How Automation Increases the Efficiency of Manufacturing

What Is the Goal of Automation in Manufacturing?

- Improves Efficiency

- Enhances Quality

- Increases Safety

- Improves Employee Productivity

- Reduces Costs

- Easy Automation of the Manufacturing Process

Custom Material Handling Products That Help Increase Automation Efficiency

- Automated Guided Vehicles

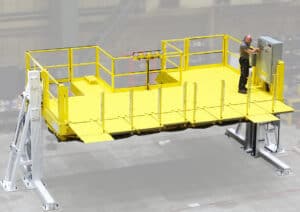

- Personnel Lifts

- Work Positioners

- Custom Scissor Lifts

- Tilters and Up enders

- Turn tables

Improve Your Assembly Automation With Quality Equipment From Handling Specialty

There are many advantages of custom manufacturing technology in this competitive sector, and with easy-to-program, custom products allowing flexibility and versatility, the benefits of custom material handling systems become clear.

Custom automated system: Our experienced engineers can design custom material handling systems tailored to your specific applications that include AGVs paired with other equipment like personnel lifts, work positioners and scissor lifts.

Cost savings –With detailed data on machine performance via sensors and IIoT to track vibrations and wear and tear over time per component, manufacturers can pinpoint and eliminate bottlenecks and inefficiencies. This directly reduces waste and drives down costs related to labor, raw materials, maintenance, downtime, and more.

With automated data collection, manufacturers gain a comprehensive overview of production metrics, asset performance and overall equipment effectiveness. This enables optimized decision making and drives productivity gains.

Invest Capital

Our data show unequivocally that capital investment in new, custom equipment is essential to sustaining growth over a long time (that is, a decade or more). But they also show that capital investment all too often reduces ROI for up to a year. Simply investing money in new technology or systems guarantees nothing. What matters is who you employ to design, install, train on and maintain your material handling equipment and how their introduction is managed, as well as the extent to which they support and reinforce continual improvement throughout a factory. Managed right, new custom equipment investment supports cumulative, long-term productivity improvement and process understanding.

Value of Learning

If setting up adequate measures of performance is the first step toward getting full competitive leverage out of manufacturing, identifying factory-level goals is the second. But without making a commitment to ongoing learning, a factory will gain no more from these first two steps than a one-time boost in performance. To sustain the leverage of plant-level operations, managers must pay close attention to—and actively plan for—learning.

What is Industry 4.0?

Known as the fourth industrial revolution, Industry 4.0 is the digital transformation of manufacturing, production and the industrial value chain.

Availability Losses

Before a company can begin to address issues caused by the Six Big Losses, it must first calculate the factory output rate. The vast diversity of industries and processes means that there will be differences from company to company. However, while measuring capacity in production is crucial, the basics of calculating capacity are the same.

Short Term

Use Current Equipment: Using current equipment may mean adding shifts in manufacturing plants that don’t have a continuous operation set-up.

Long Term

Purchase Additional Equipment: Ideally, purchasing new material handling equipment is considered when existing equipment has exhausted its maximum capacity. If this is the case, justifying such a significant capital expense will be far easier.

Workforce Skills

You count on a skilled workforce to maintain production efficiency. Operators require the proper training to effectively run their custom machines and make the best use of the tools available. You should ensure that your entire team has the required training via your OEM to troubleshoot issues, reduce setup times, and follow standardized workflows.

Custom Automated Material Handling Equipment Essentials

Equipment is an important part of an automated manufacturing system and its efficiency directly affects the quality and cost of the product contributing to the overall productivity of a company.

Train your employees

If you find that workers lack essential skills, then it is vital to invest in training employees. Companies can improve manufacturing efficiency by implementing a training program to ensure proper coordination of workers and processes through the custom equipment’s OEM.

Increase communication within and outside the company

You can use several tools to improve communication within and outside the company. You can put processes in place to track and monitor workers’ and your machines’ performance, and operations.

Maintain the material handling machines properly

If your organization is not regularly inspecting tools for efficiency, productivity may lapse. It is surprising to see how many managers look for ways to improve operational efficiency in manufacturing while neglecting the machines’ essential maintenance. Your OEM will have a planned maintenance schedule and the personnel to perform said maintenance to keep your equipment running smoothly and your business avoiding downtime.

Schedule shifts of employees

Shift scheduling in manufacturing can improve productivity by ensuring that the correct number of workers are on hand to handle the workload at any given time. This can reduce workers’ idle time, which can increase overall efficiency and productivity. Additionally, well-designed shift schedules can help reduce absenteeism and turnover, which can also positively impact productivity. Advanced scheduling software can make it easier to create and manage shift schedules, further improving efficiency.

Automate the manufacturing process

Automating your assembly, MRO or manufacturing facility is essential in bringing your operations up to date with your competitors. Discussing this major step with a qualified and experienced custom material handling design/build company will offer optimum results. Handling Specialty Manufacturing Ltd. has been creating custom equipment to automate and simplify these processes since 1963. Originally focused on the automotive industry, the company quickly diversified into other industries such as aerospace, rail and transit, advanced manufacturing, power generation, iron & steel and even entertainment. An OEM like Handling Specialty has everything in place to design, build, install, train on and maintain your original equipment.

Increased Productivity

Automation enables factories to run 24 hours daily, 365 days a year, with a predictable output. Robots and automated assembly lines help increase production volume by 3-5 times or more. Operators can monitor real-time data through human-machine interfaces, getting alerts when and even before issues occur on the factory floor. This leads to major productivity gains.

Improved Quality

Automated processes are extremely repeatable, performing assembly work precisely the same way thousands of times without wavering. This reduces defects and helps improve product quality control. Automated monitoring and sensor data also give better production visibility, with issues that can be addressed proactively rather than after products come off the line.

Flexibility

Work cells and reprogrammable logic controllers allow factories to shift between different products or adapt to design changes quickly. Assembly lines can incorporate new parts and processes through software and hardware changes rather than retooling the whole process. For example, if an assembly line with AGVs moving product through the process require the line to be altered, this can be quickly managed through simple programming changes. This makes automated plants extremely agile in bringing new products to market.

Safer Working Conditions

Automating dangerous or repetitive tasks leads to safer and more ergonomic working environments. Automation can handle tasks like heavy lifting, rotating, tilting, moving, handling, and other hazardous activities – reducing risks for human workers. This allows personnel to focus on more strategic tasks like production planning, maintenance, and Engineering.

Reduced Costs

Despite the high upfront investment, custom automation pays dividends through radically decreased operating expenses from energy savings from optimized hydraulic systems and pneumatic processes, and lower long-term labor costs. Continuous feedback loops help factories calculate and optimize the cost of production.

Assembly Lines

Automated Guided Vehicles excel at the repetitive pick-and-place work required for assembly operations. Automated assembly with technologies like pneumatic drivers and motor controllers with built-in amplification helps ensure predictable output. Components can be automatically fed into workstations from pick-and-place bins, limiting downtime.

Pro Tip

When considering automating your assembly, MRO or manufacturing facilities, review your options and discover the benefits of employing a singular company who can supply your system from design to assembly line and everything there after. If a material handling automation system is something you’ve considered, contact Handling Specialty for a consultation.