Introduction

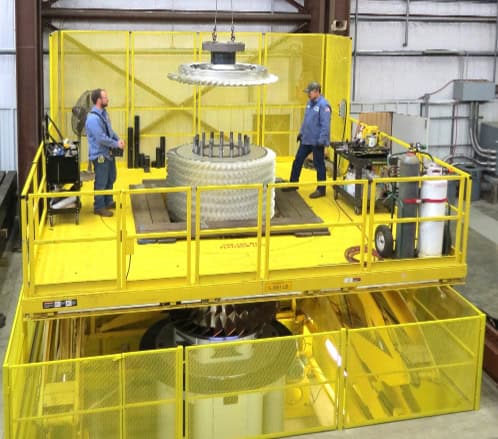

Custom personnel lifts, also known as work platforms or scissor lifts, are included in many industries, including manufacturing, assembly, painting, maintenance, and welding. These lifts provide a safe and efficient way for workers to access elevated areas, perform tasks, and handle materials. While standard lift options are available, custom personnel lifts offer tailored solutions for unique needs and challenges, providing for specific application needs.

At Handling Specialty, we understand that every industry and application is different. That’s why we specialize in designing and manufacturing custom personnel lifts that go beyond traditional scissor lifts. With our advanced experience in engineering and manufacturing, we can provide lifts that meet your specific requirements, even in designs that would not allow for a standard lift.

Our custom personnel lifts have been trusted by various industries for decades, providing reliable and advanced solutions for material handling. Whether you require a single custom personnel lift or a major turn-key project for your multinational company, our team is here to make your project a success.

Understanding Custom Personnel Lifts

Custom personnel lifts are specialized equipment used to elevate workers to different heights. These lifts are designed to provide a safe and stable platform for workers to perform tasks, access elevated areas, and handle materials. Unlike standard scissor lifts, custom personnel lifts offer tailored solutions to meet unique needs and challenges in various industries.

Defining Custom Personnel Lifts and Their Importance

These lifts are specifically designed and manufactured to go beyond standard lifts. They are crucial for material handling in industries such as manufacturing, assembly, painting, maintenance, and welding. Unlike standard lifts, which may not fit into certain designs or applications, custom lifts can be engineered to meet specific requirements. This ensures that workers can safely and efficiently access elevated areas, perform tasks, and handle materials, ultimately improving productivity and reducing the risk of workplace accidents.

The Evolution of Personnel Lifts in Various Industries

Personnel lifts, including work platforms and scissor lifts, have evolved over the years to meet the demands of assembly, MRO, and Manufacturing industries. From simple scissor lifts to advanced custom lifts, Handling Specialty has played a vital role in developing and manufacturing lifts that cater to different applications.

In the past, personnel lifts were primarily used for basic tasks in manufacturing and assembly. However, as industries have evolved, the need for more specialized lifts has emerged. Today, work platforms are used in painting, maintenance, welding, assembly, and more. Handling Specialty continues to innovate and engineer lifts that can handle the unique challenges and requirements of these industries, further enhancing efficiency and safety in the workplace.

Key Features of Custom Personnel Lifts

Custom personnel lifts offer a range of key features that set them apart from standard lifts. One such feature is the use of scissor lift tables, which provide a stable and secure platform for workers. Unlike standard lifts, custom personnel lifts are designed and manufactured to ensure they can meet specific needs and challenges.

Customization Options Available for Different Needs

Custom personnel lifts offer a wide range of customization options to cater to different needs and requirements. Some of the customization options available include:

- Height adjustments: Custom lifts can be designed to reach specific heights, ensuring that workers can access elevated areas safely and efficiently.

- Platform size and shape: The size and shape of the platform can be customized to accommodate different tasks and materials as well as move on hydraulics.

- Weight capacity: Custom lifts can be engineered to handle different weight capacities, ensuring that they can handle the specific materials being used.

- Mobility options: Depending on the needs of the application, custom lifts can be designed with mobility options such as wheels or tracks, and also include sliding bridges and additional scissor lifts on the platform.

These customization options allow businesses to tailor their personnel lifts to their specific needs, maximizing efficiency and productivity in the workplace.

Safety Features and Compliance Standards

Safety is a top priority when it comes to custom personnel lifts. These lifts are designed and manufactured to comply with industry safety standards, ensuring that workers can operate them safely.

Some of the safety features commonly found in custom lifts include:

- Guardrails: Custom lifts are equipped with guardrails to prevent falls and provide a secure working environment.

- Emergency stop buttons: These lifts are designed with emergency stop buttons that allow workers to quickly stop the lift in case of an emergency.

- Safety sensors: Custom lifts can be equipped with safety sensors that detect obstructions and prevent accidents.

- Compliance with safety standards: Custom lifts are designed and manufactured to comply with industry safety standards, ensuring that they meet the necessary requirements for safe operation.

By prioritizing safety and compliance, businesses can create a safe working environment and reduce the risk of accidents when using custom personnel lifts.

Technological Advancements in Lift Design

Technological advancements have played a significant role in the design and engineering of custom personnel lifts. With advanced experience in the industry, lift manufacturers have been able to incorporate innovative features and technologies into their designs, enhancing the overall functionality and performance of the lifts.

Some of the technological advancements in lift design include:

- Remote control operation: Custom lifts can be designed to be operated remotely, allowing for increased convenience and flexibility.

- Integrated control systems: Lifts can be equipped with advanced control systems that provide precise and smooth operation, improving efficiency and safety.

- Industrial Internet of Things capabilities: Custom lifts can be integrated with IIoT monitoring systems, allowing for real-time monitoring of lift performance and maintenance needs.

By embracing technological advancements, businesses can benefit from more advanced and efficient custom personnel lifts that enhance the overall work experience and productivity.

Benefits of Customizing Your Personnel Lift

Customizing offers a range of benefits that can positively impact your business. By tailoring the personnel lift to your specific needs and challenges, you can experience increased efficiency and productivity in the workplace. Additionally, custom lifts are designed and manufactured to be cost-effective over time, providing a long-term solution that meets your requirements while optimizing your investment.

Increased Efficiency and Productivity

Designed to enhance efficiency and productivity in the workplace, custom personnel lifts are tailored to your specific needs. You can optimize workflow and streamline tasks by designing with ergonomics in mind, allowing workers to operate more efficiently. Whether it’s accessing elevated areas, performing tasks, or handling materials, custom lifts provide a safe and efficient platform for workers to complete their work.

Handling Specialty ensures that custom lifts are designed and manufactured to maximize efficiency. With their decades of experience in engineering and manufacturing for assembly and MRO facilities, they understand the unique needs and challenges of different industries and applications, creating lifts that are specifically tailored to improve efficiency and productivity.

Enhanced Safety and Reduced Workplace Accidents

To reduce workplace accidents, custom personnel lifts prioritize safety . These lifts are designed and manufactured to comply with industry safety standards and incorporate various safety features. By providing a secure platform and implementing safety measures, custom lifts create a safe working environment for workers.

Custom lifts can be equipped with safety features such as guardrails, emergency stop buttons, and safety sensors, ensuring that workers can operate the lifts without risk. By reducing the possibility of accidents and injuries, businesses can create a safer workplace, protecting the well-being of their employees, their product, and reducing downtime due to accidents.

Cost-Effectiveness Over Time

Customizing your personnel lift can be a cost-effective investment for your business in the long run. While the initial cost of a custom lift may be higher than a standard lift, the tailored solution offers several benefits that contribute to cost savings over time.

By optimizing workflow and efficiency, custom lifts can reduce labor costs and increase productivity, ultimately saving businesses time and money. The long-term durability and reliability of custom lifts mean that they require less maintenance and have a longer lifespan, reducing maintenance costs and the need for frequent replacements.

Custom lifts are designed to meet your specific requirements, which means you only invest in the features and capabilities that are necessary for your operations. This targeted approach to customization allows businesses to optimize their investment and achieve cost-effectiveness over time.

Types of Custom Personnel Lifts

Custom personnel lifts come in various types, each designed to meet specific needs and challenges. Some of the common types of custom lifts include:

- Vertical lifts: These lifts are designed to provide vertical access, making them ideal for tasks that require a straight vertical reach.

- Scissor lifts: Scissor lifts are versatile lifts that provide vertical access while offering a stable and secure platform. They are commonly used in a wide range of industries.

- Specialized Personnel lifts: These lifts are designed for unique applications and specific industry requirements, providing tailored solutions for challenging tasks.

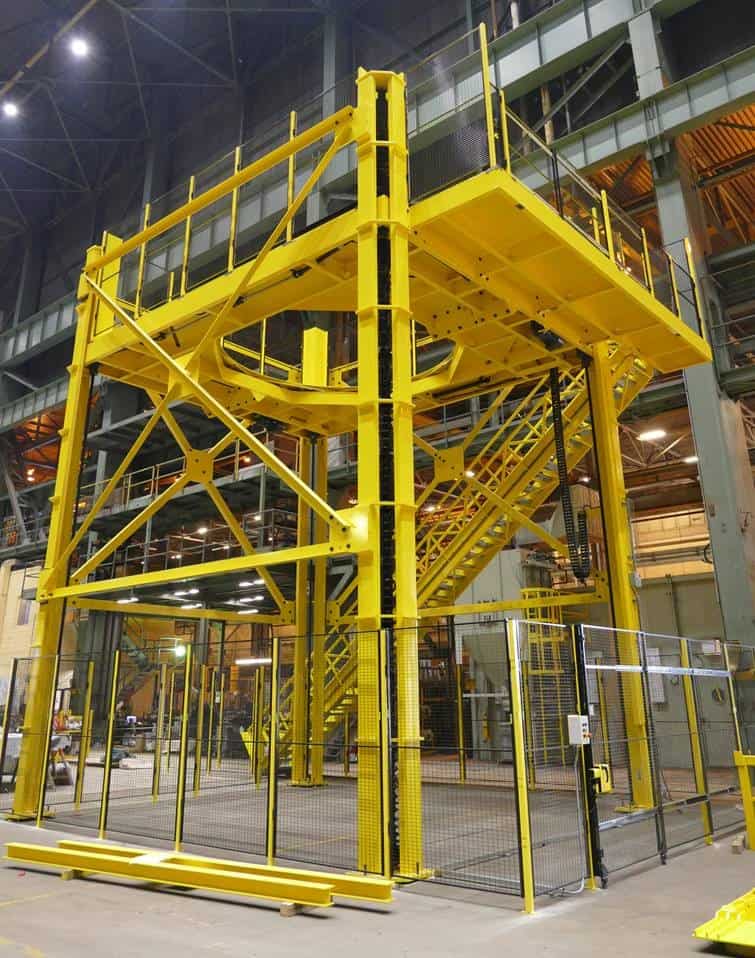

Vertical Personnel Lifts

Vertical personnel lifts are a type of custom personnel lift that features a central opening to allow for product to be assembled vertically. These lifts are commonly used in applications that require a straight vertical reach, such as assembly, inspection, and repair tasks. These vertical lifts can be installed below grade or above.

Vertical personnel lifts provide a compact and maneuverable solution for vertical assembly. This makes them ideal for tasks that require precise positioning and access to confined areas.

These lifts offer a stable and secure platform for workers, ensuring their safety while performing tasks at heights. They can be customized to reach specific heights and accommodate different weight capacities, making them versatile solutions for various industries and applications.

Scissor Lifts

Scissor lifts are one of the most common types of custom personnel lifts. These lifts feature a scissor-like mechanism that extends and retracts, allowing for vertical assembly at heights.

Scissor lifts are versatile and can be used in a wide range of industries and applications. They provide a stable and secure platform for workers to perform tasks at different heights. Unlike standard scissor lifts, custom scissor lifts can be designed and manufactured to meet specific needs and challenges.

Standard scissor lifts are a basic form of scissor lifts and are commonly used for tasks that require vertical access, such as maintenance, inspection, and assembly. They offer a cost-effective solution for businesses that need a reliable and efficient way to elevate workers and materials to different heights.

Specialized Personnel Lifts

Specialized, custom personnel lifts offer a unique experience for the industry they are developed for. Taking into consideration the specific needs of the client’s safety, technology, and tooling requirements, Handling Specialty’s technical sales and engineering departments will oversee the perfect solution. Whether it be a specialized personnel lift for assembly, MRO, inspection, testing, or manufacturing activities, a specialized personnel platform is a great investment to improve efficiencies.

Selecting the Right Custom Personnel Lift

Working with a manufacturer like Handling Specialty, that has advanced experience and can act as your greatest partner is essential.

Assessing your specific needs and requirements is the first step in selecting the right lift. Consider the tasks that need to be performed, the height requirements, weight capacities, and any special features or capabilities that may be necessary for your application. You can go over this with a qualified technical salesperson.

By partnering with a manufacturer that has advanced experience in engineering and manufacturing custom material handling equipment, you can ensure that yours is designed and manufactured to meet your specific needs, providing a reliable and efficient solution for your workplace.

Assessing Your Specific Needs and Requirements

By conducting a thorough needs assessment with Handling Specialty’s technical sales people, you can identify the key factors that will influence the design and specifications of the equipment.

Consider the following factors when assessing your specific needs:

- Tasks to be performed: Determine the nature of the tasks that will be performed using the equipment. This will help identify the required platform size, weight capacity, and reach height.

- Height requirements: Assess the maximum height that the equipment needs to reach. This will influence the design and capabilities of the lift.

- Weight capacities: Consider the weight of the materials or equipment that will be handled. This will determine the required weight capacity of the lift.

- Special features: Identify any special features or capabilities that may be necessary for your application, such as mobility options, special tooling, or additional safety features.

By conducting a thorough needs assessment, you can ensure that the custom material handling equipment is tailored to meet your specific requirements, maximizing its efficiency and effectiveness in your workplace.

Working with Manufacturers for Custom Solutions

When selecting a custom personnel lift, work with manufacturers that can provide custom solutions tailored to your specific needs. Manufacturers with advanced experience in engineering and manufacturing, like Handling Specialty, can offer the expertise and support required to design and build a custom material handling system that meets your requirements.

By working closely with manufacturers, you can communicate your needs and challenges, allowing them to develop a solution that addresses those specific requirements. Manufacturers can provide insights and recommendations based on their experience, helping you make informed decisions about the design and capabilities of the custom lift.

Additionally, manufacturers can ensure that the custom solution complies with industry safety standards and regulations, providing you with a reliable and safe solution. By partnering with manufacturers for custom solutions, you can have confidence in the performance and reliability of the lift, knowing that it has been specifically designed and manufactured to meet your needs.

Conclusion

In conclusion, custom personnel lifts offer tailored solutions to meet diverse industry needs efficiently and safely. With advancements in technology and customization options, you will enhance productivity, safety, and cost-effectiveness. Choosing the right type of solution involves assessing specific requirements and collaborating with manufacturers for custom equipment. By prioritizing safety features and compliance standards, these solutions reduce workplace accidents and ensure operational efficiency. Understanding the evolution and benefits of custom personnel lifts can significantly impact workplace productivity and safety standards.

Frequently Asked Questions

How Do I Determine the Right Type of Lift for My Needs?

Determining the right type of lift for your needs involves assessing the specific requirements of your application. Consider factors such as the tasks to be performed, height requirements, weight capacities, and any special features or capabilities needed. Working with manufacturers can also provide valuable guidance and expertise in selecting the right lift for your needs.

What are the advantages of using custom personnel lifts?

Custom personnel lifts offer several advantages, including increased efficiency and productivity, enhanced safety, and cost-effectiveness over time. These lifts can be customized to meet specific needs and challenges, providing tailored solutions that optimize workflow and improve workplace safety.

How do custom personnel lifts differ from standard models?

Custom personnel lifts differ from standard models in that they offer customization options to meet specific needs and challenges. Unlike standard lifts, which may not fit into certain designs or applications, custom lifts can be engineered to reach specific heights, accommodate different weight capacities, and incorporate special features.

What safety features should custom personnel lifts have?

Custom personnel lifts should have safety features that comply with industry standards and regulations. Common safety features include guardrails, emergency stop buttons, and safety sensors. By prioritizing safety, businesses can create a secure working environment and reduce the risk of accidents when using custom personnel lifts.