in hazardous zones. While manual operation is standard, advanced automation and integration with yard management systems are increasingly becoming available, further optimizing traffic flow and reducing the potential for human error.

Operational Benefits & Strategic Return on Investment (ROI)

Streamlined Operations and Significant Reduction in Downtime

The implementation of a heavy-duty railway turntable directly translates into streamlined operations. By enabling quick directional changes, it significantly reduces the time trains spend waiting or maneuvering. This enhanced efficiency accelerates train turnaround times and improves overall railyard throughput. Furthermore, by facilitating easier access to maintenance bays, turntables help minimize the duration of rolling stock downtime, directly impacting operational readiness and reducing the substantial costs associated with extended repair periods.

Elevated Safety Protocols and Reduced Risk

The operational benefits of heavy-duty turntables extend profoundly to safety. Eliminating the need for complex and risky reversing maneuvers at junctions and sidings dramatically lowers the probability of derailments and collisions. This enhanced precision protects valuable rolling stock, vital infrastructure, and, most importantly, the operators and other personnel working in the yard. Adherence to stringent industry safety standards is made more achievable with the controlled environment that turntables provide, offering a tangible reduction in operational risk.

Long-Term Cost Savings and Asset Protection

While a substantial initial investment, a heavy-duty railway turntable offers significant long-term cost savings and protects valuable assets. By reducing the reliance on extensive track switching, it lowers the ongoing costs associated with maintaining complex track infrastructure. The precise maneuvering capabilities also reduce wear and tear on both the locomotive and rail car wheels and bogies, extending their operational lifespan. This translates to lower maintenance and repair expenditures over the life of the product, contributing to a strong strategic return on investment.

Versatility and Adaptability Across Rail Operations

Heavy-duty turntables are versatile products adaptable to a wide range of rail operations. They can be configured to accommodate various locomotive and rail car types, sizes, and configurations. Whether utilized in freight yards, passenger depots, industrial complexes, or maintenance facilities, their ability to orient rolling stock precisely makes them invaluable. Handling Specialty’s rail turntables are also highly customizable. To a client’s specific needs. This adaptability ensures that facilities can manage diverse fleets and operational requirements efficiently, making them a smart investment for any modern railway company.

Installation, Maintenance, and Support: Ensuring Sustained Peak Performance

The Criticality of Expert Installation and Integration

The successful implementation of a heavy-duty railway turntable hinges on expert installation and seamless integration. This process requires skilled engineers and technicians who understand the complexities of heavy rail infrastructure. A thorough site assessment, precise foundation work, and meticulous alignment are crucial to ensure the turntable operates safely and efficiently from day one. Partnering with an experienced company like Handling Specialty for installation guarantees that the product is set up to meet its designed capacity and operational parameters.

Comprehensive Maintenance Programs for Longevity and Reliability

To ensure sustained peak performance and maximize the lifespan of a heavy-duty turntable, comprehensive maintenance programs are indispensable. Regular inspections, lubrication of critical components, and checks of the drive and controls systems are vital. Following manufacturer-recommended maintenance schedules is crucial for identifying potential issues before they escalate into costly repair needs. Well-trained operators play a key role in daily checks, reporting any anomalies promptly.

The Importance of Manufacturer Support and Spare Parts

Reliable support from the manufacturer is a cornerstone of long-term turntable operation. A reputable company will provide readily available genuine spare components, technical assistance, and expert repair services when needed. This ensures that any downtime is minimized, and the turntable remains operational. The availability of specialized parts is critical for maintaining the quality and integrity of the heavy-duty product, ensuring it continues to perform within its specified capacity.

Choosing the Right Heavy-Duty Turntable for Your Facility

Key Considerations for Selection

Selecting the appropriate heavy-duty railway turntable requires careful consideration of several factors. The primary consideration is load capacity, ensuring the turntable can handle the heaviest anticipated locomotive or rail car weight in tons. The intended duty cycle, frequency of operation, and available space within the facility are also critical. The required turning radius, power supply availability, and the complexity of the desired controls all play a role in determining the most suitable product.

Customization Options and Project Scope Management

Handling Specialty’s heavy-duty railway turntables offer customization options to meet specific operational needs. This can include variations in deck length and width, specific rail gauges, or unique control interfaces. Experienced engineers can work with clients to define the project scope and tailor the product design. Effective project management by the company ensures that the installation process is efficient and aligns with the facility’s operational timeline.

Partnering with Experienced and Reputable Manufacturers

Choosing to partner with an experienced and reputable company for the supply and installation of a heavy-duty railway turntable is paramount. Such manufacturers possess the engineering expertise, manufacturing quality, and commitment to support necessary for these complex machines. Their track record in the railway industry and their understanding of heavy-duty vehicle maneuvering challenges provide assurance that the selected product will deliver reliability, safety, and long-term value.

Conclusion: Powering the Seamless Future of Rail Maneuvering

Reaffirming the Indispensable Role of Heavy-Duty Turntables

Heavy-duty railway turntables are far more than mere mechanical devices; they are foundational elements of efficient, safe, and versatile rail operations. From optimizing traffic flow in bustling railyards to ensuring critical access for maintenance and repair, their role in the modern railway industry is undeniable. The engineering that goes into their robust capacity, durable components, and sophisticated controls ensures they can handle the immense load of locomotives and rail cars with precision and reliability.

Investing in a heavy-duty turntable from a reputable company is a strategic decision that yields significant returns through enhanced operational efficiency, elevated safety protocols, and long-term cost savings. As the industry continues to grow and evolve, these vital machines will remain essential for facilitating the seamless movement of rail assets, embodying the critical interplay between robust engineering and operational necessity.