The Basics of Hydraulic Scissor Lifts

Hydraulic scissor lifts are used for precise lifting and lowering. They work using a simple but effective method. The main parts include a platform, scissor legs, a hydraulic cylinder, and a power source. The platform is where workers or materials sit while being lifted. The scissor legs open and close during use, depending on whether the lift raises or lowers.

The hydraulic cylinder gets power from electricity, diesel, or compressed air, creating the lift force. When hydraulic fluid enters the cylinder, it pushes out and spreads the scissor legs apart, lifting the platform. When the hydraulic fluid is released, the cylinder returns and the platform lowers.

Key Components and Their Functions

Hydraulic Fluid: This is the main fluid in the system. Hydraulic fluid carries power within the lift. The hydraulic pump pressurizes it and sends it into the hydraulic cylinder, creating the force needed to lift.

Scissor Legs: These steel parts connect to form a crisscross shape, hence the name scissor lifts. When the hydraulic cylinder moves, it pushes or pulls the scissor legs, causing the platform to go up or down.

Power Source: The power source gives energy to the hydraulic pump. You can choose electricity for indoor spaces, diesel for outdoor applications requiring more power, or compressed air for clean or hazardous areas. Choosing the right power source is vital for your needs and the work environment.

How Hydraulic Scissor Lifts Operate

The hydraulic pump, the primary component in the operation, initiates the process. It draws hydraulic fluid from a reservoir and delivers it into the hydraulic cylinder under high pressure, setting the lift in motion.

This pressure moves the piston inside the cylinder. As the piston moves, it extends, pushing the scissor legs apart and raising the work platform. The platform goes up, creating a stable and flat surface for workers and materials. The scissor lift can be stopped at any height to ensure precision positioning.

The process of lowering the lift is reversed. The hydraulic pump releases the pressure in the cylinder, allowing the weight of the platform or a controlled release valve to pull the piston back. As a result, the scissor legs come closer together, smoothly lowering the platform to the ground.

Types of Hydraulic Scissor Lifts and Their Uses

Hydraulic scissor lifts come in different types. They vary in size, lifting power, how they get energy, and where they are used. Knowing these types is essential for picking the right lift for the job.

Common types include:

- Table Lifts: These are small and ideally suited for lifting lighter items in tight spots. They are usually seen in assembly lines or workshops.

- Mobile Scissor Lifts: These lifts are flexible and easy to move. They can be found in warehouses, construction sites, and factories and are used for many tasks.

- Stationary Scissor Lifts: Installed in one place, these lifts work well for loading docks, production lines, or any area that requires regular lifting.

Fixed Installation vs. Mobile Units

The choice between a fixed installation and a mobile unit mainly depends on how and where you will use the lift. As the name suggests, mobile units bring excellent mobility to the work area.

Here is a closer look at the two types:

- Mobile Units:

- These are perfect for construction sites, maintenance work, and other jobs requiring frequent movement.

- They come in various sizes and weight limits to meet different needs, from small units for lighter tasks to heavy-duty models for lifting heavy loads.

- Fixed Installations:

- These provide a permanent lifting solution in certain spots, like loading docks or production lines.

- They can be customized to fit well with current workflows and space.

- Fixed installations usually handle heavier loads and provide a more stable platform than mobile units.

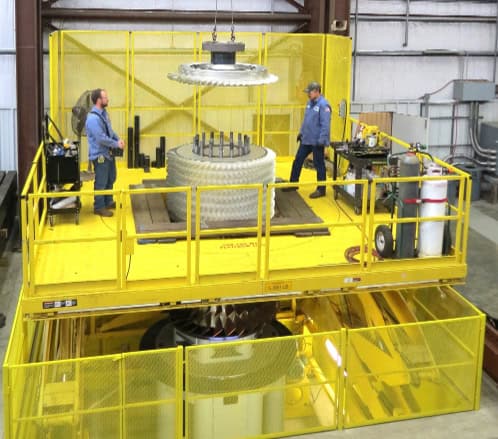

Custom Solutions for Specialized Applications

While regular hydraulic scissor lifts are great for many tasks, some situations require unique solutions. Good manufacturers know that a one-size-fits-all option doesn’t always work, so they provide choices to customize lifts according to specific needs.

Custom material handling solutions can vary greatly. They may change the size and shape of the platform, as well as the lifting height and capacity. They can also mean custom tooling like turn tables, rotators, and even a second lift system included on the platform like:

- Rotating Platforms: Help position materials or workers at different angles.

- Extendable Platforms: These give more reach, letting workers access a more extensive area from one lift position.

- Safety Features: This includes safety interlocks, emergency stop buttons, and tilt sensors to make the work area safer for operators.

- Explosion Proof: This allows heavy-duty scissor lifts to operate in hazardous environments.

Advantages of Using Hydraulic Scissor Lifts in Industry

Hydraulic scissor lifts are very useful tools in many industries. Here are some important benefits they offer:

- Enhanced Safety: They create a stable platform for workers, which lowers the chances of falls from ladders or scaffolding.

- Increased Productivity: Workers can access tall areas quickly and easily. This helps with tasks that might take a long time or be hard to do otherwise.

- Versatility: These lifts can be used in many places and for different jobs, making them valuable in various sectors.

Cost-Effectiveness Compared to Other Lifting Solutions

One significant benefit of scissor lifts is that they save money over time compared to other lifting machines. At first, the price might look similar, but you can save a lot in the long run.

First, scissor lifts are cheap to maintain. Regular check-ups usually mean looking at the hydraulic fluid levels, checking the lift mechanism, and ensuring all safety features work. Scissor lifts do not have many moving parts.

Next, they are easy to operate, which means workers only need a little training. This helps you save even more money. Finally, their strength and long-lasting parts mean they last a long time. This way, you spend less overall than you would with other lifting equipment.

Durability and Reliability in Various Environments

Hydraulic scissor lifts are designed to be durable and reliable in various industrial settings. Their robust construction and high-quality parts ensure they can withstand the rigors of industrial use, giving you confidence and reassurance in their performance.

Most models can handle harsh environments. They use weather-resistant materials and coatings to prevent rust and corrosion. The hydraulic system is reliable. It has fewer moving parts than other lifting types, which means less chance of breakage and less downtime.

Planned Maintenance of the lift also helps it last longer. Following the manufacturer’s maintenance schedule will keep it working well and extend the life of your hydraulic scissor lift. This includes tasks like:

- Lubricating moving parts: This helps to reduce friction and wear.

- Inspecting hydraulic hoses and connections to find leaks or damage.

- Checking battery condition: This applies to electric models.

- Safety Features: Reviewing your limit switches, toe bars, and fall-safe components will keep your work area free of accidents.

Key Industries Benefiting from Hydraulic Scissor Lifts

The usefulness of hydraulic scissor lifts has made them popular in many industries. They are used in fields like heavy assembly and manufacturing. Hydraulic scissor lifts are also helpful in special areas such as entertainment and the Iron and steel industry. These lifts can safely and efficiently raise people and materials, performing several cycles daily.

Here are some key industries that benefit from using hydraulic scissor lifts:

Automotive and Aerospace Applications

In the automotive industry, hydraulic scissor lifts help in assembly lines, maintenance, and repairs. Their height can be adjusted, and they have stable platforms, which allows workers to easily and safely reach vehicles at different heights.

The aerospace industry faces unique challenges. Aircraft engines are big, heavy and complex. Hydraulic scissor lifts with heavy lifting capacities and large platforms are essential for aero-engine testing and maintenance, fuselage checks, and wing repairs.

Also, hydraulic scissor lifts can be customized to fit the needs of the automotive and aerospace industries. Some are made to fit under different vehicles, while some are hung inverted. Others have special tools to handle specific parts. This adaptability makes them a great choice.

Selecting the Right Hydraulic Scissor Lift

Choosing the right hydraulic scissor lift is important. It helps with safety, performance, and getting your money’s worth. Before you decide, consider a few essential things. You must know how to use the lift, how often, carrying capacity, the work environment, and any special tooling you’ll require. Then, talk to a professional technical salesperson who will visit your site and assist in making those decisions.

Here are the main factors to keep in mind:

Factors to Consider When Buying or Commissioning

Work Environment: Where the lift will be used affects the power source and special features needed. For example, electric or hydraulic lifts are best for indoor assembly, testing, and maintenance repair operations (MRO).

Load Capacity: This is important because it tells you the maximum weight the lift can safely carry. You need to consider the total weight of the workers, tools, and materials to be lifted. Overloading can lead to serious safety problems and damage to the lift.

Customer Support and Maintenance: Check the manufacturer’s reputation for customer service. It is essential to know how quickly they respond to maintenance needs and whether spare parts are available. Regular maintenance keeps your hydraulic lift safe and helps it last longer, so good customer service is very important.

Pre-made Options vs. Bespoke Designs

The choice between a ready-made hydraulic scissor lift and a custom design depends on what you need to do and your budget. Ready-made lifts are easy to find and are a good option for standard uses. They are made in large numbers and follow industry rules, which makes them a dependable choice for everyday lifting tasks.

Custom designs, however, provide solutions made just for you. If a standard lift does not meet your needs, a custom hydraulic scissor lift can be built to fit specific weight limits, platform sizes, lifting heights, and extra features. This is required in most assembly and MRO facilities.

Even though custom designs usually cost more upfront, they can save you money in the long run by perfectly meeting your needs. Talking to a reliable manufacturer specializing in custom material handling solutions like Handling Specialty will help you get a lift designed and built to high standards. This will include all the critical features you need for your specific tasks.

![]()

Conclusion

Hydraulic scissor lifts are essential tools in many industries. They are versatile, cost-effective, and durable. These lifts help in lifting heavy loads both safely and efficiently. By understanding their parts, how they work, and the different types, industries can choose the right scissor lift for their needs. Whether used in automotive, aerospace, manufacturing, energy, or entertainment, hydraulic scissor lifts help improve productivity on your assembly line. With their reliable solutions and ability to work in different settings, hydraulic scissor lifts remain a popular choice for lifting tasks in various industries.

Frequently Asked Questions

What Makes Hydraulic Scissor Lifts a Preferred Choice in Multiple Industries?

Hydraulic scissor lifts are helpful for various applications and can be customized to suit any application requirements. They provide a sturdy base for different tasks, and their robust design makes them great for assembly and MRO facilities.