Underwater stage lifts have transformed live performances by enabling dynamic effects and seamless scene transitions in aquatic environments. Commonly used in theatrical productions, theme parks, cruise ships, and aquatic shows, these hydraulic or mechanical systems allow platforms to rise above and fall beneath water with precision. But with their dramatic potential comes serious responsibility — ensuring safe operation is paramount.

Here’s a detailed look at the best practices for operating underwater stage lifts safely, minimizing risks while maximizing performance quality. All of this is accomplished through your OEM, which designed, built, installed, and trained on the underwater stage lifts.

1. Understand the Engineering Behind Underwater Stage Lifts

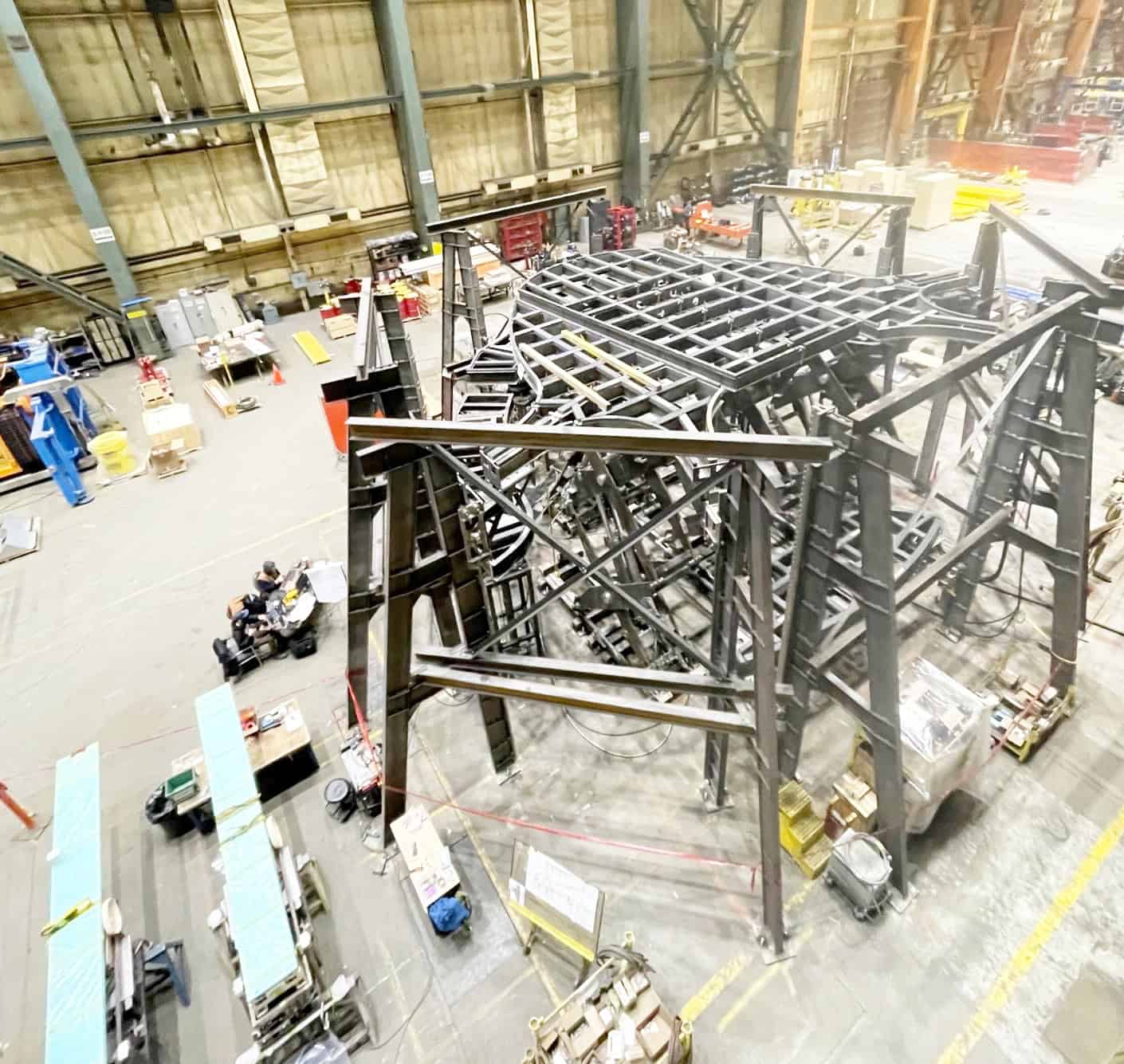

Before diving into safety procedures, operators must understand how underwater stage lifts function:

- Hydraulic or screw-drive mechanisms operate the lifts through submerged actuation.

- Water-resistant components like seals, cables, and motors prevent corrosion.

- Programmable logic controllers (PLCs) ensure precise positioning and synchronization.

Familiarity with the system’s design empowers operators to identify issues early and respond quickly to abnormalities. The OEM’s equipment manuals are an excellent guide to your underwater stage lift and should be referenced often.

2. Conduct Thorough Pre-Show Inspections

Routine pre-show checks are essential and should be included in your equipment manual. Key steps include:

- Visual inspection of lift surfaces and platforms for wear or obstruction.

- Hydraulic system checks for leaks or pressure irregularities.

- Control system diagnostics to verify operational readiness and emergency shutoff functionality.

- Divers should check underwater components.

Document all findings and avoid operating the system if abnormalities are detected. Additionally, sensors that monitor vibrations in components can be added to your stage lift system to alert you before parts become damaged, thereby avoiding downtime.

3. Implement Rigorous Training for All Personnel

Only certified and trained technicians should operate underwater stage lifts. Training from your OEM should cover:

- Basic mechanical and electrical knowledge.

- Safe lifting limits and emergency procedures.

- Real-time monitoring systems and manual override protocols.

Lifeguards, divers, stagehands, and performers should also receive safety briefings to understand the risks and signals associated with submerged platforms.

4. Coordinate Closely with Performers

For productions involving performers in the water, coordination is critical:

- Use underwater communication devices when possible.

- Establish hand signals or lighting cues to alert performers of lift movements.

- Conduct dry runs and rehearsals to align timing and positioning.

Never operate a lift while performers are unaware of its status. Have divers in the tank to coordinate with performers and check equipment.

5. Enforce a Strict Lockout/Tagout (LOTO) Policy

During stage lift maintenance, adhere to LOTO procedures to prevent accidental lift activation:

- Power down the system and use physical locks on control panels.

- Tag the system with clear warnings.

- Only allow qualified personnel to perform inspections or repairs above or below the water line.

This eliminates the risk of sudden movement while technicians are working.

6. Monitor Environmental Factors

Water temperature, chemical balance, and lighting can impact lift performance and visibility:

- Keep water within the optimal temperature and pH range.

- Ensure adequate lighting underwater to monitor lift positioning.

- Avoid high turbidity or obstructions that can cause lift misalignment.

Environmental control is as important as mechanical integrity. Most underwater stage lifts are galvanized against water corrosion.

7. Establish Emergency Protocols

Prepare for worst-case scenarios:

- Install emergency stop buttons accessible from multiple control points.

- Provide rescue and flotation equipment nearby.

- Train all team members in first aid and underwater rescue procedures.

Rehearse emergency response drills regularly to ensure readiness.

8. Schedule Preventive Maintenance

Preventive maintenance extends the life of underwater stage lifts and ensures operational safety:

- Inspect seals, pistons, and joints for wear or degradation.

- Clean and lubricate moving parts using water-safe materials.

- Calibrate sensors and control systems routinely.

Partner with manufacturers or specialists for annual inspections and upgrades.

Conclusion

Underwater stage lifts are incredible tools that bring dramatic visions to life, but their safe operation depends on strict adherence to best practices. From comprehensive staff training and routine maintenance to performer coordination and emergency preparedness, every measure contributes to a secure and spectacular aquatic show.

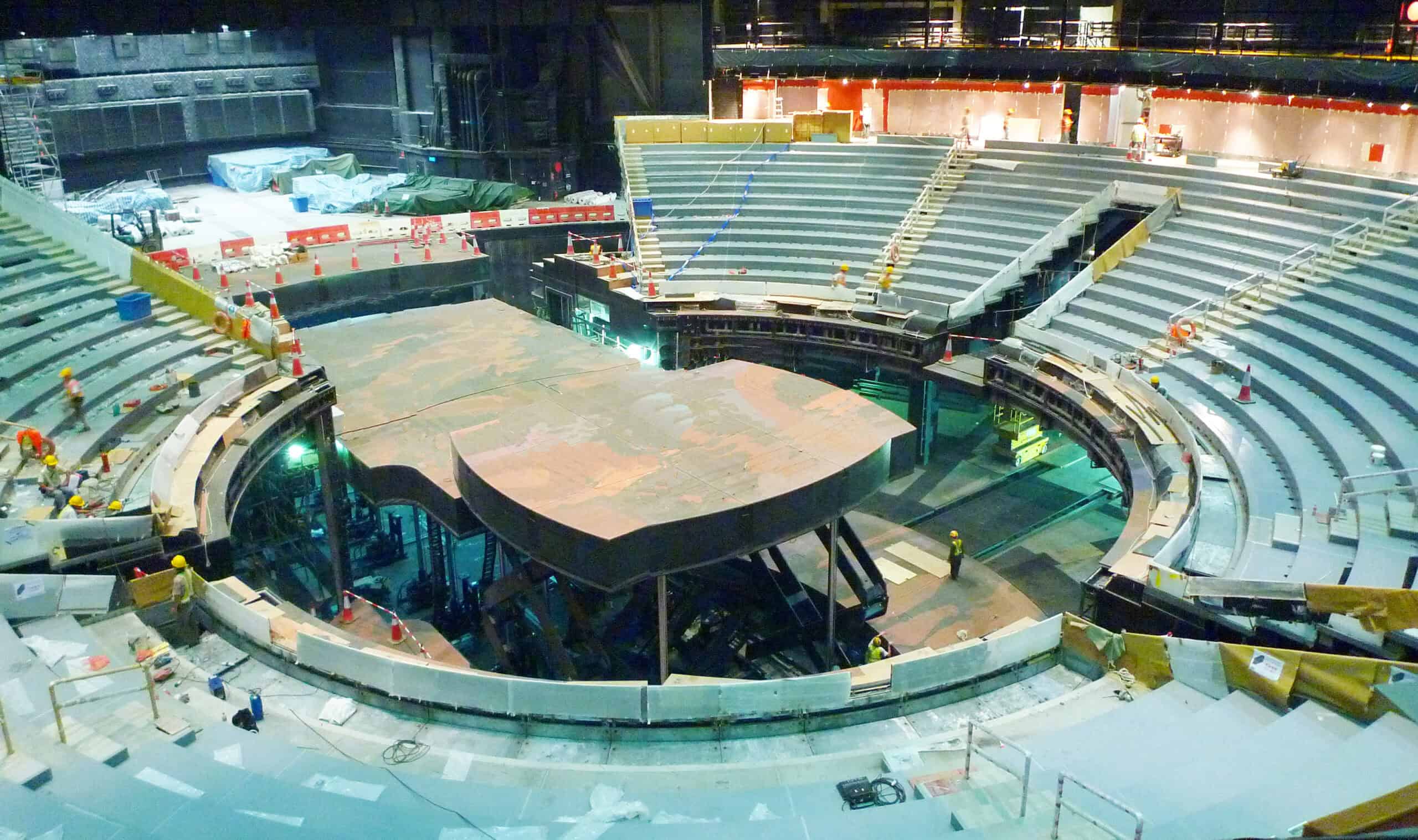

Handling Specialty has decades of experience engineering, building, installing, and training on custom underwater stage lift systems. Handling Specialty has built custom underwater stage lift systems for Cirque du Soleil, Royal Caribbean, Franco Dragone, The Bellagio, and Disney. Many of these customers have returned multiple times for more of the same.

Remember: In aquatic performance environments, safety is not an option — it’s a discipline.