The Aerospace industry has been a major customer for Handling Specialty, coming back again and again for their Custom material handling equipment needs. Handling has been awarded major contracts with tier 1 companies all over the world who understand the benefits of a material handling company that offers design engineering, manufacturing, installation, training and aftermarket services for their equipment.

Wing assembly platforms for the F-35 fighter were conceived and manufactured in Handling Specialty’s Grimsby plant. The F-35 Wing Assembly Platforms Four post, screw-driven lift design with a platform that has a customized opening to the aircraft’s wing allows access to the product from all sides and at all elevations.

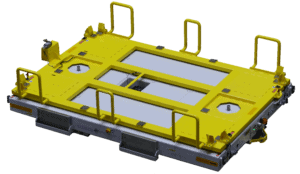

Additionally, for this project, Handling designed and built the Scissor Lift with Tilter for the F-35 wing assembly.

Another example of custom-engineered equipment for the aerospace industry includes Manually Guided Vehicles such as the Engine Dolly. This unit is used to move aero-engines around the assembly facility and comes with control panels on board for a more automated experience which allows the unit to travel through assembly operations at the will of the operator, who uses a handheld pendant. When the unit requires charging or planned maintenance, the MGV is easily parked away from the assembly floor. There are many uses for MGVs within the assembly facility of an aerospace manufacturer.

Equipment designed and built for the aerospace industry includes tooling rotisseries, service deployment systems, engine dress bay lifting systems, hydraulic lifts, engine test cells, cowling carts, mobile air traffic control towers, and engine test platforms.

Engineered-to-order solutions are what Handling Specialty is famous for in respect to material handling for assembly and manufacture of custom personnel, assembly, simulation, painting, maintenance, testing, inspection and material lifts and traversing equipment.