Introduction

The efficient maintenance of rail cars ensures smooth operations. Railway car hoist systems provide a safe and effective way to lift and support rail vehicles for inspection, repair, and maintenance. These systems are widely used in maintenance facilities across the rail industry to enhance efficiency and productivity.

Car hoist systems come in different types and configurations, each designed to cater to specific maintenance needs. They consist of critical components that contribute to their functionality and safety. The installation and implementation of these systems require careful planning and consideration of various factors.

Using car hoist systems, rail maintenance facilities can improve safety, reduce downtime, and optimize maintenance operations. These systems offer cost-effectiveness and safety improvements for workers. Let’s explore the different types of car hoist systems, their key components, installation requirements, and the benefits they bring to the rail industry. We will also look at successful case studies and ongoing innovations in car hoist technology.

Types of Railway Car Hoist Systems

Car hoist systems are a necessary part of rail industry maintenance facilities. These systems provide a safe and efficient way to lift and support rail vehicles for inspection, repair, and maintenance. By using car hoist systems, maintenance personnel can access the undercarriage of rail vehicles safely and efficiently, allowing for thorough inspections and necessary repairs. These systems are designed to handle the weight and dimensions of different types of rail vehicles, ensuring stability and safety during the lifting process.

Definition and Importance

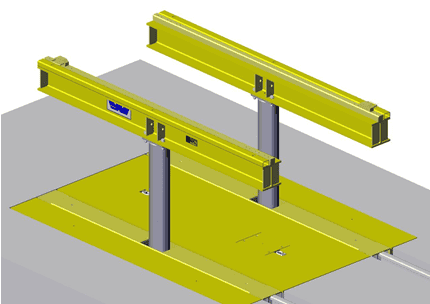

A car hoist system comes in four in-floor designs and custom above-floor designs. It is considered specialized equipment used in rail maintenance facilities to lift and support rail vehicles for inspection, repair, and maintenance. These systems are essential for efficient maintenance operations in the rail industry.

In-floor railcar hoists include

- Shallow Pit – Pass-through Lift

- Shallow Pit – Straight Lift

- Full Pit – Pass-through Lift

- Full Pit -Straight Lift

Above-floor railcar hoists include

Designed to suit individual vehicle types and facility layout

Car hoist systems are designed to handle the weight and dimensions of various rail vehicles, including light rail, freight cars, and locomotives. They provide a safe and secure lifting mechanism that allows maintenance personnel to easily access rail vehicles undercarriage. This accessibility is crucial for thorough inspections and necessary repairs to ensure rail vehicles’ safe and reliable operation.

Car hoist systems are important in the rail industry because they improve the efficiency of maintenance operations, reduce downtime, and enhance the safety of workers by providing a stable and controlled lifting environment. They are an essential investment for any rail maintenance facility.

The different car hoist systems in the rail industry are each designed to cater to specific maintenance needs. These systems include body support hoists, in-floor lifting systems, and above-floor hoists. Each system type has its advantages and is suitable for different facility designs. The choice of car hoist system depends on factors such as the type of rail vehicles being serviced, the available space in the maintenance facility, and the specific maintenance requirements.

Critical Components of a Car Hoist System

Safety features are crucial in ensuring the safe operation of the car hoist system. These features include self-locking Acme machine screws, load nut wear sensors, emergency stop buttons, and safety nut mechanisms.

The control console is the central hub of the car hoist system, allowing for the control and monitoring of the lifting process. It is equipped with controls, indicators, and displays to facilitate smooth and efficient operation.

The hydraulic pump unit provides the necessary hydraulic power to operate the lifting mechanism and supplies hydraulic pressure to the lifting jacks or other lifting equipment.

How Do Rail Car Hoists Work?

Once a car body support raises a rail vehicle, it can contact the transit vehicle’s jacking pads to support the vehicle. Once in contact, the transit vehicle’s truck/bogie can be disconnected and lowered by this car hoist to the floor/rail level for exchange.

Safety Features and Mechanisms

Safety is of utmost importance in car hoist systems to protect maintenance personnel and the integrity of the rail vehicles. Safety features and mechanisms are incorporated into car hoist systems to prevent accidents and ensure safe operation. One key safety feature is the self-locking action used in the lifting mechanism, designed to lock in place and prevent accidental lowering of the rail vehicle. These features provide stability and security during the lifting process.

Load nut wear sensors are another vital safety feature. These sensors monitor the wear and tear of the load nut, providing early detection of any potential issues. The system will shut down if abnormal wear is detected to prevent further damage or accidents.

Emergency stop buttons are strategically placed within reach of the operator to quickly halt the lifting process in case of an emergency or unsafe condition. These buttons provide an immediate means of stopping the system to prevent accidents or injuries.

For additional safety features, speak with your design/build contractor.

Maintenance and Durability Enhancements

Maintenance and durability enhancements include features and design considerations that improve maintenance, accessibility, and durability.

One crucial maintenance enhancement is easy access to critical components for routine maintenance and inspections. This can include removable covers, access panels, and clearly labeled maintenance points.

Durability enhancements can include features such as oil bath lubrication for the lifting screws or hydraulics, which improves performance and extends the wear life of the components. Other durability enhancements should include using high-quality materials and coatings to protect against corrosion and wear.

By incorporating maintenance and durability enhancements, Handling Specialty’s car hoist systems can be optimized for long-term use, reducing the need for frequent repairs and minimizing downtime.

Implementation and Installation

The implementation and installation of car hoist systems require skilled technicians who come from or are recommended by the design/build company. This process involves challenges and considerations related to installation space, support systems, and overall facility design.

Planning and design considerations include assessing the dimensions and weight of the rail vehicles to ensure that the car hoist system can accommodate them. Proper planning is necessary to determine the optimal location and layout of the system to maximize efficiency and accessibility. Handling Specialty has been designing/building and installing rail car hoist systems for decades and understands the importance of doing it right.

Installation challenges may include working within existing infrastructure and coordinating with other trades involved in the construction or renovation of the maintenance facility. Additionally, support systems, such as electrical power supply, control systems, and safety features, must be appropriately integrated into the installation.

Planning and Design Considerations

When planning and designing the installation of a car hoist system, several considerations must be taken into account to ensure the system meets the specific needs of the maintenance facility. First, the dimensions and weight of the rail vehicles the hoist system will service must be assessed. This information is crucial for determining the system’s capacity and size requirements.

The available space in the maintenance facility must also be considered. The hoist system should be positioned for easy access and efficient operation.

Other factors to consider include electrical power supply, control systems, safety features, and integration with other systems in the facility.

By carefully considering these planning and design considerations, the installation of a car hoist system can be optimized for efficient and safe operation.

Installation Challenges and Solutions

Installing a car hoist system can present challenges, especially when working within existing infrastructure or coordinating with other trades involved in the construction or renovation of the maintenance facility.

One common challenge is installing the hoist system in a limited space. This requires careful planning and design to ensure the system fits within the available area without compromising functionality or safety.

Another challenge is coordinating with other trades and ensuring that the installation of the hoist system aligns with the overall construction or renovation schedule. Effective communication and stakeholder coordination can help minimize disruptions and ensure a smooth installation process.

Proper planning, collaboration, and communication are key to overcoming these challenges. Working closely with experienced professionals who specialize in car hoist system installations can help identify potential challenges and develop effective solutions.

Efficiency in Maintenance and Repair Operations

Car hoist systems significantly improve the efficiency of maintenance and repair operations in rail maintenance facilities. By providing a safe and efficient way to lift and support rail vehicles, these systems allow maintenance personnel to easily access the undercarriage for inspections and repairs.

With car hoist systems, maintenance tasks can be completed quickly and accurately, reducing downtime. The ability to lift and support rail vehicles precisely ensures that maintenance personnel can perform thorough inspections and necessary repairs.

Efficient maintenance and repair operations contribute to the reliable operation of rail vehicles, minimizing disruptions to service and improving the overall performance of the rail system.

Conclusion

In conclusion, rail car hoist systems enhance operational efficiency, worker safety, and cost-effectiveness over time. The key components, such as safety mechanisms and control systems, ensure optimal performance. By leveraging these systems, transit agencies have witnessed significant improvements in maintenance operations and worker safety. As technology advances, customization options and innovations in car hoist systems continue to shape the future of rail car maintenance practices, making them a valuable investment for the industry.

Frequently Asked Questions

How do car hoist systems enhance safety during maintenance?

Car hoist systems enhance safety during maintenance by providing safety features and mechanisms, such as self-locking, load nut wear sensors, emergency stop buttons, and safety nut mechanisms. These features ensure rail vehicles’ secure lifting and support and prevent accidents.

What are the primary considerations when choosing a car hoist system?

The primary considerations when choosing a car hoist system include vehicle dimensions, lifting capacity, safety features, maintenance facility requirements, and efficiency needs. Evaluating these factors ensures that the selected system meets the specific needs of the rail maintenance facility.

Can car hoist systems be customized for different railway vehicles?

Yes, car hoist systems can be customized to accommodate different railway vehicles by Handling Specialty. The design and specifications of the system can be tailored to handle the weight, dimensions, and specific maintenance requirements of various rail vehicles, including light rail, freight cars, and locomotives.