Lift systems, such as multi-post lifts, play a pivotal role in elevating productivity across various sectors. These lifts have evolved into indispensable tools for intricate assembly tasks, offering a multitude of benefits that streamline work processes, bolster worker safety, and amplify overall productivity.

The Role of Multi-Post Lifts in Manufacturing

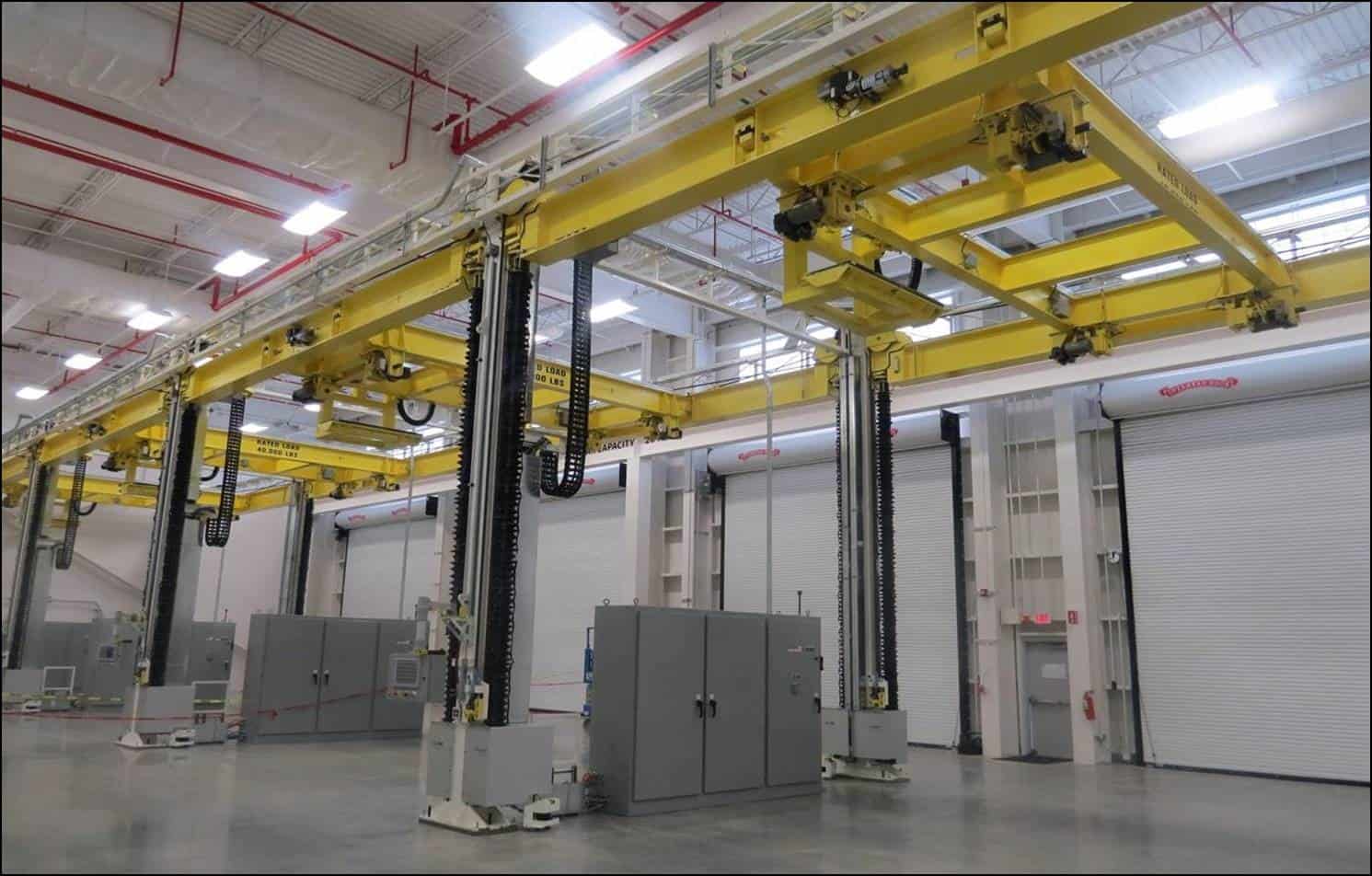

Multi-post lifts are essential tools in factories manufacturing big or complex parts. They are built to exceed required lifting capacities and have several lifting points, which gives them excellent stability and support. This helps move and place heavy items or personnel accurately.

Multi-post lifts help workers avoid strain by raising parts to comfortable working heights. Ergonomics makes their work more efficient and lowers the chance of accidents or injuries. Plus, these lifts can be used for many tasks, including initial assembly, final inspections, and maintenance.

Enhancing Efficiency in Aerospace Assembly

The aerospace industry requires high precision and careful detail during assembly work. Multi-post lifts are essential tools for building aircraft, satellites, and other aerospace parts, and they help improve operational efficiency.

These lifts can lift and support large aircraft sections, such as engines, making assembling complex systems easier. Technicians can work comfortably at different heights and angles, helping them reach essential areas for wiring, plumbing, and structural connections.

Multi-post lifts also help with preventive maintenance. They give easy access to critical parts like aircraft undercarriages and engines, allowing maintenance teams to quickly check, fix, and change parts. Doing this well and safely helps keep downtime low and aircraft ready for use.

Streamlining Energy Sector Production

The energy assembly sector depends on robust and reliable lift systems. These systems are needed to manage the large parts used in producing, moving, and delivering power. Lift manufacturers like Handling Specialty create special multi-post lifts for the energy industry. These lifts help assemble and maintain turbines, generators, transformers, and other heavy equipment.

These special lifts can carry heavy loads, are often built in pits, and are customized to the weight and size of different transformers and turbines in the energy sector. They help line up and lift heavy machines carefully during assembly. This setup lowers the chances of accidents and damage by increasing ergonomics.

Multi-post lifts are also very important for maintaining energy infrastructure. They let technicians reach high sections safely, making inspecting, fixing, and replacing them more accessible. This easy access helps cut downtime and keeps critical energy equipment running smoothly.

Advancing Rail and Transportation Manufacturing

Multi-post lifts have greatly improved the rail and transportation industry. They have excellent lifting power and can be used in many ways. They help maintain train cars and locomotives, buses, trams, and subway cars, making work safer and more efficient.

Mobile column lifts, or electric jacks, are a popular type of multi-post lift. They are well-suited for rail jobs because they can be moved easily. Technicians can bring them to the work area, so there is no need to move heavy railcars or locomotives. Mobile column lifts also have a modular design. This means they can be adjusted for different railcar sizes and wheelbases.

This type of lift offers technicians a stable and safe space. It can be used for tasks like installing underfloor equipment, fixing braking systems, or performing complete overhauls. Its use helps speed up work, boost productivity, and ensure the reliability of transportation systems.

Customization of Multi-Post Lifts for Specific Needs

Leading manufacturers recognize the unique needs of different industries and applications. They offer a wide range of customization options for multi-post lifts, ensuring they meet specific weight limits, heights, platform sizes, and safety features required for each job.

Manufacturers can adapt lifts for small spaces, add special lifting tools, or include advanced control systems. They work closely with clients to create solutions that boost functionality and safety. This teamwork ensures that the multi-post lifts fit the unique needs of each industry and use.

Tailored Solutions for Aerospace Components

Multi-post lifts offer many customization options, which help make the spaces safer and easier to reach. For example, using a rotary lift in a multi-post lift system allows workers to turn aircraft engines 360 degrees on an X or Y axis. This way, they can easily reach every side for complicated assembly tasks.

Customization also affects how platforms are built. Depending on the part being worked on, platforms can include cutouts, recesses, or adjustable sections. This helps access important areas without any blockage. Additionally, adjustable lifting hoists and special fixtures can be added. They ensure fragile aerospace engines stay stable and secure during assembly.

Customization is significant in aerospace work. The detailed nature and high value of the parts require the highest precision and control. By adjusting multi-post lifts to fit the specific demands of aerospace assembly, workers can do their jobs better and safer, creating high-quality aircraft and spacecraft.

Energy Sector Adaptations for Heavy-Duty Operations

The energy sector often deals with large, heavy parts that demand robust and stable lifting solutions. Multi-post lifts are purpose-built to meet these exacting requirements, prioritizing worker safety and equipment protection.

These lifts are engineered with safety as a top priority when handling heavy turbines and transformers. They are constructed with heavy-duty steel, robust lifting columns, and resilient hydraulic systems. Moreover, they are equipped with crucial safety features like overload protection, synchronized lifting, and automatic locks, ensuring accidents are averted and workers and valuable equipment are safeguarded.

By following industry rules and using strong components, multi-post lifts offer a safe and reliable way to work in the energy sector. They can lift the heavy weight and unique shapes of turbines, generators, transformers, and other essential equipment, helping to make the energy industry safer and more efficient.

Modular Designs for Rail Industry Applications

The different sizes and shapes of train cars require flexible lifting options. Multi-post lifts designed for the rail industry often have a modular design. This allows for easy setup to fit various railcar and locomotive sizes.

Electric jacks show this flexibility well. Their design lets technicians add or remove columns as needed, creating a lifting system that suits the length and weight of the train vehicle. This flexibility helps support and stabilize the load, which is crucial for safe maintenance or assembly work.

The modular design of these lifts helps reduce downtime and brings more flexibility to rail work. Adapting to various vehicle and wheelset sizes smoothes workflows, better uses resources, and reduces the need for many unique lifts. This leads to cost savings and greater efficiency in rail maintenance and manufacturing.

Improving Worker Safety with Advanced Lift Technologies

Multi-post lift systems help reduce injuries and create a comfortable place to work,. Improved ergonomics mean technicians do not need to stretch, bend, or hold awkward postures.

Many multi-post lifts also have helpful features. These include adjustable platforms, tilting abilities, rotating tooling, and built-in tool trays. These features make the work area more comfortable and boost efficiency. They lower fatigue and help workers be more precise when assembling, leading to a safer and more effective workspace.

The benefits of multi-post lifts go beyond just assembling. They also aid in preventive maintenance. With easy access to parts at ergonomic heights, technicians can check, lubricate, and change parts. This means less strain on their bodies and helps them do their maintenance tasks well while staying safe.

These changes highlight the actual safety and operational advantages of using multi-post lifts in the energy sector. These lifts support the long-term reliability and sustainability of assembly and maintenance repair operations (MRO) facilities by encouraging a safer workplace, simplifying maintenance tasks, and cutting down on costly downtime.

Conclusion

Multi-post lifts are essential for improving efficiency, safety, and productivity in complex assembly and MRO tasks in aerospace, energy, and transportation industries. These lifts can be customized to meet specific needs. They provide tailored solutions, ergonomic benefits, and essential safety features for risky environments. Case studies show that multi-post lifts lead to significant breakthroughs in assembly and maintenance practices. They help to make operations smoother. By focusing on worker safety and doing things more efficiently, these lifts become vital tools that support smooth production and industry advancements.

Frequently Asked Questions

What Makes Multi-Post Lifts Ideal for Complex Assemblies?

Multi-post lifts are great for complicated assemblies. They are very stable, offer many customization options, and help provide precise alignment and improve operational efficiency, allowing technicians to work on detailed parts with great accuracy and control.

How Do Multi-Post Lifts Contribute to Worker Safety?

Multi-post lifts help keep workers safe. Their ergonomic design supports natural postures and reduces strain while people do assembly work. The lifts include safety features and undergo strict testing. They also meet regulatory standards, which lowers the chance of accidents and injuries.

Can Multi-Post Lifts Be Customized for Any Industry?

Yes, they can be changed to fit the needs of almost any industry. Their modular design and adjustable features, combined with many options, allow for solutions that can handle different components and meet the unique needs of various sectors.